Active clamping type high-frequency chain inverter

A high-frequency transformer and high-frequency link technology, which is applied in the field of active-clamp high-frequency link inverters, can solve the problems of large clamp capacitor capacity requirements, difficulty in popularization and application, and small output voltage, so as to achieve small capacity requirements and improve inverter performance. Efficiency, volume and cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

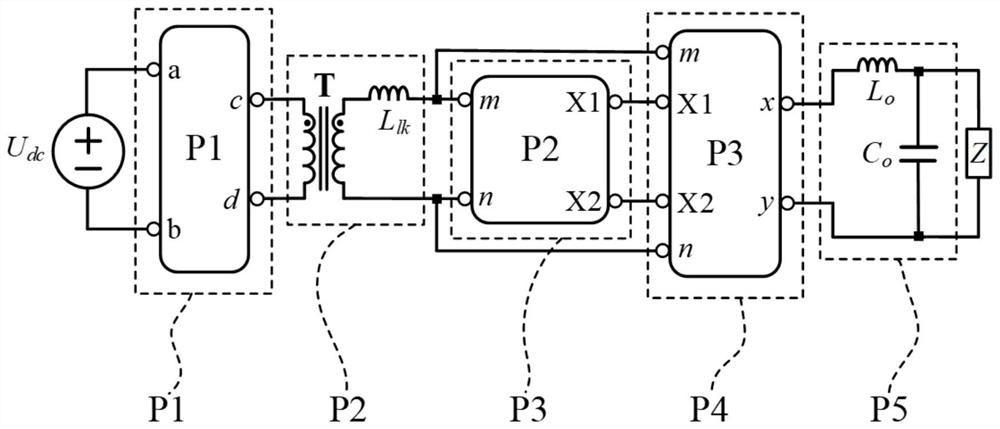

[0037] Such as figure 1 As shown, the active-clamp high-frequency link inverter provided by the present invention includes a primary-side conversion circuit, a high-frequency transformer, an active clamp circuit, a secondary-side conversion circuit, and a low-pass filter. The primary conversion circuit is an inverter circuit, including a full-bridge circuit, a half-bridge circuit, a push-pull circuit, etc., the input is connected to a DC power supply, and the output is connected to the input terminal of a high-frequency transformer.

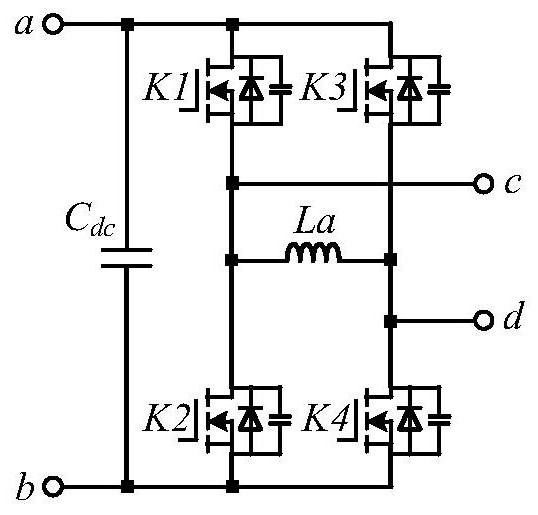

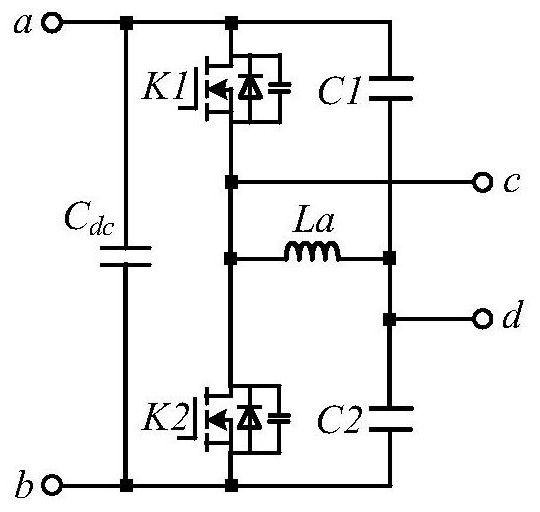

[0038] Such as figure 2 Shown is a full-bridge inverter circuit; image 3 Shown is a half-bridge inverter circuit.

[0039] The active clamping circuit includes an active clamping bridge and a clamping capacitor, and the output side of the active clamping bridge is connected in parallel with the clamping capacitor. The active clamp bridge is a full bridge structure, including four tubes: upper left tube, lower left tube, upper right tube, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com