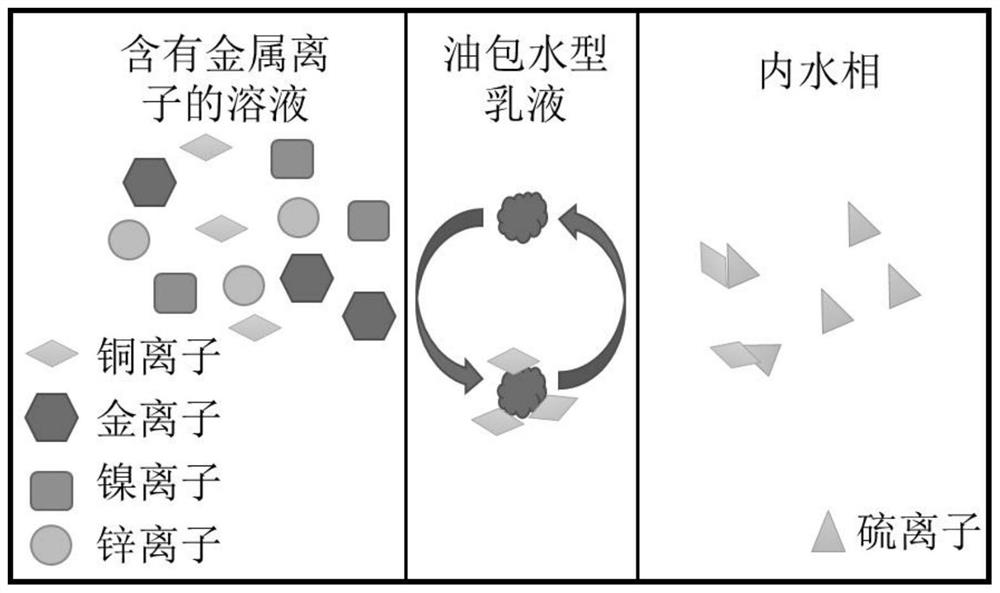

Water-in-oil emulsion as well as preparation method and application thereof

A water-in-oil type and emulsion technology, which is applied in the direction of improving process efficiency and can solve problems such as inability to achieve directional metal recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The present invention also provides a preparation method of the water-in-oil emulsion described in the above technical solution, comprising the following steps:

[0047] The kerosene, the surfactant, the carrier and the inner aqueous phase solution are mixed to obtain the water-in-oil emulsion. In the present invention, the mixing is preferably carried out under stirring conditions; the stirring speed is preferably 2500-3500rpm, more preferably 2600-3300rpm, more preferably 2800-3000rpm; the time is preferably 8-12min, more preferably 9 to 11 minutes, more preferably 10 minutes.

[0048] In the present invention, the mixing preferably includes the following steps: premixing the kerosene, the surfactant and the carrier, and remixing the obtained premixed material with the internal aqueous phase solution.

[0049] In the present invention, the premixing is preferably carried out under stirring conditions; the stirring speed is preferably 300-600rpm, more preferably 350-5...

Embodiment 1

[0077] Take 9mL Span 85, 7mL isoamyl acetate, 44mL kerosene and 60mL sodium sulfide solution with a concentration of 0.2mol / L, and stir at 3000rpm for 10min to obtain a water-in-oil emulsion;

[0078] Mix 2g of the broken circuit board, 20mL of concentrated nitric acid and 20mL of hydrogen peroxide. After the heat release, stir in a water bath at 50°C at a stirring speed of 300rpm for 2h to carry out the digestion reaction. After the reaction is completed, let it stand for cooling and separate After obtaining the supernatant, adjust the pH value of the supernatant to 5 to obtain a solution containing metal ions;

