Acidified soil conditioner and preparation method thereof

A soil conditioner and conditioner technology, applied in the preparation of organic fertilizers, the treatment of invertebrates, agriculture, etc., can solve problems such as soil acidification, reduce diseases, avoid secondary input, and improve the ability to maintain and supply fertilizer. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] An acidifying soil improver, comprising the following components in parts by weight: 70 parts of agar slag, 4 parts of silicon powder, 5 parts of calcium powder, 3 parts of dissociating agent Fe2(SO4)3, and 1 part of conditioning agent hydrochloric acid.

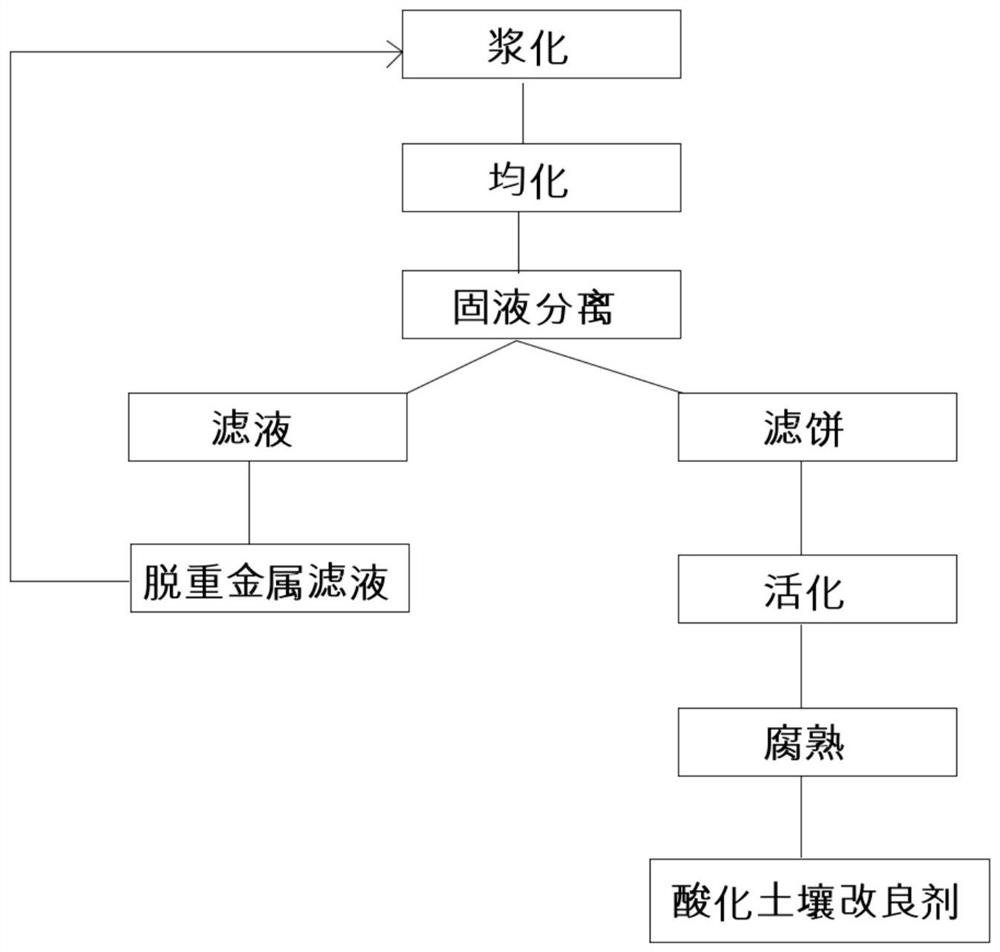

[0037] The preparation method of present embodiment 1 soil conditioner, its technological process is as figure 1 Shown:

[0038] Step 1, pulping: Put the heavy metal removal filtrate by solvent (or use water as the solvent when putting in for the first time) and the dissociating agent of the above-mentioned parts by weight into the slurrying tank in advance, and put the organic waste of the above-mentioned parts by weight into the slurrying tank , the material ratio is 1:1, and stirred evenly, the stirring speed is 50rpm, and the stirring time is 4h, to obtain a slurry;

[0039] Step 2, homogenization: transfer the slurrying liquid to a homogenization tank, put the conditioning agent in the above parts by weight into...

Embodiment 2

[0044] An acidifying soil improver, comprising the following components in parts by weight: 10 parts of agar slag, 45 parts of food slag, 40 parts of beer, 2 parts of silicon powder, 3 parts of calcium powder, and dissociating agent Fe2(SO4)35 2 parts and conditioner hydrochloric acid 2 parts.

[0045] The preparation method of present embodiment 2 soil conditioners:

[0046] Step 1, pulping: Put the heavy metal removal filtrate by solvent (or use water as the solvent when putting in for the first time) and the dissociating agent of the above-mentioned parts by weight into the slurrying tank in advance, and put the organic waste of the above-mentioned parts by weight into the slurrying tank , the material ratio is 1:3, and stirred evenly, the stirring speed is 75rpm, the stirring time is 2h, and the slurry is obtained;

[0047] Step 2, homogenization: transfer the slurrying liquid to a homogenization tank, put the conditioner in the above parts by weight into the homogenizati...

Embodiment 3

[0052] An acidifying soil improver, comprising the following components in parts by weight: 80 parts of food residue, 1 part of silicon powder, 2 parts of calcium powder, 7 parts of dissociating agent Fe(NO3)3, and 3 parts of conditioning agent hydrochloric acid.

[0053] The preparation method of present embodiment 3 soil conditioners:

[0054] Step 1, pulping: Put the heavy metal removal filtrate by solvent (or use water as the solvent when putting in for the first time) and the dissociating agent of the above-mentioned parts by weight into the slurrying tank in advance, and put the organic waste of the above-mentioned parts by weight into the slurrying tank , the material ratio is 1:2, and stirred evenly, the stirring speed is 100rpm, and the stirring time is 1h, to obtain a slurry;

[0055] Step 2, homogenization: transfer the slurrying liquid to a homogenization tank, put the conditioner in the above parts by weight into the homogenization tank, continue stirring, the sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com