Two-dimensional MXene-based oil-water separation membrane and preparation method thereof

An oil-water separation membrane and base oil technology, applied in the field of materials, can solve the problems of human health and surrounding environment threats, poor anti-pollution performance, easy powder agglomeration, etc., to achieve excellent anti-pollution ability and reusability, and improved anti-pollution ability. , to ensure the effect of interception efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

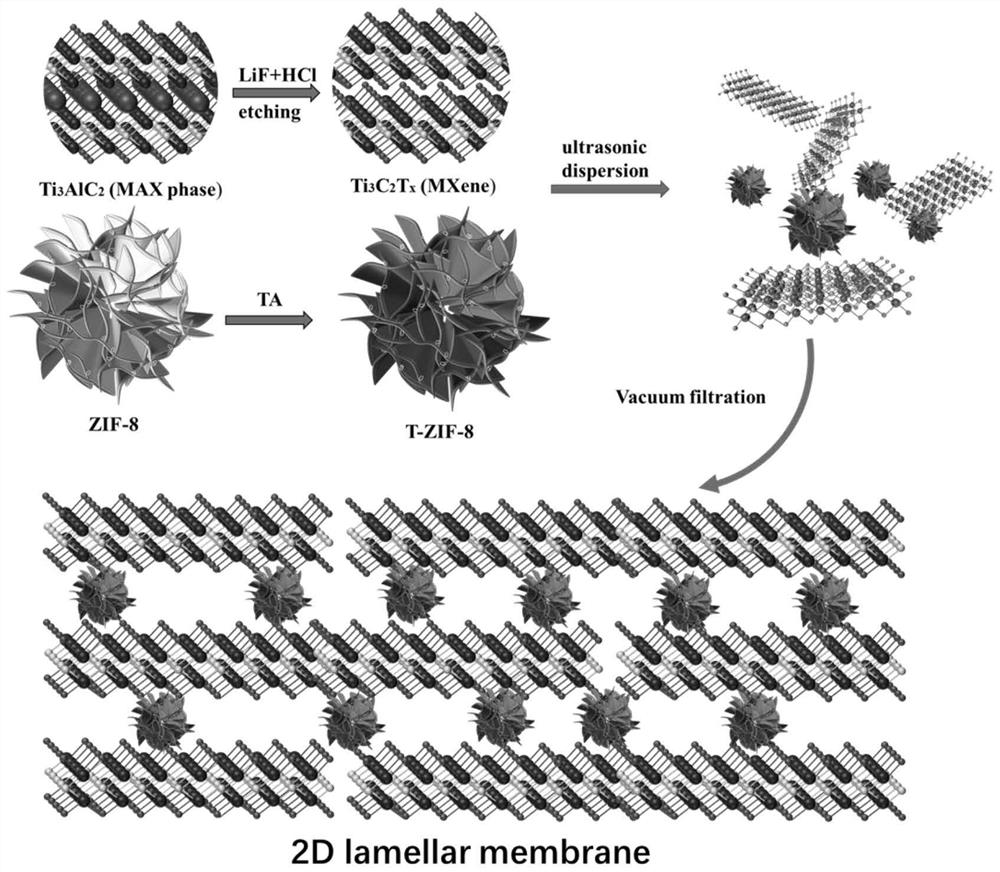

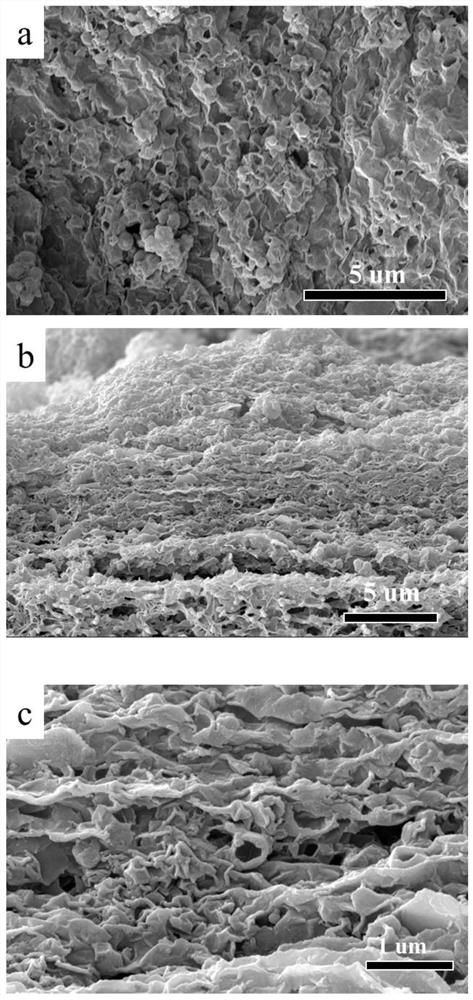

[0032] A preparation method of a two-dimensional MXene-based oil-water separation membrane, comprising:

[0033] (1) Preparation of MXene:

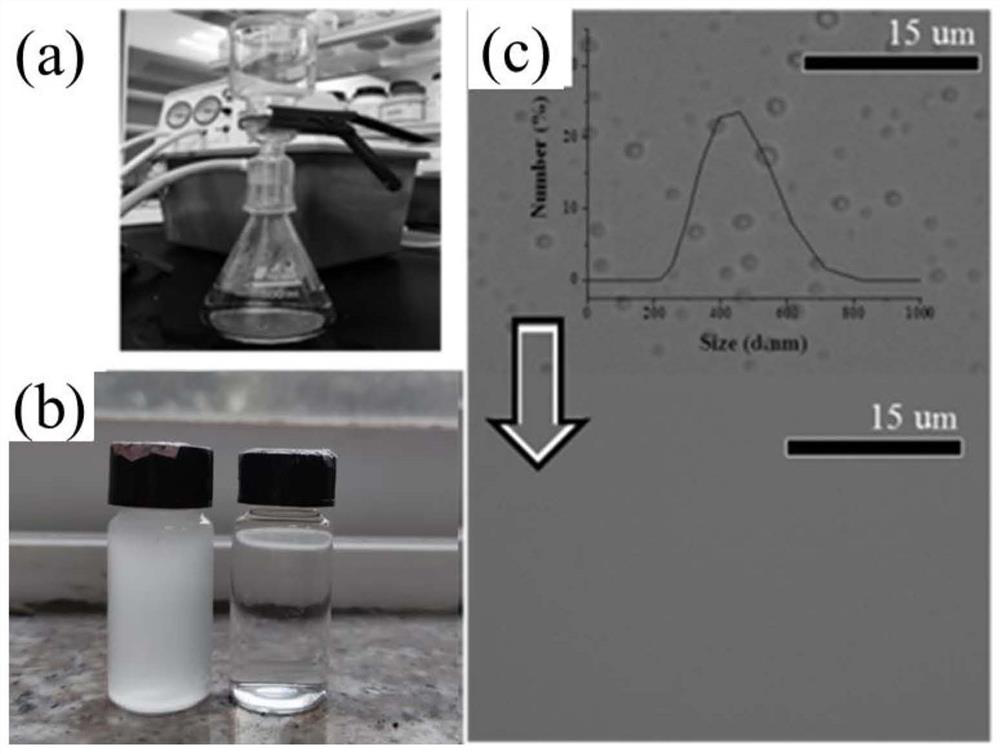

[0034] Add 0.5 g LiF and 20 mL 9m HCl in a beaker, then mix slowly and stir for 0.5 h. Subsequently, 0.5 g MAX was added to the above mixed solution, and stirring was continued at 30 °C for 24 h. After the reaction, the collected precipitate was washed several times with deionized water, and centrifuged repeatedly (3500 rpm, 10 min) to remove residual acid in the precipitate until the pH value of the solution was about 6.0. The sample was dispersed in 200 mL deionized water, treated with an ultrasonic device at room temperature, and stirred continuously for 6 h. To prevent the oxidation of MXene nanosheets, the whole operation was performed under nitrogen. Afterwards, the suspension obtained by sonication was centrifuged (8000 rpm, 30 min) to remove unpeeled flakes. Finally, the supernatant was collected and freeze-dried to obtain the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com