Efficient humic acid fertilizer prepared by using concentrated biogas slurry, and application of efficient humic acid fertilizer

A technology of humic acid and concentrated biogas, applied in application, organic fertilizer, fertilization equipment, etc., can solve the problems of secondary pollution, waste of resources, etc., and achieve the effects of increasing production, growing robustly, and improving pore conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

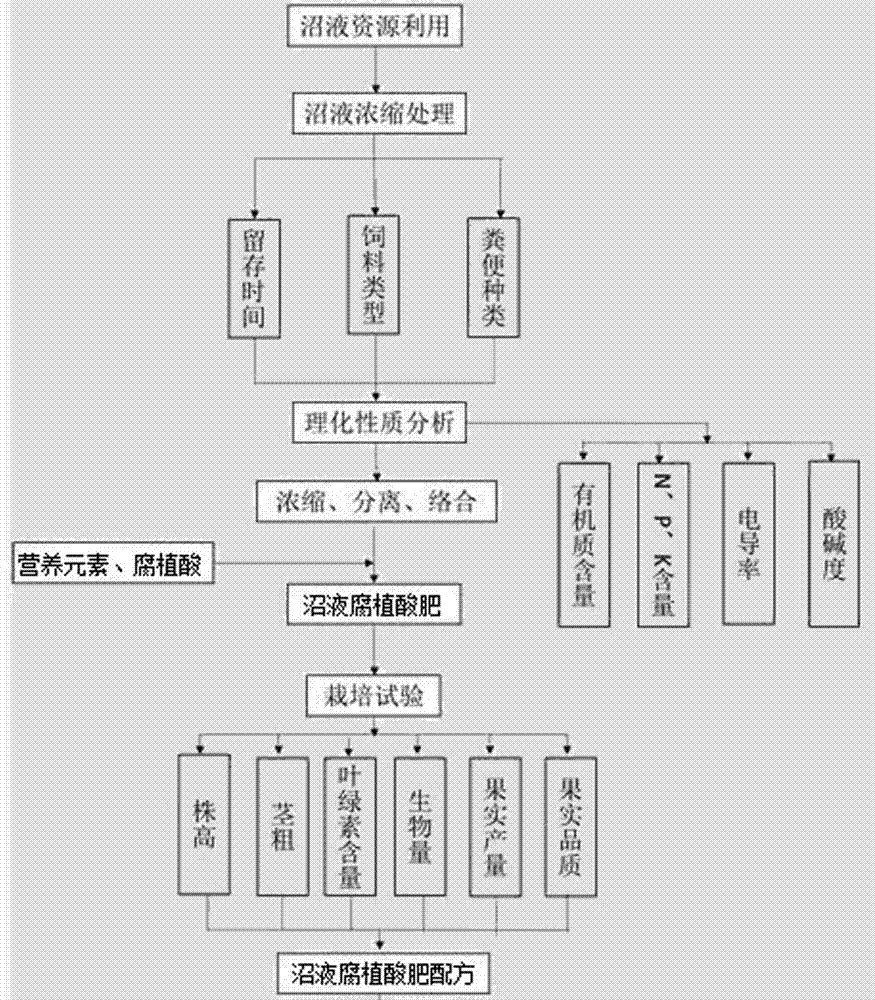

Method used

Image

Examples

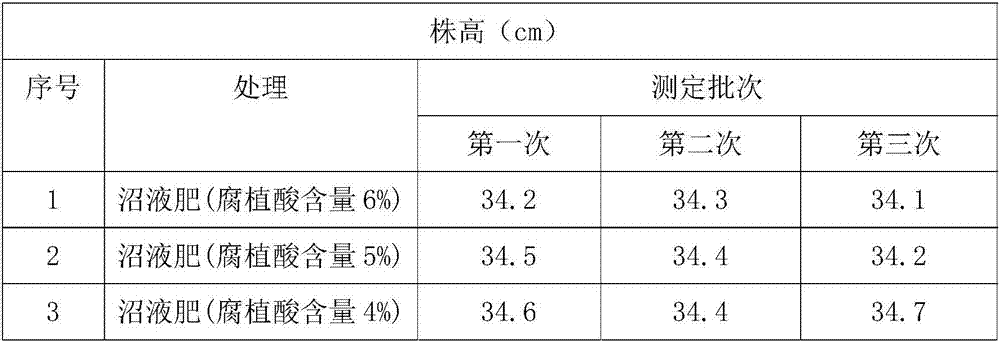

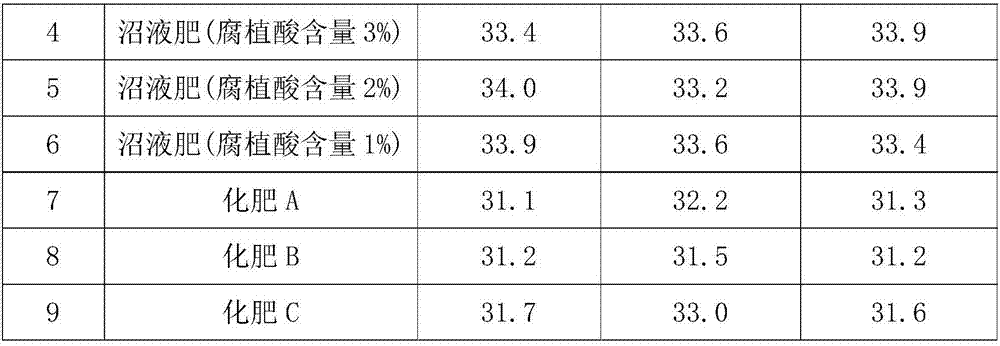

Embodiment 1

[0027] The high-efficiency micro-humic acid fertilizer used in this example is formed by adding humic acid after the biogas slurry is concentrated 10-20 times. In December 2015, a continuous comparison test was started, and different seasons, different raw material ratios, and The nutritional components and physical and chemical properties of the biogas slurry at different fermentation times were determined. The pH value and EC value of high-efficiency humic acid fertilizer were measured by METTLER TOLEDOSevenEasy acidity meter and DDBJ-350 portable conductivity meter; the contents of available nitrogen, phosphorus and potassium were measured by alkaline solution diffusion method, sodium bicarbonate method, ammonium acetate-flame photometer method; the organic matter content was determined by the dilution heat method; the humic acid content was determined by the method described in NY / T 1971. Taking the existing soilless cultivation and chemical fertilizers in the market as th...

Embodiment 2

