Electrostatic adsorption dust-free coating for laboratory as well as preparation method and use method of electrostatic adsorption dust-free coating

An electrostatic adsorption and laboratory-used technology, applied in the direction of conductive paint, coating, covering/lining, etc., can solve the problems of poor electrical insulation performance, decreased instrument sensitivity, and reduced light transmittance and reflectivity of optical instruments. The effect of good film-forming performance, excellent washing resistance and good wrapping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

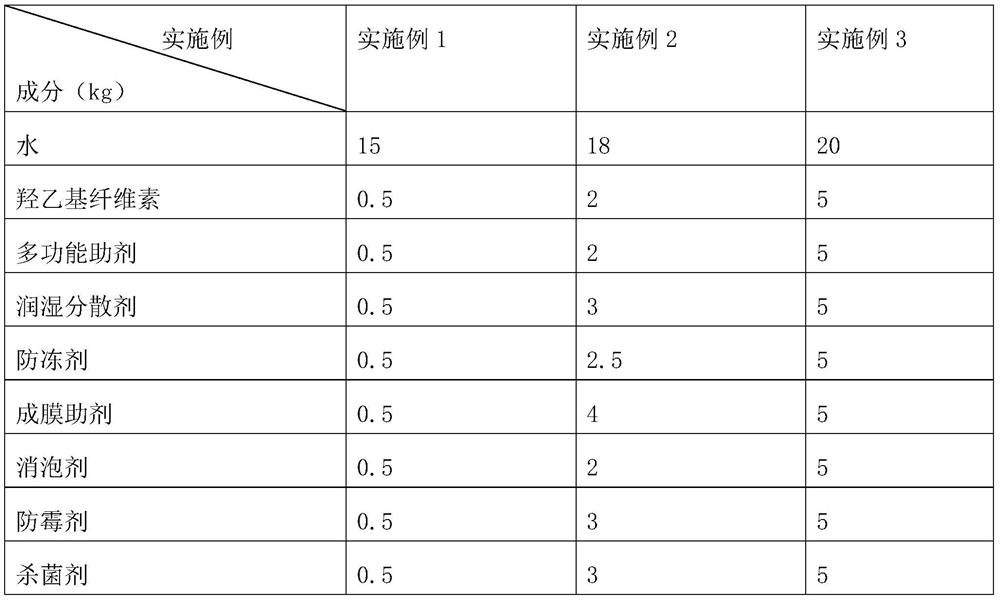

[0036] Taking the ingredients in Example 1 as an example, a preparation method for a laboratory electrostatic adsorption dust-free coating comprises the following steps:

[0037] Step 1: first add water to the stirring equipment, add hydroxyethyl cellulose in the stirring state of the stirring equipment, and stir until the hydroxyethyl cellulose has no agglomeration;

[0038] Step 2: Add multifunctional additives, wetting and dispersing agents, antifreeze agents, film-forming additives, defoamers, antifungal agents, and fungicides in sequence; and stir and disperse the above ingredients evenly;

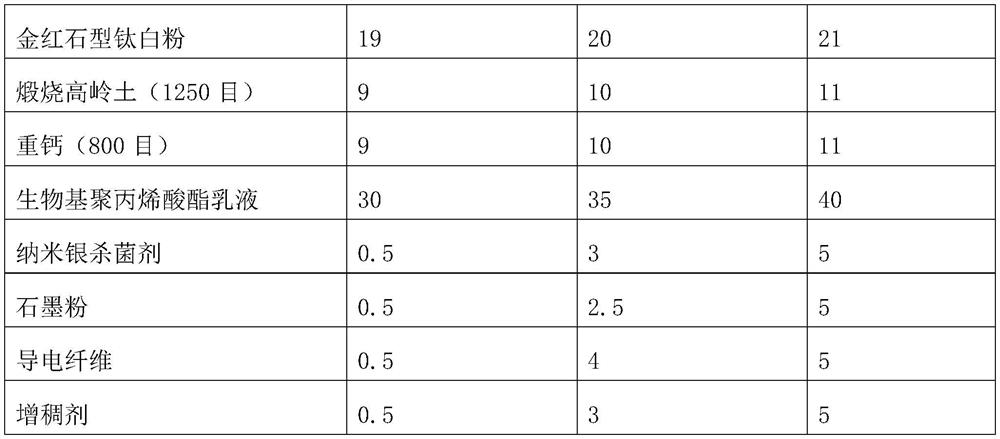

[0039] Step 3: Add titanium dioxide, kaolin, and heavy calcium, and perform high-speed stirring (stirring speed is 1000-1200r / min), until the fineness of the stirred materials is ≤60 μm;

[0040] Step 4: Then carry out medium-speed stirring (stirring speed is 500-600r / min), and add bio-based polyacrylate emulsion, nano-silver fungicide, graphite powder, conductive fiber in sequence, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com