Method for effectively analyzing microplastics in grease-containing food sample

A technology of microplastics and samples, applied in the field of environmental testing, can solve the problems of increasing filtration time, unreachable, difficult to wash the filter membrane with pure water, etc., and achieve the effects of Raman characterization, low digestion temperature, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

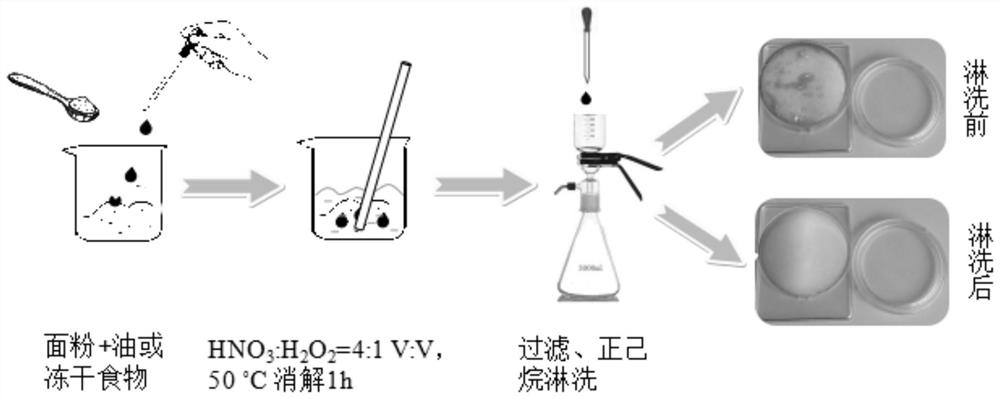

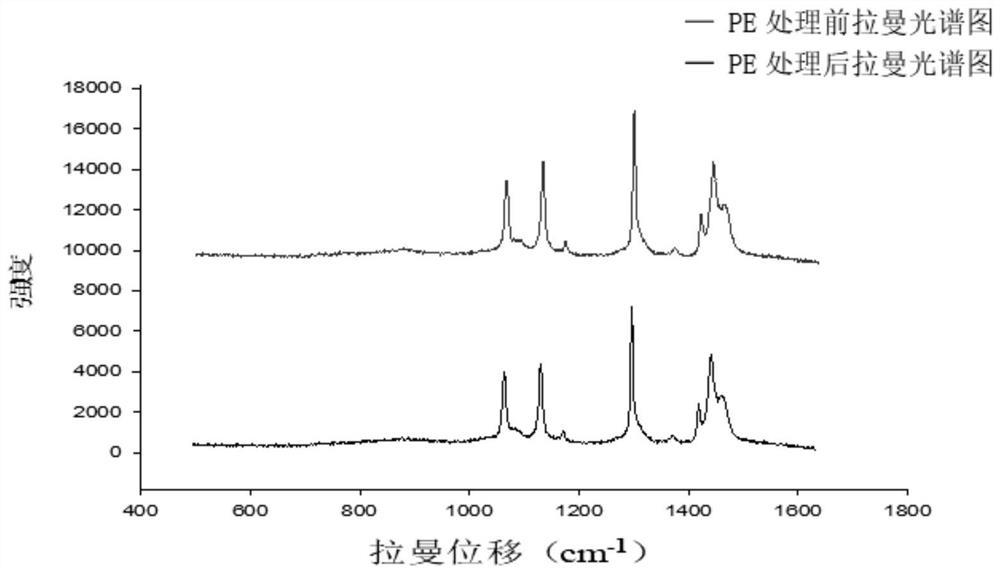

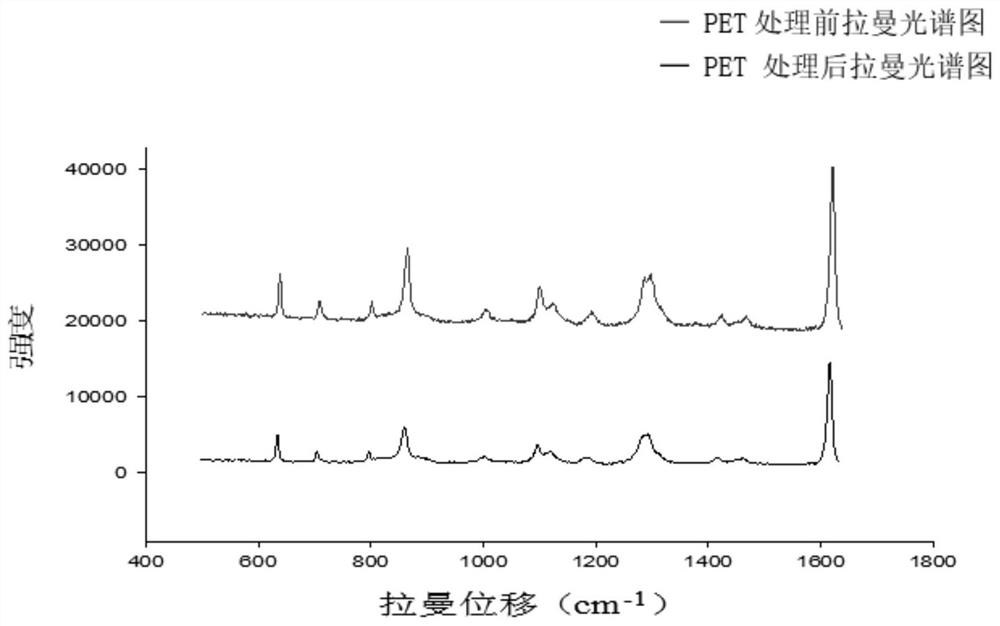

[0034] Example 1: Determination of Microplastics in Food Samples Containing Animal Oil and Flour

[0035] (1) Weigh 5g of the collected flour food sample (ie N≤5g) by weight (wet weight) in a beaker, add 0.2g of animal oil to the beaker, and add possible target substances (500μm PE, PET, PP, PS), stir and mix evenly with a glass rod.

[0036] (2) Add 50mL of digestion solution (HNO3:H2O2=4:1V:V) to the sample, shake it manually for 15s to make the digestion solution fully contact and react with the food sample, then put it in a water bath at 50°C and heat for 1h. During every 15min, manually oscillate for 15s.

[0037] (3) After the digestion is complete (when the sample and the digestion solution are relatively clear), use a nitrocellulose membrane, a suction filter device and a diaphragm vacuum pump to filter.

[0038] (4) After the digestion solution is filtered, rinse the beaker three times with pure water, pour the rinse solution into the filter cup together, and then f...

Embodiment 2

[0041] Example 2: Determination of microplastics in food samples containing animal and vegetable oil flour

[0042](1) Weigh 5g (wet weight) of the collected flour food sample into a beaker, add 0.2g of animal and vegetable oil into the beaker, and add possible target substances (500μm PE, PET, PP , PS), stir and mix well with a glass rod.

