Diaphragm valve

A diaphragm valve and diaphragm technology, which is applied in the direction of diaphragm valves, diaphragms, valve devices, etc., can solve the problems of inability to cope with changes in valve seat thickness, inability to cope with high temperature state specifications, thickness changes, etc., to reduce unevenness and prevent valve seat leakage , the effect of reducing the amount of adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

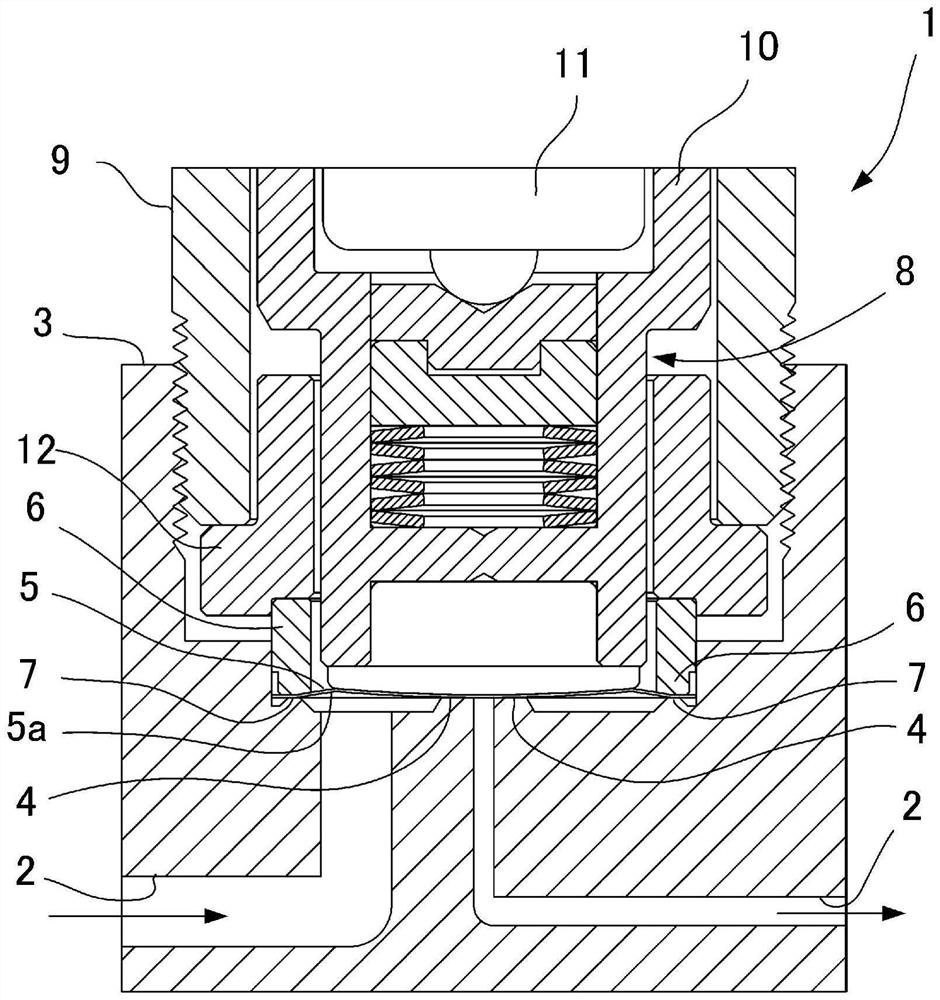

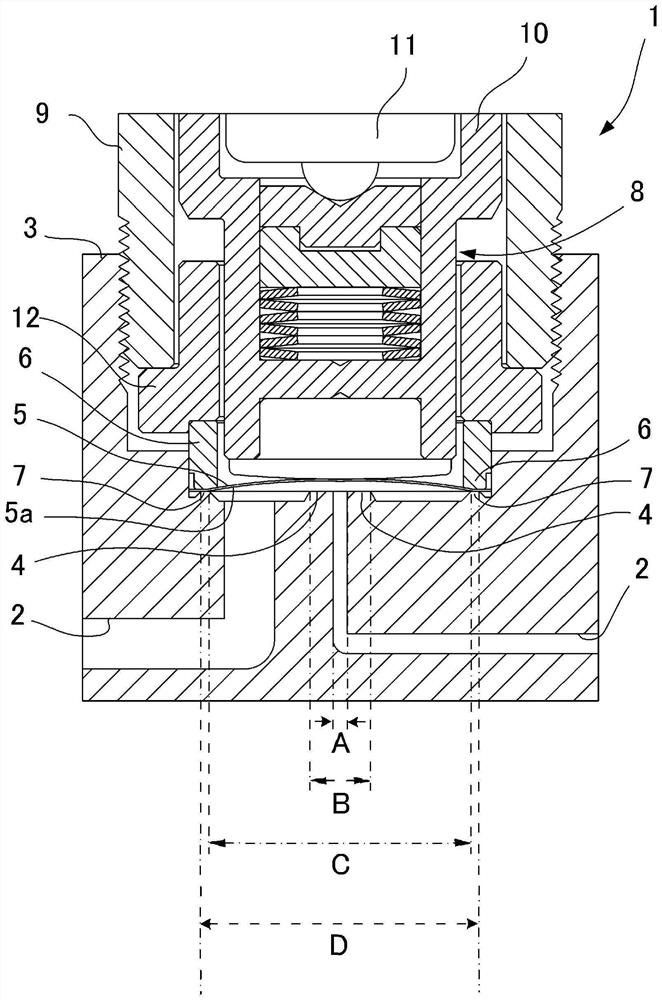

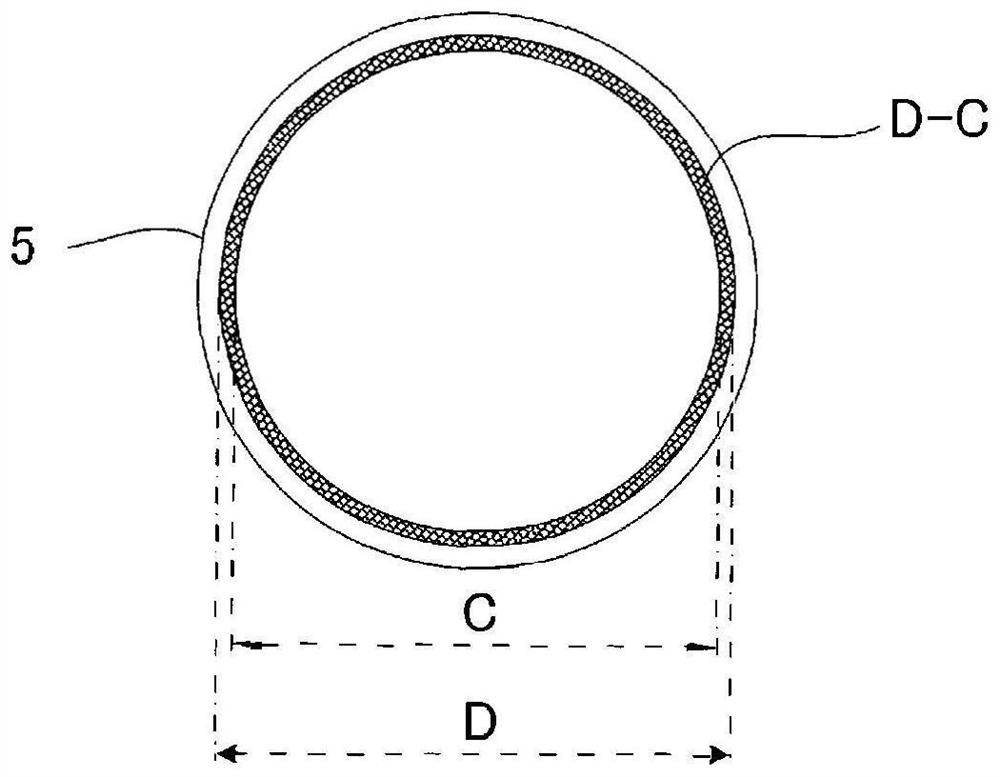

[0038] Regarding an embodiment of the present invention, refer to Figure 1 to Figure 8 while explaining. In addition, in all drawings, the same code|symbol is attached|subjected to the same or similar component.

[0039] refer to figure 1 as well as figure 2 The diaphragm valve 1 includes: a valve body 3 formed with a flow path 2; a valve seat 4 formed on the flow path 2; a metal diaphragm 5 that opens and closes the flow path 2 by contacting or moving away from the valve seat 4; Fixing the metal diaphragm 5 to a pair of clamping portions 6, 7 of the valve body 3 by clamping the peripheral edge portions of both sides of the metal diaphragm 5 respectively; and making the metal diaphragm 5 contact the valve seat 4 or Remote actuator 8.

[0040] The valve body 3 can be formed of metal such as stainless steel, for example. In addition, both the clamping parts 6 and 7 can be formed of metal (including alloy). In the example shown in the drawings, the clamping portion 7 abu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com