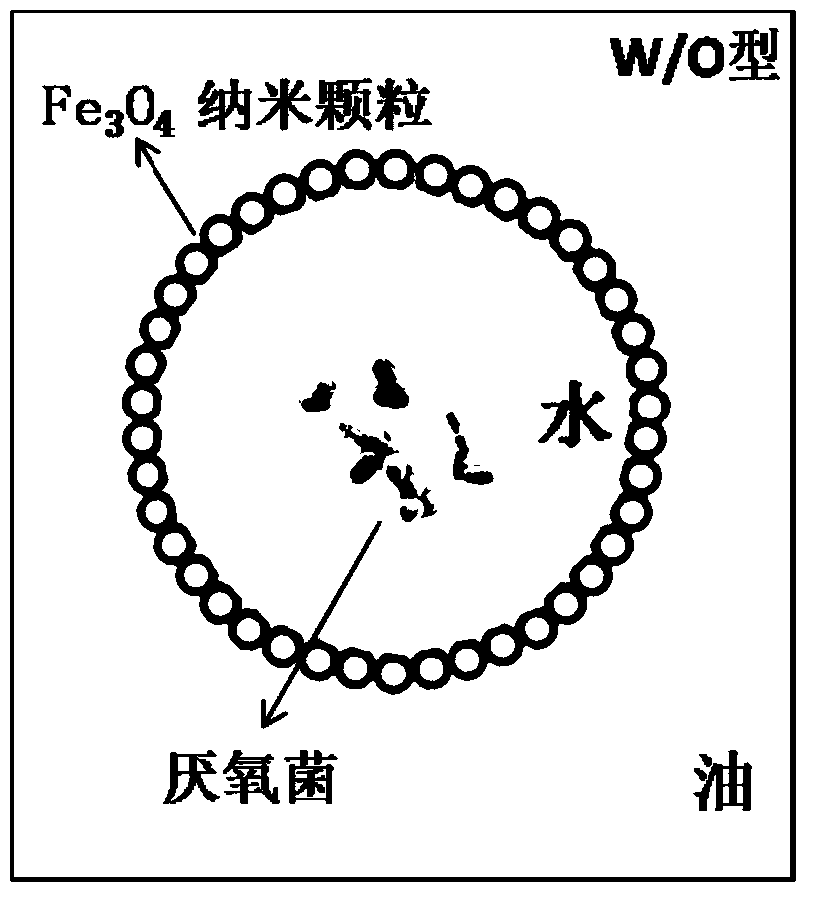

A method for fermenting and cultivating anaerobic bacteria based on magnetic response pickering emulsion

A fermentation culture, magnetic response technology, applied in biochemical equipment and methods, microorganisms, microorganisms, etc., can solve the problems of high input cost, unfavorable small amount of anaerobic bacteria culture, bacterial transfer and other problems, and achieves strong practicability and long system. time-steady effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] According to the growth habit of lactic acid bacteria, the culture medium was prepared with 0.5wt% peptone, 0.5wt% glucose, 0.5wt% NaCl and 98.5wt% water (mass percentage) as raw materials and sterilized at 121° C. for 20 minutes. Inject 1mL of the original strain into 50mL of the sterilized culture medium, and mix well to form a lactic acid bacteria liquid for use.

[0023] Prepare 60 mL of ethanol / water solution with a volume ratio of 1:1, and weigh 1 g of commercially available Fe 3 o 4 Nanoparticles were added to the above ethanol / water solution, and ultrasonically treated at 25° C. and 40 KHz for 20 minutes. Fe to be ultrasonically dispersed 3 o 4 After the nanoparticles had naturally settled, the supernatant was removed. Add ethanol / water solution and repeat the above-mentioned washing operation 3 times, after the washing is completed, the Fe 3 o 4 Add 30mL of absolute ethanol to the nanoparticle precipitation, and disperse with electric stirring for 30 minu...

Embodiment 2

[0026] Embodiment two: in (a) step, Fe 3 o 4Nanoparticle precipitation: dehydrated alcohol: dodecyltrichlorosilane: water=1:24:1:30 (mass ratio), in (b) step, bacteria liquid: n-octane=8:5 (mass ratio) Other production conditions are as embodiment one.

Embodiment 3

[0027] Embodiment three: in (a) step, Fe 3 o 4 Nanoparticle precipitation: dehydrated alcohol: octadecyltrichlorosilane: water=1:24:2:30 (mass ratio), in (b) step, bacterial liquid: white oil=8:11 (mass ratio) other The production conditions are as in Example 1.

[0028] It can be seen from the above examples that the anaerobic bacteria fermentation system based on the magnetic response Pickering emulsion of the present invention can realize the cultivation and directional transfer of anaerobic bacteria, and has broad application prospects.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com