[0043] (2) Add 50mL of digestion solution (HNO3:H2O2=4:1V:V) to the sample, shake it manually for 15s to make the digestion solution fully contact and react with the food sample, then put it in a water bath at 50°C and heat for 1h. During every 15min, manually oscillate for 15s.

[0044] (3) After the digestion is complete (when the sample and the digestion solution are relatively clear), use a nitrocellulose membrane, a suction filter device and a diaphragm vacuum pump to filter.

[0045] (4) After the digestion solution is filtered, rinse the beaker three times with pure water, pour the rinse solution into the filter cup together, and ...

Embodiment 3

[0048] Example 3: Determination of Microplastics in Food Samples Containing Vegetable Oil Flour

[0049] (1) Weigh 5g of the collected flour food sample (i.e. N≤5g) by weight (wet weight) in a beaker, add 0.2g of vegetable oil into the beaker, and add possible target substances (500μm PE, PET, PP, PS), stir and mix evenly with a glass rod.

[0050] (2) Add 50mL of digestion solution (HNO3:H2O2=4:1V:V) to the sample, shake it manually for 15s to make the digestion solution fully contact and react with the food sample, then put it in a water bath at 50°C and heat for 1h. During every 15min, manually oscillate for 15s.

[0051] (3) After the digestion is complete (when the sample and the digestion solution are relatively clear), use a nitrocellulose membrane, a suction filter device and a diaphragm vacuum pump to filter.

[0052] (4) After the digestion solution is filtered, rinse the beaker three times with pure water, pour the rinse solution into the filter cup together, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com