Method for manufacturing aircraft ground comprehensive support test equipment cable

A technology of comprehensive guarantee and testing equipment, applied in the direction of cable/conductor manufacturing, equipment for connecting/terminating cables, circuits, etc., can solve problems such as protective sleeves, wire damage, connector wear, pin shrinkage, etc., so that it is not easy to fall off , easy maintenance and short production length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] All features disclosed in this specification, or steps in all methods or processes disclosed, except mutually exclusive features and / or steps, may be combined in any way and, unless specifically recited, may be otherwise equivalent or have similar Alternative features are intended to be replaced, ie, unless expressly stated otherwise, each feature is only one embodiment of a series of equivalent or similar features.

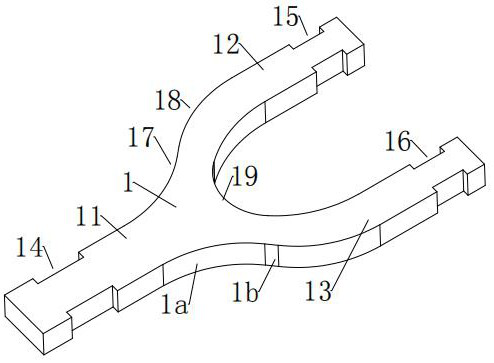

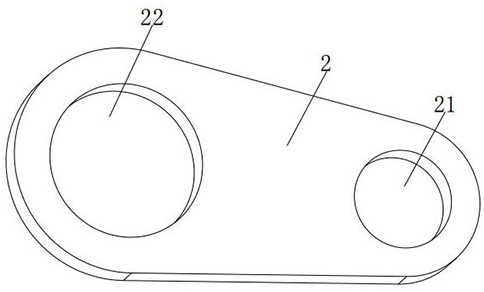

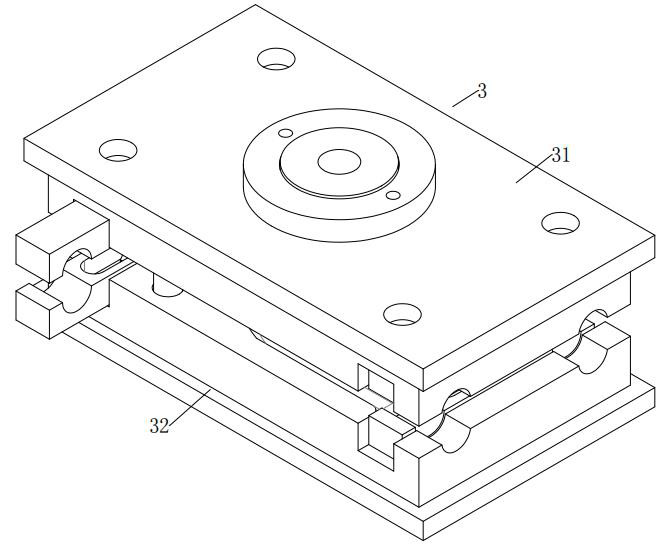

[0043] see figure 1 , figure 2 , a method for making an aircraft ground comprehensive support test equipment cable in the numerous embodiments of the present invention, comprising the following steps:

[0044] Step 1, select PU tube as the outer sheath; among them, PU tube (POLYURETHANE TUBING) has tensile strength, strong tension, high tear strength, abrasion resistance, corrosion resistance, bending resistance, penetration resistance, low temperature resistance, Hydrolysis resistance and other properties; for example, PU tube chooses polyester PU tube...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com