Dispersion-strengthened high-entropy dodecaboride-based composite material and preparation method thereof

A composite material and dispersion strengthening technology, which is applied in the field of dispersion strengthened high-entropy dodecaboride-based composite materials and its preparation, can solve the problems of insufficient hardness of high-entropy ceramics, achieve the solution of insufficient hardness, and realize the improvement of material hardness and hardness value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

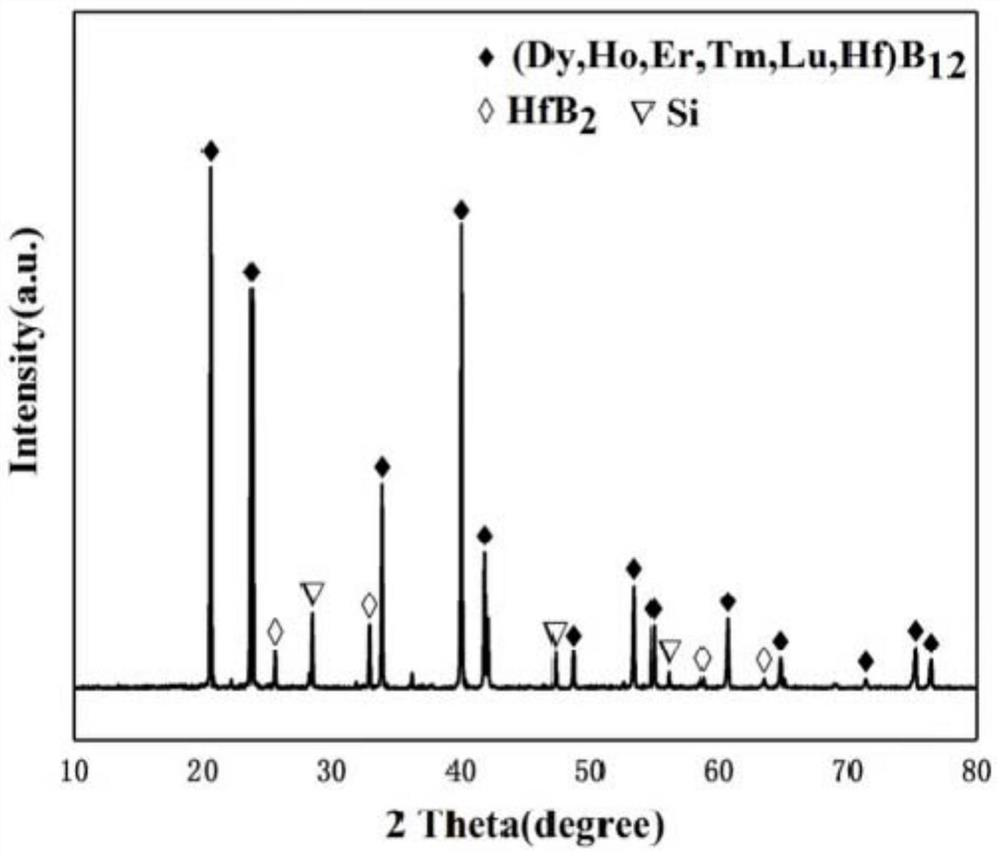

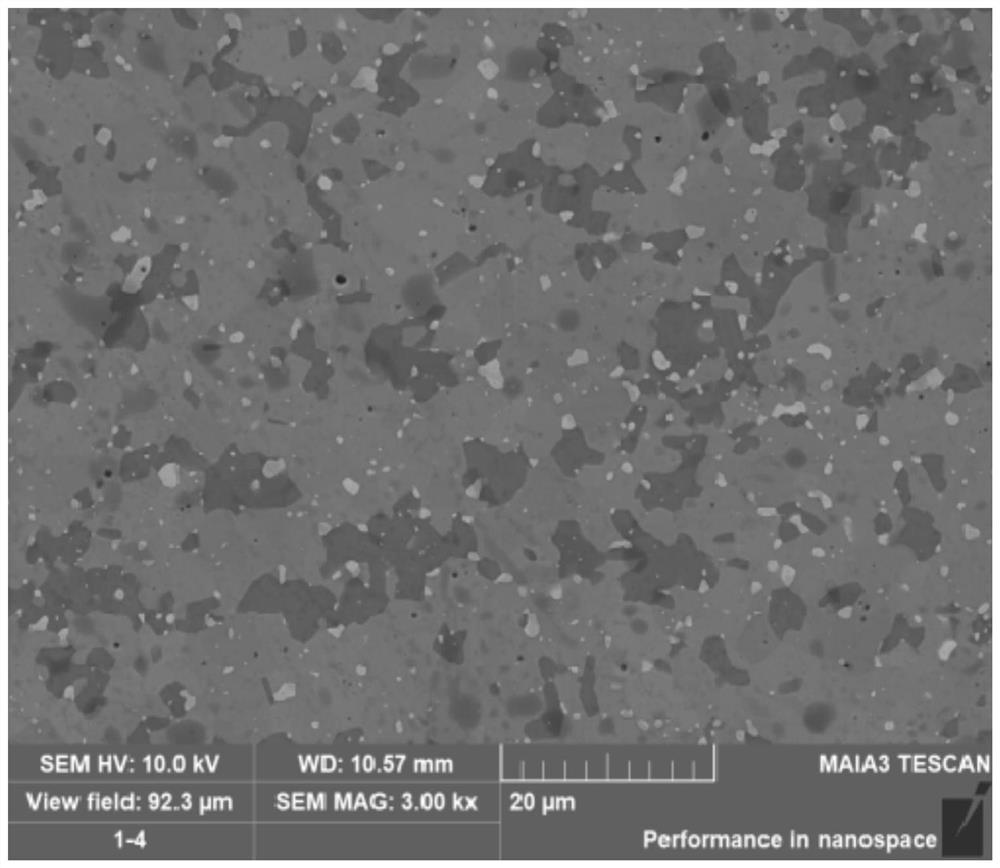

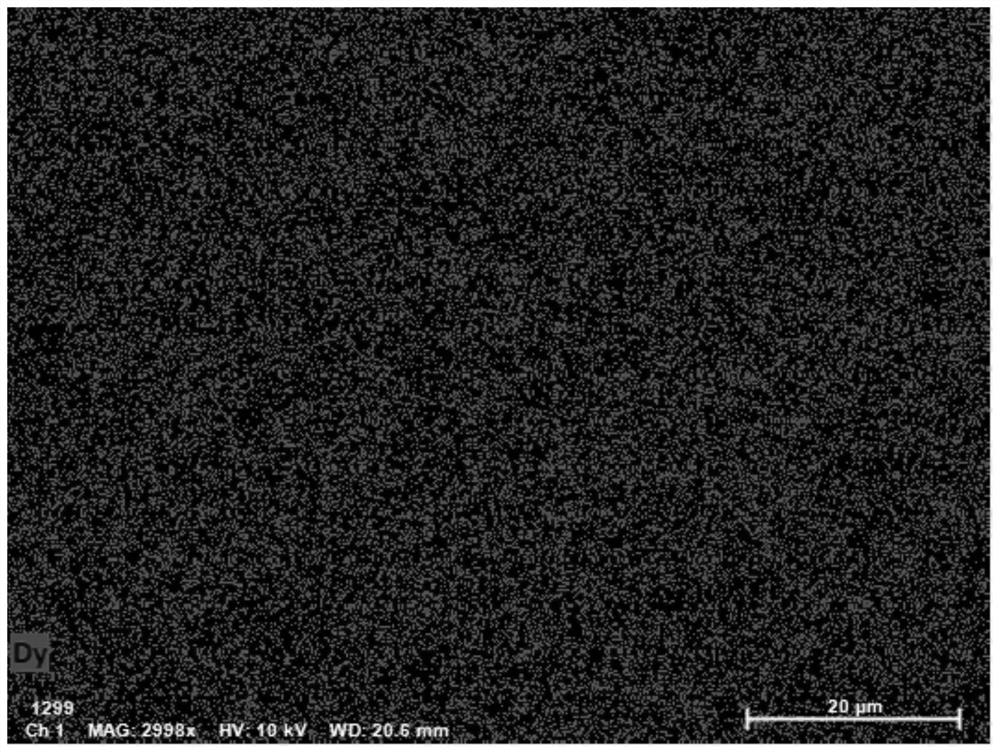

Embodiment 1

[0022] The preparation composition is 90% (Dy 1 / 6 Ho 1 / 6 Er 1 / 6 T m 1 / 6 Lu 1 / 6 f 1 / 6 )B 12 with 10% HfB 2 The composite material comprises the following steps:

