Ultrahigh-strength low-dynamic-static-stiffness-ratio polyurethane microporous elastic backing plate and preparation method thereof

A microcellular elasticity and ultra-high strength technology, applied in the field of microcellular polyurethane, can solve problems such as increased stiffness, low mechanical properties, and inability to meet vibration reduction requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

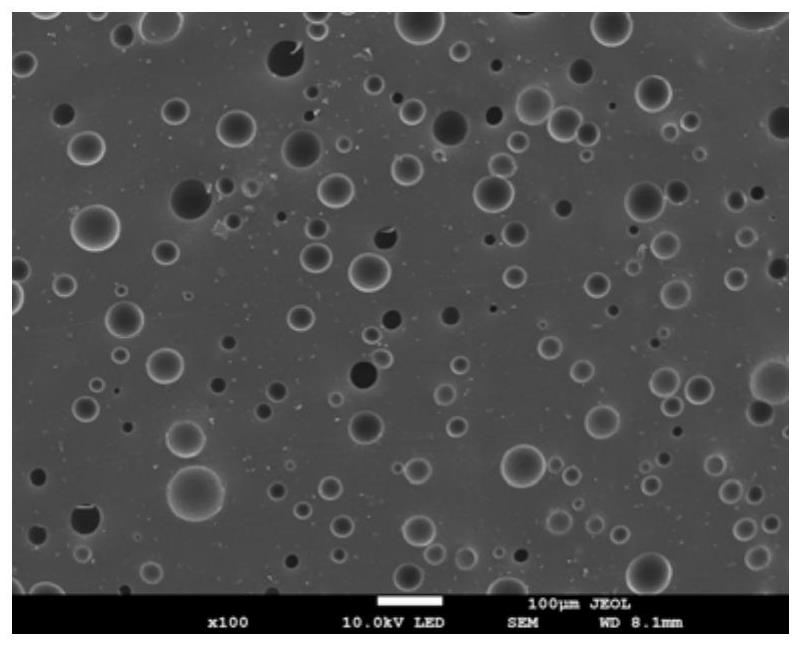

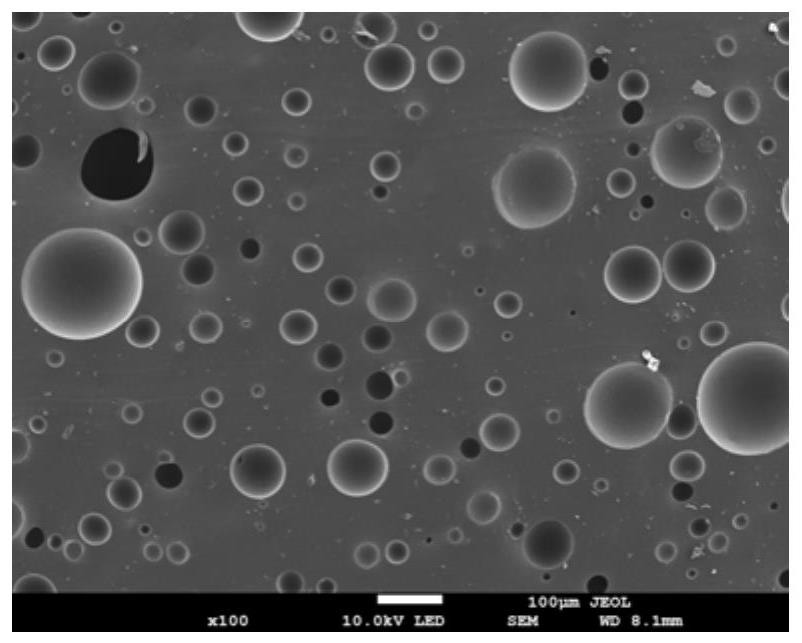

Image

Examples

Embodiment 1

[0034] (1) Taking the total mass of raw materials for preparing the A component as 100%, each raw material composition and its mass fraction are as follows:

[0035]

[0036] The diameter of carbon nanotubes is 10-20nm, and the length is 5-15μm;

[0037] Mix the above raw materials evenly to obtain component A;

[0038] Based on the total mass of the raw materials for preparing the B component as 100%, the raw material components and their mass fractions are as follows:

[0039] MDI 50%;

[0040] PTMEG1000 50%;

[0041] After mixing the above raw materials, under a nitrogen protective atmosphere, stir and react at 85°C for 4 hours to obtain component B with an -NCO value of 12.56;

[0042] (2) According to the molar ratio of active -H in component A and -NCO group in component B being 1:1, component A preheated to 35°C and component B preheated to 45°C were double- After the components are mixed evenly by the polyurethane pouring machine, they are poured into a lockable...

Embodiment 2

[0045] (1) Taking the total mass of raw materials for preparing the A component as 100%, each raw material composition and its mass fraction are as follows:

[0046]

[0047]

[0048] The diameter of carbon nanotubes is 10-20nm, and the length is 5-15μm;

[0049] Mix the above raw materials evenly to obtain component A;

[0050] Based on the total mass of the raw materials for preparing the B component as 100%, the raw material components and their mass fractions are as follows:

[0051] MDI 50%;

[0052] PTMEG1000 50%;

[0053] After mixing the above raw materials, under a nitrogen protective atmosphere, stir and react at 85°C for 4 hours to obtain component B with an -NCO value of 12.56;

[0054](2) According to the molar ratio of active -H in component A and -NCO group in component B being 1:1, component A preheated to 35°C and component B preheated to 45°C were double- After the components are mixed evenly by the polyurethane pouring machine, they are poured into...

Embodiment 3

[0057] (1) Taking the total mass of raw materials for preparing the A component as 100%, each raw material composition and its mass fraction are as follows:

[0058]

[0059] The diameter of carbon nanotubes is 10-20nm, and the length is 5-15μm;

[0060] Mix the above raw materials evenly to obtain component A;

[0061] Based on the total mass of the raw materials for preparing the B component as 100%, the raw material components and their mass fractions are as follows:

[0062] MDI 50%;

[0063] PTMEG1000 50%;

[0064] After mixing the above raw materials, under a nitrogen protective atmosphere, stir and react at 85°C for 4 hours to obtain component B with an -NCO value of 12.56;

[0065] (2) According to the molar ratio of active -H in component A and -NCO group in component B being 1:1, component A preheated to 35°C and component B preheated to 45°C were double- After the components are mixed evenly by the polyurethane pouring machine, they are poured into a lockable...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com