Corrosion monitoring system and method based on two-dimensional flexible area array piezoelectric ultrasound

A piezoelectric ultrasonic and corrosion monitoring technology, applied in the pipeline system, using ultrasonic/sonic/infrasonic waves, using sound waves/ultrasonic/infrasonic waves to analyze solids, etc., can solve the problems of inaccurate pipeline monitoring, high risk and difficulty of manual detection, etc. , to achieve intuitive monitoring results, reduce labor costs, and accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

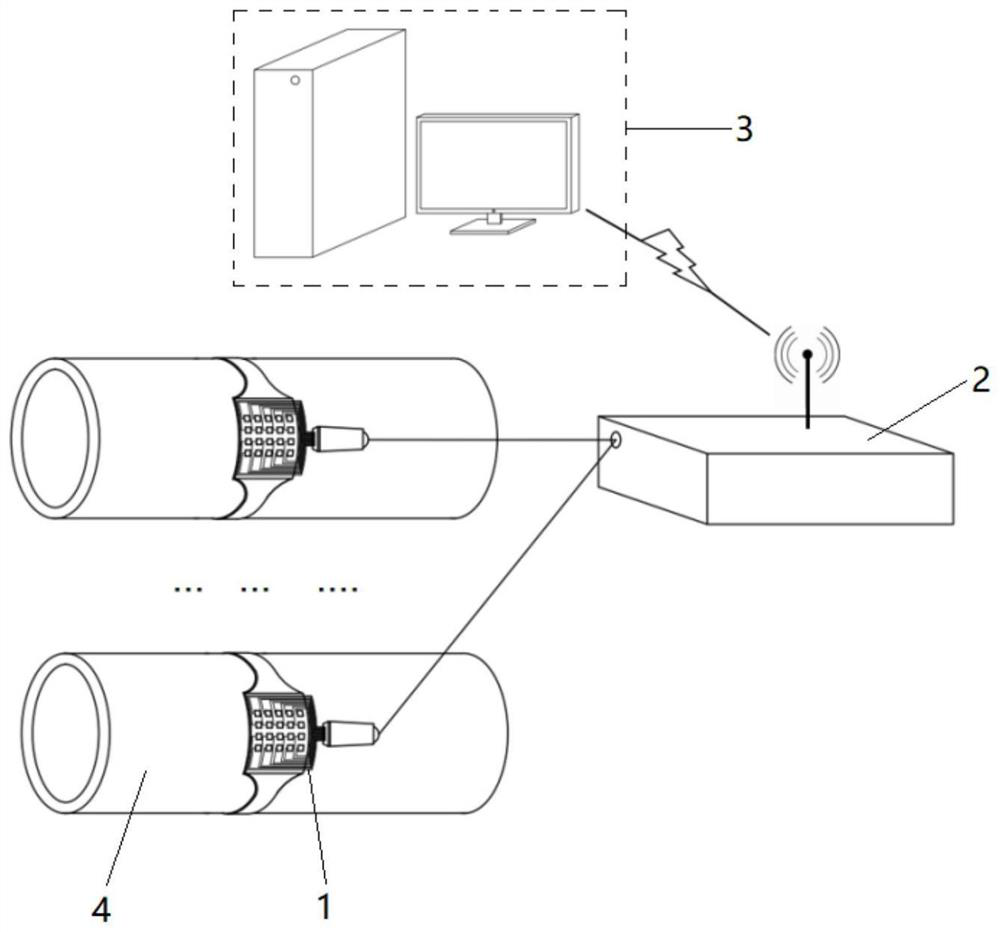

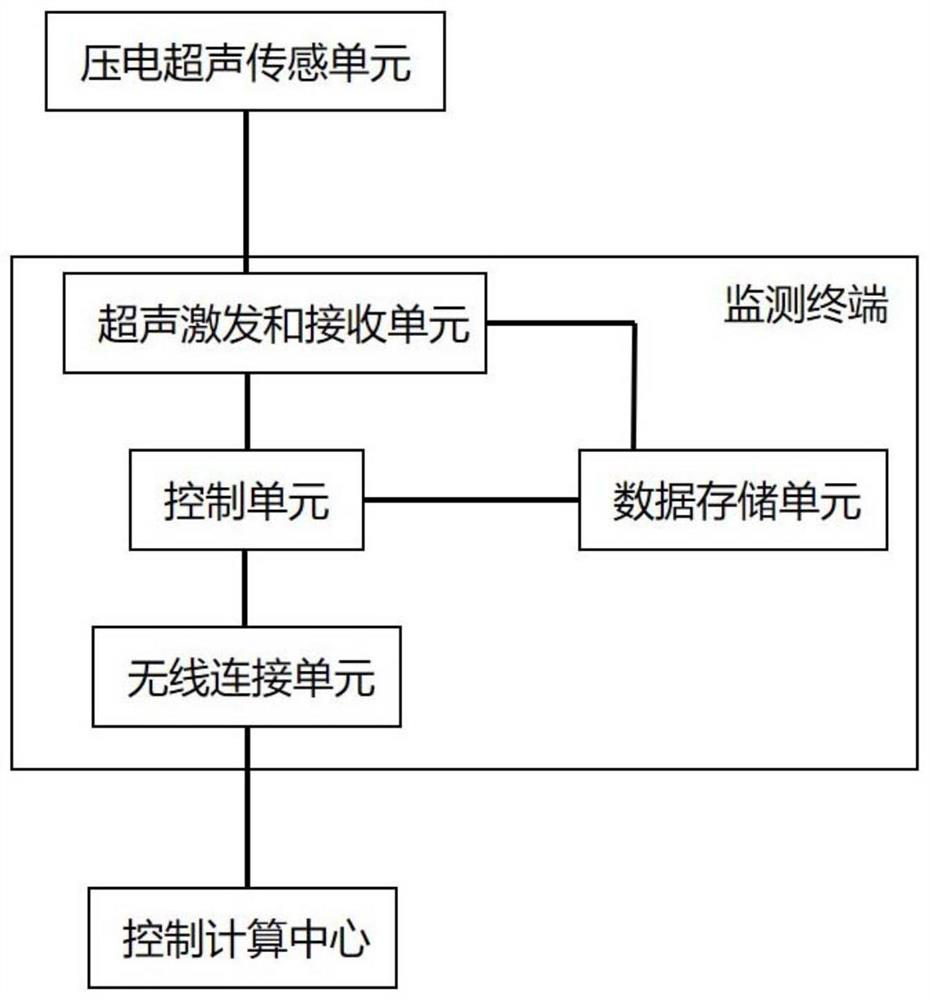

[0051] A corrosion monitoring system based on two-dimensional flexible area piezoelectric ultrasonic in this specific embodiment, this system is preferably used for pipeline corrosion monitoring, the system includes: piezoelectric ultrasonic sensing unit 1, monitoring terminal 2 and control computing center 3 , the connection method is as figure 1 As shown, the piezoelectric ultrasonic sensing unit 1 is connected to the monitoring terminal 2, and the control computing center 3 is connected to the monitoring terminal 2. A preferred embodiment adopted by the present invention is that the control computing center 3 and the monitoring terminal 2 are connected wirelessly. , 4G network is the most common way of implementation.

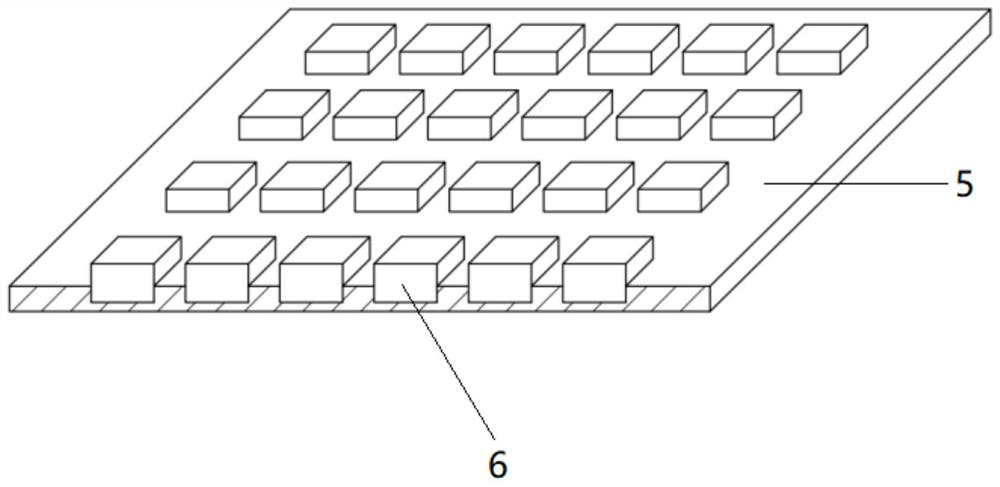

[0052] The piezoelectric ultrasonic sensing unit 1 is used to collect pipeline data, and adopts a two-dimensional flexible area piezoelectric ultrasonic sensor 11, which is directly coupled with the surface of the pipeline; image 3 As shown, the two-dimens...

Embodiment 2

[0076] On the basis of Example 1, the pipeline in the actual project may be a curved pipeline 12 or a straight pipeline 4, Figure 6 and Figure 7 The installation of the two-dimensional flexible area piezoelectric ultrasonic sensor 11 of the straight pipe and its preloaded structure is shown, such as Figure 6 As shown, the two-dimensional flexible area array piezoelectric ultrasonic sensor 11 in this embodiment adopts a full-circumferential flexible area array sensor 15, which is installed on the straight pipe 12 at 360 degrees in the circumferential direction. Figure 6 It is a schematic diagram of the details of the preload structure of the adaptive straight-tube flexible airbag, Figure 7 It is a schematic diagram of installation of the self-adaptive straight tube flexible airbag pretensioning structure of the present invention.

Embodiment 3

[0078] The monitoring system and monitoring method of the present invention can not only be used for pipeline monitoring, but also can be used for metal loss monitoring in other working conditions, such as the erosion monitoring of manifolds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com