[0023] (1) Choose Dy with a purity ≥ 99% 2 o 3 、Ho 2 o 3 、Er 2 o 3 、Tm 2 o 3 、Lu 2 o 3 , HfO 2 Metal oxides and amorphous boron powder with a purity ≥ 95% are used as raw materials. The particle size of the raw materials is ≥ 60 mesh, and the proportion (molar ratio) is Dy 2 o 3 :Ho 2 o 3 :Er 2 o 3 :Tm 2 o 3 :Lu 2 o 3 :HfO 2 :B=3:3:3:3:3:10:384, that is, the boron excess is 10%. The raw materials were mixed according to the above ratio and placed in a ball mill tank, with ethanol as solvent, ZrO 2 The ball is a grinding bead, which is mixed for 24 hours at a speed of 120 revs / min on a ball pot grinder to obtain a uniform mixed solution;

[0024] (2) Pour the mixed solution obtained in step (1) into a flask, evaporate to dryness through a rotary evaporator, and grind the powder with a mort...

Embodiment 2

[0029] The preparation composition is 90% (Dy 0.18 Ho 0.18 Er 0.18 T m 0.18 Lu 0.18 f 0.1 )B 12 with 10% HfB 2 Composite materials, including the following steps:

[0030] (1) Choose Dy with a purity ≥ 99% 2 o 3 、Ho 2 o 3 、Er 2 o 3 、Tm 2 o 3 、Lu 2 o 3 , HfO 2 Metal oxides and amorphous boron powder with a purity ≥ 95% are used as raw materials. The particle size of the raw materials is ≥ 60 mesh, and the proportion (molar ratio) is Dy 2 o 3 :Ho 2 o 3 :Er 2 o 3 :Tm 2 o 3 :Lu 2 o 3 :HfO 2 :B=81:81:81:81:81:190:12100, that is, 10% excess boron. The raw materials were mixed according to the above ratio and placed in a ball mill tank, with ethanol as solvent, ZrO 2 The ball is a grinding bead, which is mixed for 24 hours at a speed of 120 revs / min on a ball tank grinder to obtain a uniform mixed solution;

[0031] (2) Pour the mixed solution obtained in step (1) into a flask, evaporate to dryness through a rotary evaporator, and pass the gained sample ...

Embodiment 3

[0036] The preparation composition is 90% (Dy 0.16 Ho 0.16 Er 0.16 T m 0.16 Lu 0.16 f 0.2 )B 12 with 10% HfB 2 Composite materials, including the following steps:

[0037] (1) Choose Dy with a purity ≥ 99% 2 o 3 、Ho 2 o 3 、Er 2 o 3 、Tm 2 o 3 、Lu 2 o 3 , HfO 2 and other metal oxides and amorphous boron powder with a purity ≥ 95% are used as raw materials, and the particle size of the raw materials is ≥ 60 mesh, and the proportion (molar ratio) is Dy 2 o 3 :Ho 2 o 3 :Er 2 o 3 :Tm 2 o 3 :Lu 2 o 3 :HfO 2 :B=18:18:18:18:18:70:3025, that is, 10% excess boron. The raw materials are mixed according to the above ratio and placed in a ball mill tank, with ethanol as a solvent, ZrO 2 The balls are grinding beads, which are mixed for 24 hours at a speed of 120 rpm on a ball tank grinder to obtain a uniform mixed solution;

[0038] (2) Pour the mixed solution obtained in step (1) into a flask, evaporate to dryness through a rotary evaporator, and pass the gain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com