Mixing device for combustion production of new energy biomass particles

A technology of biomass particles and mixing devices, which is applied in the direction of biofuels, mixers, waste fuels, etc., to achieve the effects of easy removal, improved work efficiency, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

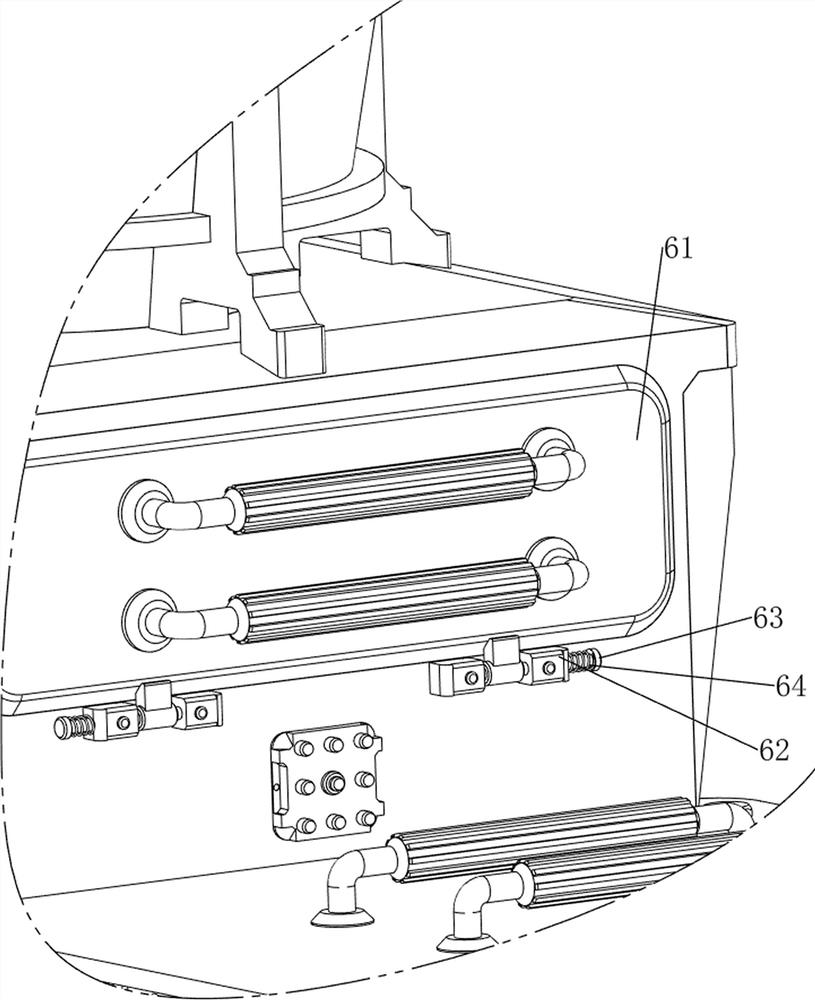

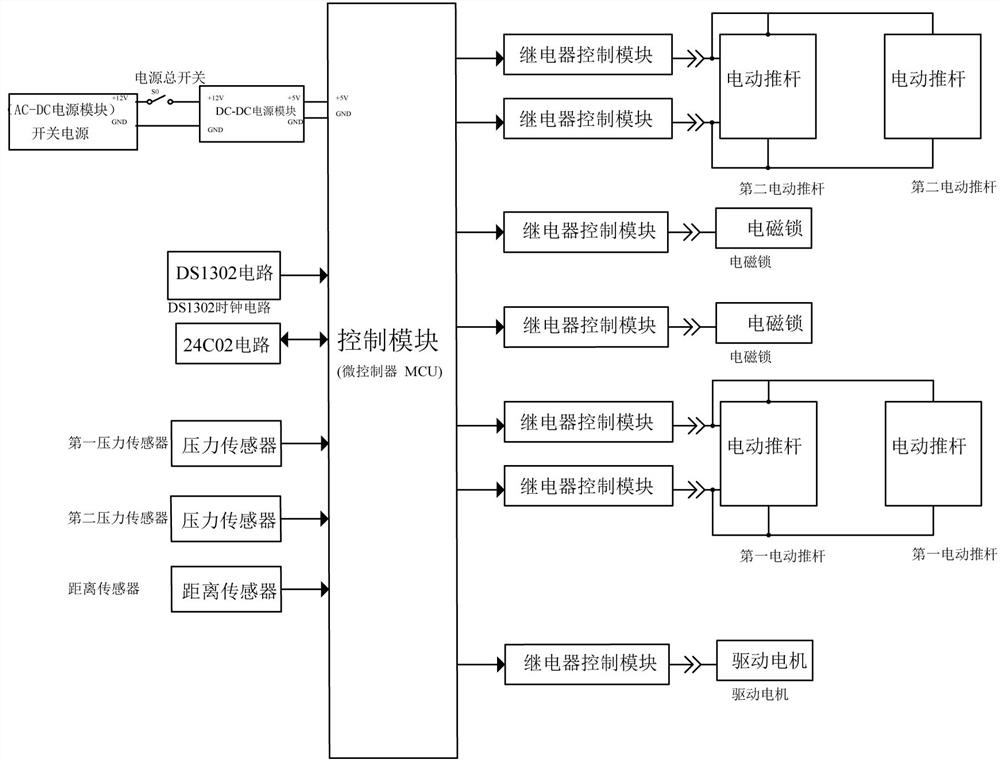

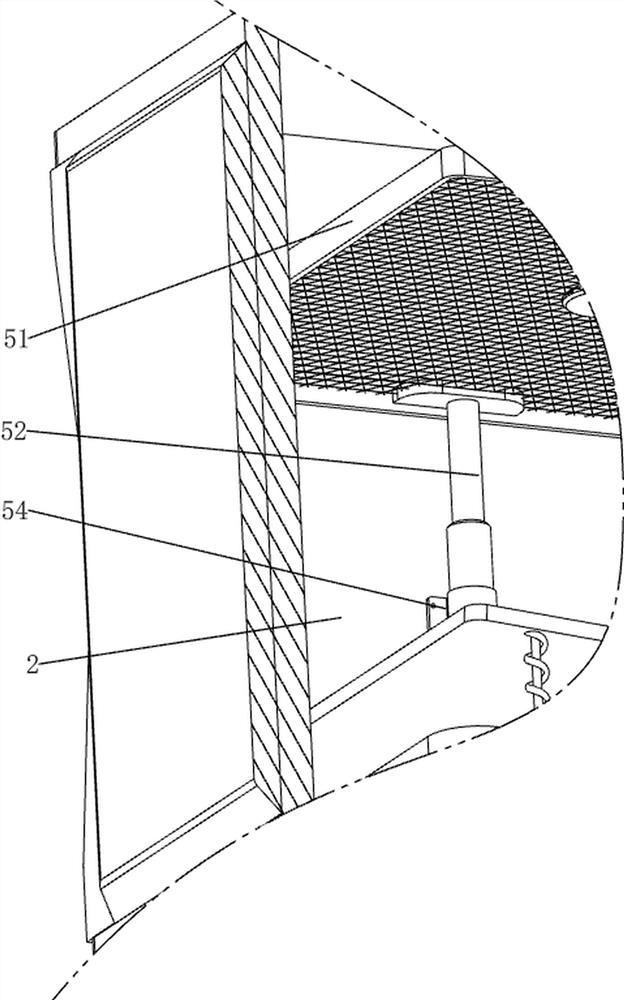

[0042] A mixing device for new energy biomass particle combustion production, including a bottom plate 1, a first working box 2, a control box 3, a first rotating shaft 31, a first fixing part 32, a cutting part 33, a mixing mechanism 4, and a toggle mechanism 5. Collecting mechanism 6 and discharging mechanism 7, see Figure 1-Figure 13 As shown, the first working box 2 is welded on the left side of the top of the bottom plate 1, and a rubber pad is connected to the four corners of the bottom of the bottom plate, the rubber pad increases the friction with the ground to prevent slipping, and the upper right side of the first working box 2 is provided with The control box 3 is provided with a first fixing part 32 in the middle of the upper part of the first working box 2, and a first rotating shaft 31 is arranged in the middle of the bottom of the first fixing part 32, and a cutting part 33 is arranged on the upper side of the first rotating shaft 31. The cutting part 33 When r...

Embodiment 2

[0049] On the basis of Embodiment 1, a dust-proof mechanism 8 is also included. The dust-proof mechanism 8 includes a blanking frame 81, a second cover plate 82, a third rotating shaft 83 and a second torsion spring 84. See figure 1 , figure 2 , image 3 , Figure 14 and Figure 15 As shown, the top of the first working box 2 is welded with a blanking frame 81, and the left side of the blanking frame 81 top is rotatably provided with a third rotating shaft 83, and the third rotating shaft 83 is provided with a second cover plate 82, and the second cover plate 82 After turning and closing, it can prevent the raw materials from flying outwards when being chopped. The second cover plate 82 blocks the top of the blanking frame 81, and a second torsion spring 84 is provided between the front side of the third rotating shaft 83 and the blanking frame 81.

[0050] When people need to load raw materials, the second cover plate 82 can be rotated to open, the second cover plate 82 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com