Micro light-emitting chip assembly and manufacturing method thereof, and micro light-emitting chip transfer method

A technology of light-emitting chips and manufacturing methods, which is applied in the fields of semiconductor/solid-state device manufacturing, electrical components, and electric-solid-state devices, etc., can solve the problems of complex transfer process, low transfer success rate, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

application example 1

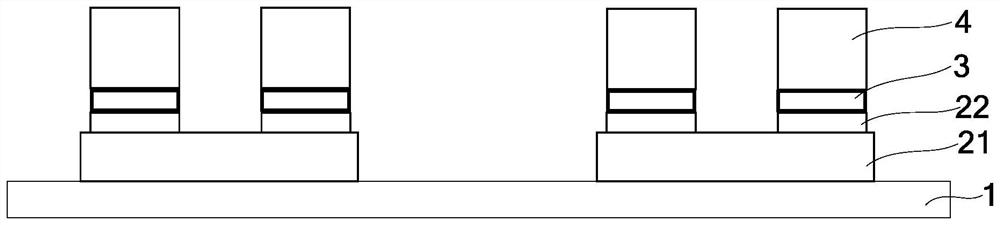

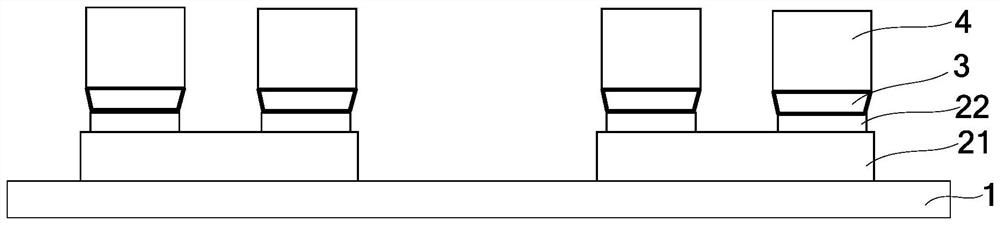

[0105] Please refer to Figure 10-1 to Figure 10-2 shown, including but not limited to:

[0106] S1001: Provide a first substrate 1 on which micro light-emitting chips are grown.

[0107] In this application example, the epitaxial layer 21 can be grown epitaxially on the first substrate 1 , and then the electrode 22 can be fabricated on the epitaxial layer.

[0108] S1002: Form independent thin film layers 3 on the electrodes of the micro light-emitting chips on the first substrate 1 respectively.

[0109] In this embodiment, the form of each micro light emitting chip on the first substrate 1 is that the electrode of each micro light emitting chip is exposed upward, and a layer of lithium fluoride thin film is formed on the electrode 22 of each micro light emitting chip by evaporation. Layer 3 has water-swelling characteristics, that is, the film thin layer will swell after absorbing water, so that the contact surface of the surface in contact with it becomes smaller.

[01...

application example 2

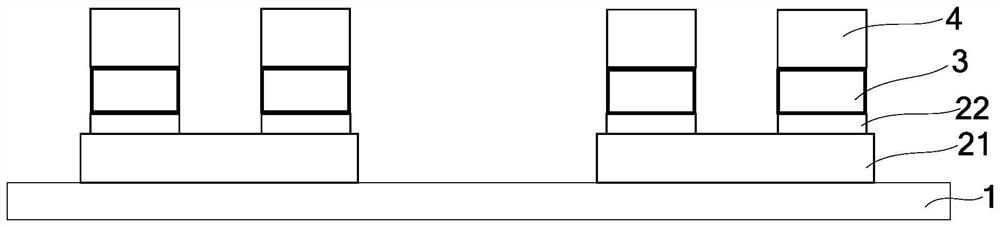

[0133] Please refer to Figure 11-1 to Figure 11-2 shown, including but not limited to:

[0134] S1101: Provide a first substrate 1 on which micro light-emitting chips are grown.

[0135] In this application example, the epitaxial layer 21 can be grown epitaxially on the first substrate 1 , and then the electrode 22 can be fabricated on the epitaxial layer.

[0136] S1102: Form independent thin film layers 3 on the electrodes of the micro light-emitting chips on the first substrate 1 respectively.

[0137] In this embodiment, the form of each micro light emitting chip on the first substrate 1 is that the electrode of each micro light emitting chip is exposed upward, and a layer of organic porous material is formed on the electrode 22 of each micro light emitting chip by evaporation. The thin film layer 3 has the property of swelling upon water absorption, that is, the thin film layer swells after absorbing water, so that the contact surface of the surface in contact with it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com