Preparation method of C12 tertiary alkyl primary amine

A technology of tertiary alkyl primary amines and propylene tetramers, which is applied in the field of compound preparation, can solve the problems of cumbersome production methods, high cost, and difficult wastewater treatment, and achieve the goals of reducing unit consumption, reducing pollution, and reducing the total amount of wastewater Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

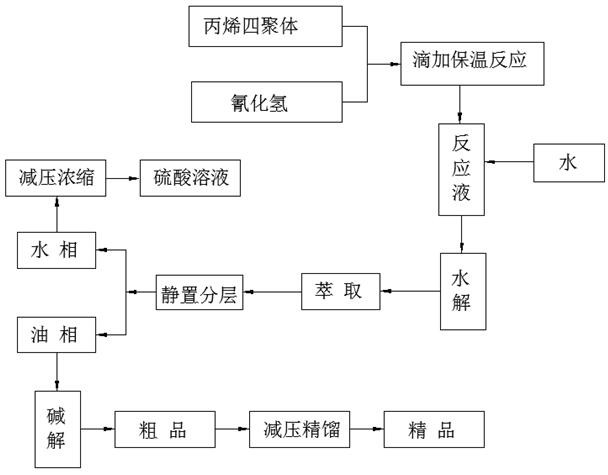

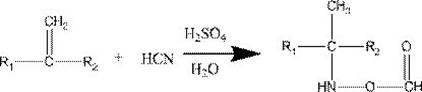

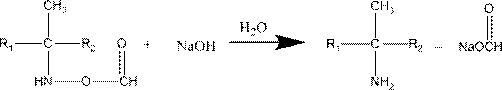

Method used

Image

Examples

Embodiment 1

[0029] (1) Add organic raw materials and hydrogen cyanide dropwise and keep warm

[0030] Weigh 100g of propylene tetramer (purity above 99%) in the reaction vessel, add 95g of 80% sulfuric acid solution (newly prepared or re-coated) dropwise to the reaction vessel through the constant pressure dropping funnel, about 1min Finally, add 18.5g of hydrogen cyanide into the reaction vessel through a constant-pressure dropping funnel, control the cooling temperature and dropping speed, and ensure that the temperature of the reaction solution is below 30°C;

[0031] The dropping speed of sulfuric acid solution and hydrogen cyanide is set, and the dropwise addition can basically be completed at the same time. After the dropwise addition, the temperature is stepped up, and the temperature is kept at 30°C, 40°C, and 50°C for 1 hour respectively.

[0032] (2) Hydrolysis, extraction, separation

[0033] After the heat preservation is over, add 100g of water to the reaction solution, stir...

Embodiment 2

[0037] (1) Add organic raw materials and hydrogen cyanide dropwise and keep warm

[0038] Weigh 100g of propylene tetramer (purity above 99%) in the reaction vessel, add 112g of 80% sulfuric acid solution (newly prepared or returned) dropwise to the reaction vessel through the constant pressure dropping funnel, about 1min Finally, add 18.5g of hydrogen cyanide into the reaction vessel through a constant pressure dropping funnel, control the cooling temperature and the dropping speed, and ensure that the temperature of the reaction solution is below 30°C;

[0039] The dropping speed of sulfuric acid solution and hydrogen cyanide is set, and the dropwise addition can basically be completed at the same time. After the dropwise addition, the temperature is stepped up, and the temperature is kept at 25°C, 35°C, and 60°C for 2 hours each.

[0040] (2) Hydrolysis, extraction, separation

[0041] After the heat preservation is over, add 100g of water to the reaction solution, stir at...

Embodiment 3

[0045] (1) Add organic raw materials and hydrogen cyanide dropwise and keep warm

[0046] Weigh 100g of propylene tetramer (purity above 99%) in the reaction vessel, add 76g of 80% sulfuric acid solution (newly prepared or returned) dropwise to the reaction vessel through the constant pressure dropping funnel, about 1min Finally, add 18.5g of hydrogen cyanide into the reaction vessel through a constant pressure dropping funnel, control the cooling temperature and the dropping speed, and ensure that the temperature of the reaction solution is below 30°C;

[0047] The dropping speed of sulfuric acid solution and hydrogen cyanide is set, and the dropwise addition can basically be completed at the same time. After the dropwise addition, the temperature is stepped up, and the temperature is kept at 30°C, 40°C, and 70°C for 1.5h each.

[0048] (2) Hydrolysis, extraction, separation

[0049] After the heat preservation is over, add 100g of water to the reaction solution, stir at 95°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com