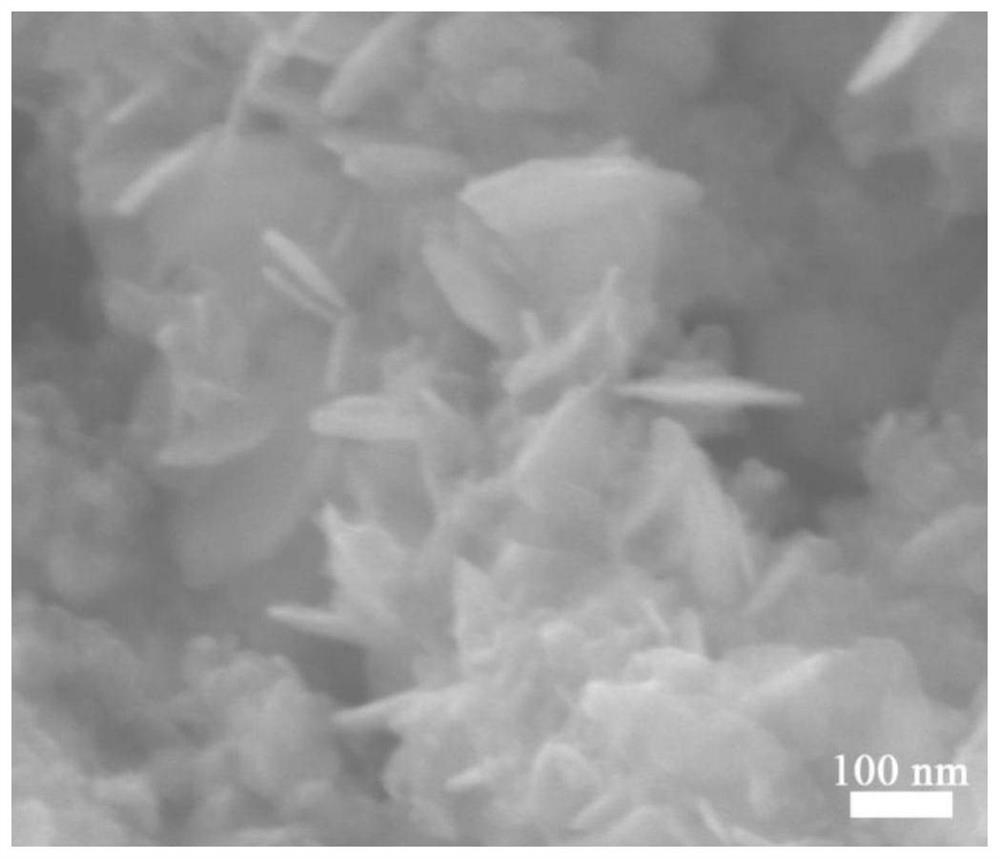

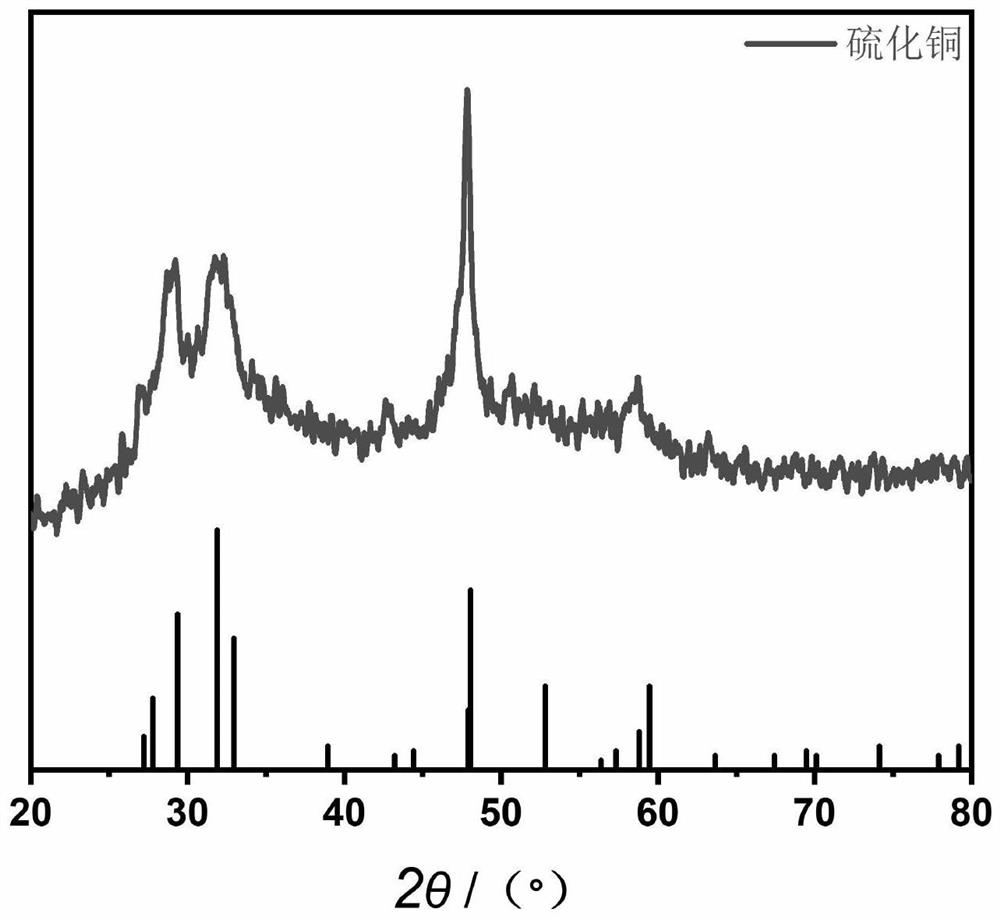

[0079] Take 30mL of water-in-oil emulsion and 50mL of a solution containing metal ions with a mass concentration of 2g / L, stir at 600rpm for 15min; let stand for 2h to separate the layers, and then mix the separated organic phase with 50mL of water , centrifuged at a speed of 6000rpm for 2 minutes, repeated centrifugation twice, and dried the solid obtained by centri...

Embodiment 2

[0081] Take 6mL Span 85, 6mL alkylphosphonic acid, 6mL liquid paraffin, 42mL kerosene and 60mL sodium sulfide solution with a concentration of 0.2mol / L, and stir for 10min at a speed of 3500rpm to obtain a water-in-oil emulsion;

[0082] Mix 2g of the broken circuit board, 20mL of concentrated nitric acid and 20mL of hydrogen peroxide. After the heat release, stir in a water bath at 50°C at a stirring speed of 300rpm for 2h to carry out the digestion reaction. After the reaction is completed, let it stand for cooling and separate After obtaining the supernatant, adjust the pH value of the supernatant to 5 to obtain a solution containing metal ions;

[0083] Take 30mL of water-in-oil emulsion and 60mL of a solution containing metal ions with a mass concentration of 1.5g / L, stir at 600rpm for 15min; let stand for 2h to separate the layers, and then mix the separated organic phase with 50mL of ethanol Finally, centrifugation was carried out at a rotating speed of 6000 rpm for 2 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com