Preparation equipment and preparation method of binder asphalt

A technology for binder asphalt and equipment, which is applied to the preparation equipment and field of binder asphalt, can solve problems such as inability to handle and affect the final quality of modified asphalt, and achieve the effect of improving the final quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

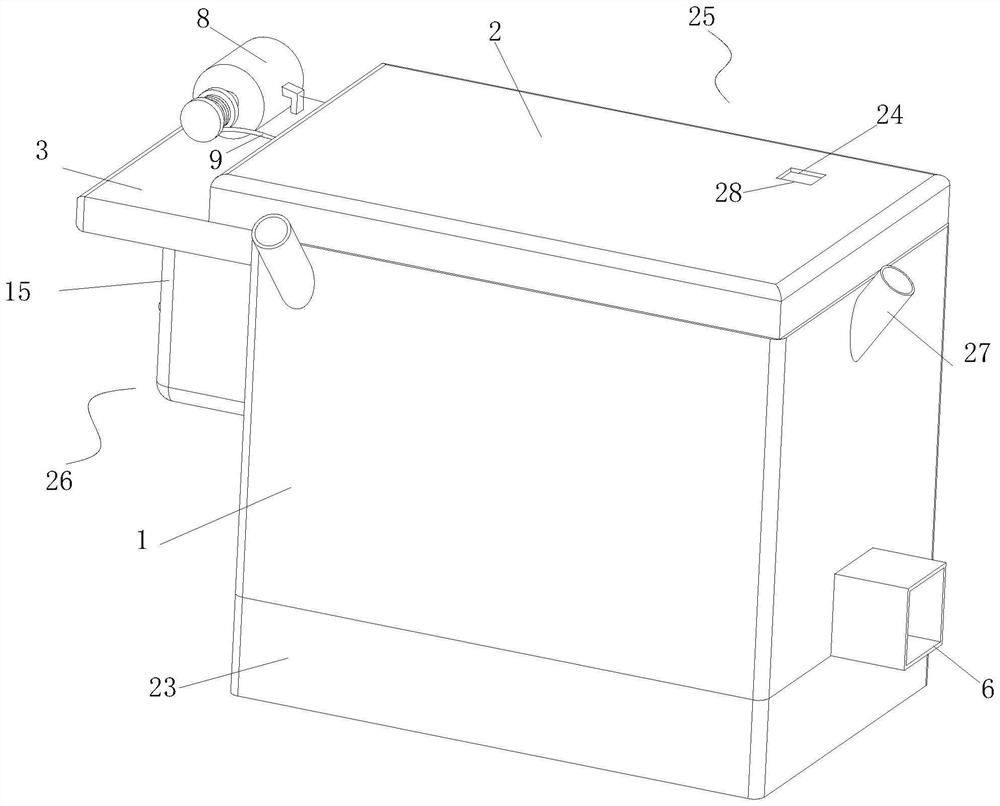

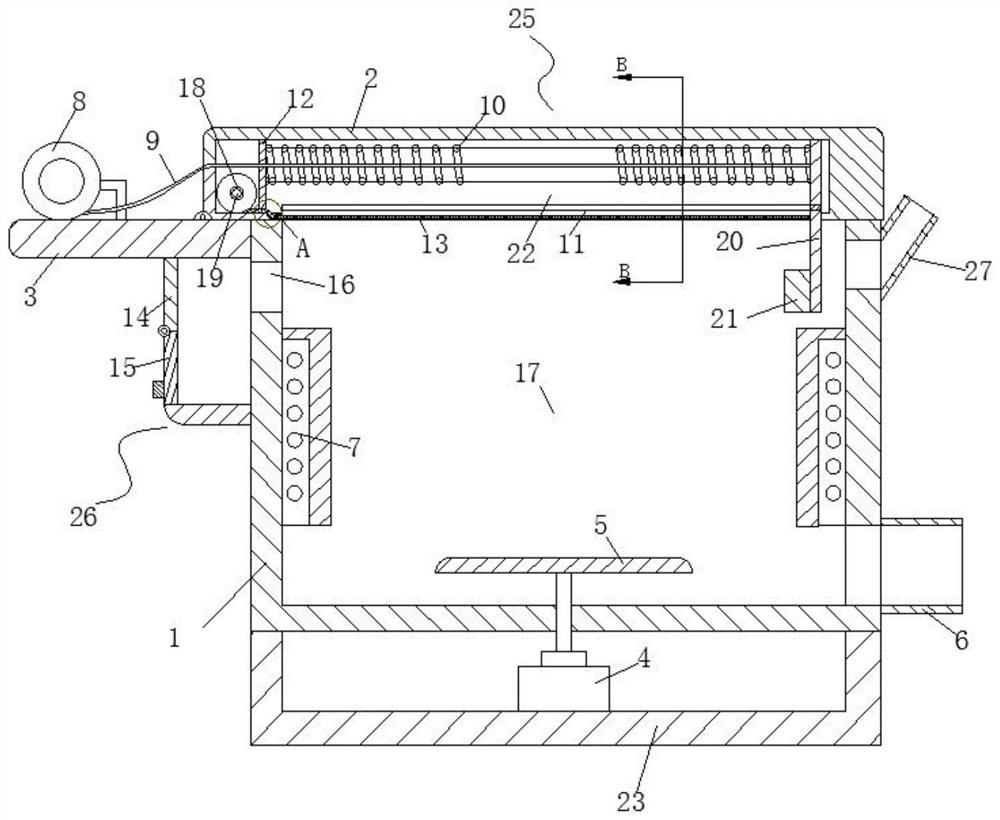

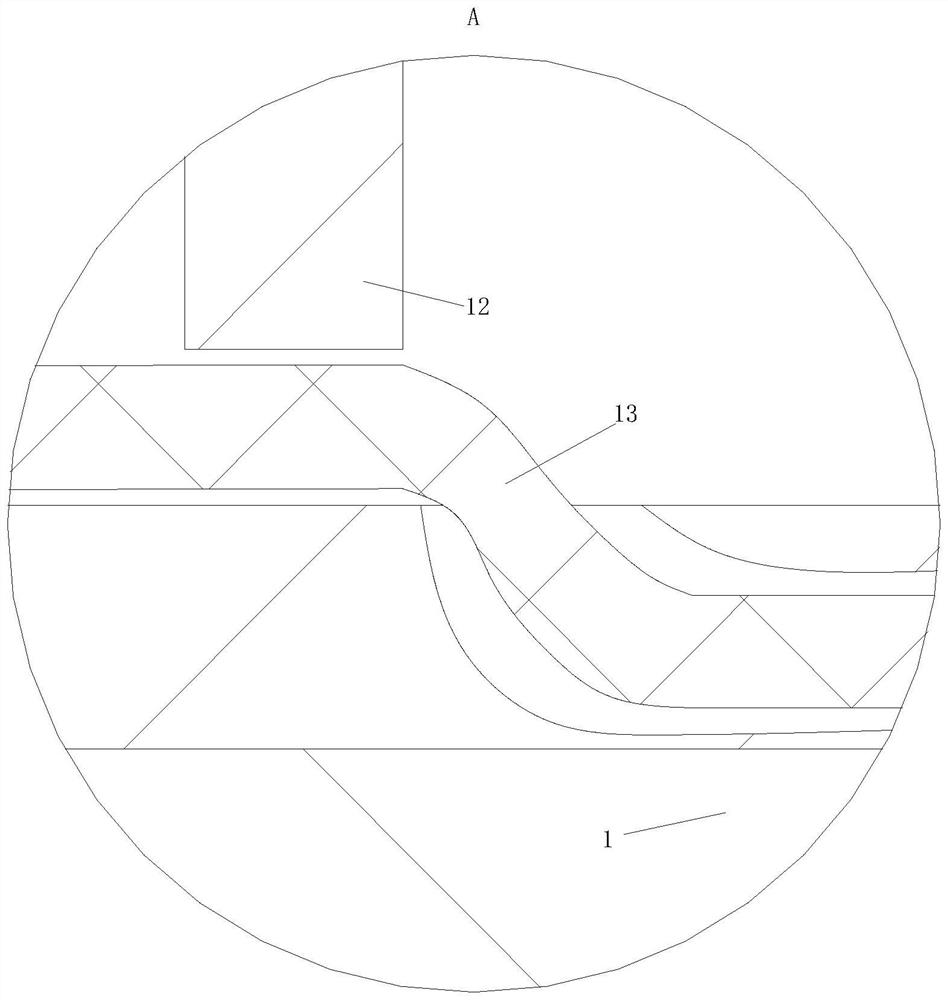

[0043] As an embodiment of the present invention, the defoaming unit 25 includes a motor 8, a traction rope 9, a spring 10, a T-shaped slot 11, a scraper 20 and a baffle 12; the motor 8 is fixedly connected to the fixed plate 3; The output shaft of the motor 8 is fixedly connected and is wound with a traction rope 9; the other end of the traction rope 9 passes through the box cover 2 and the baffle plate 12 and is fixedly connected to the scraper 20; the inside of the box cover 2 is provided with a cavity 22; a baffle plate 12 is provided near the motor 8 in the cavity 22; the baffle plate 12 is fixedly connected with the cavity wall of the cavity 22; the traction rope 9 is set between the scraper 20 and the baffle plate 12 There is a spring 10; the two ends of the spring 10 are fixedly connected with the baffle plate 12 and the scraper 20 respectively; the side of the box cover 2 close to the box body 1 is provided with a T-shaped groove 11; the T-shaped groove 11 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com