[0043] The high-efficiency humic acid fertilizer used in this example is formed by adding humic acid after the biogas slurry is concentrated 10-20 times. At the end of February 2016, a continuous comparison test was started, and different seasons, different raw material ratios, and different fermentation times were collected in batches. The biogas slurry was tested for its nutritional components and physical and chemical properties. The pH value and EC value of high-efficiency humic acid fertilizer were measured by METTLER TOLEDO SevenEasy acidity meter and DDBJ-350 portable conductivity meter; the contents of available nitrogen, phosphorus and potassium were measured by alkaline solution diffusion method, sodium bicarbonate method, ammonium acetate-flame photometry Determination by meter method; organic matter content was determined by dilution heat method; humic acid content was determined by the method described in NY / T 1971. Taking the existing soilless cultivation and che...

Embodiment 3

[0053] The high-efficiency humic acid fertilizer used in this example is formed by adding humic acid after the biogas slurry is concentrated 10-20 times. In June 2016, a continuous comparison test was started, and different seasons, different raw material ratios, and different fermentation times were collected in batches. The biogas slurry was tested for its nutritional components and physical and chemical properties. The pH value and EC value of high-efficiency humic acid fertilizer were measured by METTLER TOLEDO SevenEasy acidity meter and DDBJ-350 portable conductivity meter; the contents of available nitrogen, phosphorus and potassium were measured by alkaline solution diffusion method, sodium bicarbonate method, ammonium acetate-flame photometry Determination by meter method; organic matter content was determined by dilution heat method; humic acid content was determined by the method described in NY / T 1971. Taking the existing soilless cultivation and chemical fertilize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com