Marine fuel oil stability additive and preparation method thereof

A fuel oil and stability technology, applied in the field of fuel oil additives, can solve the problems of clogging the filter, high viscosity, and inability to use the blended oil normally, achieving strong adsorption and dispersibility, preventing self-association, and excellent fuel oil stability. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

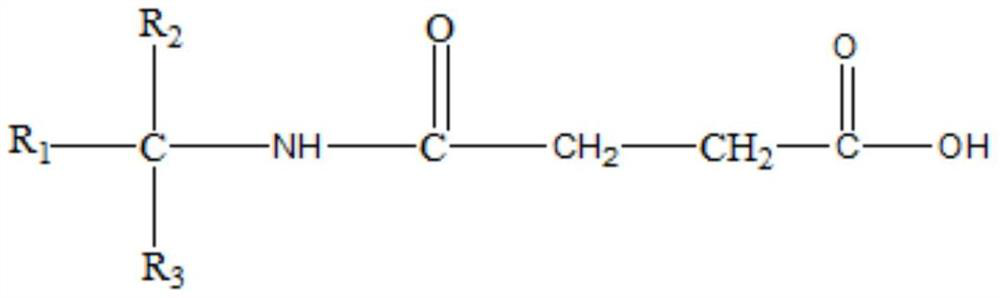

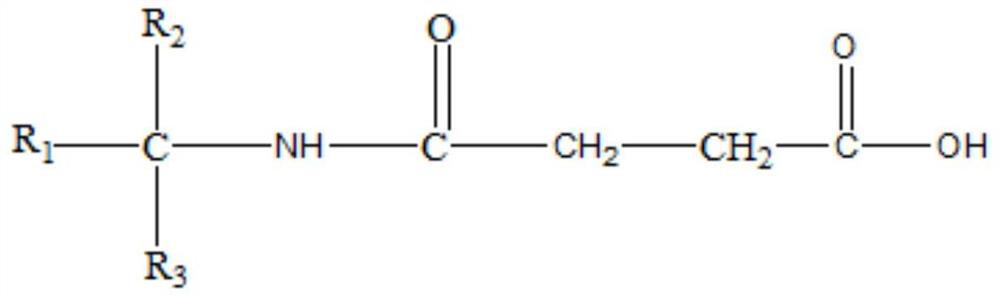

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1: the preparation of marine fuel oil stabilizer A

[0015] Add 100mL of dichloromethane into a 250mL three-necked flask, and slowly add 10.08g of succinic anhydride into the there-necked flask under uniform stirring, and the succinic anhydride will gradually dissolve under stirring conditions. Then weigh 7.36g C8-C10 tertiary alkyl primary amine and dissolve it in dichloromethane, then put it into a constant pressure funnel. At 10°C, the dichloromethane solution of C8-C10 tertiary alkyl primary amines was slowly added dropwise to the three-necked flask, and the reaction was continued for 5.0 h after the dropwise addition was completed. After the reaction, the white precipitate at the bottom of the bottle is the target product of amic acid, and the filtered filter cake is washed three times with dichloromethane, recrystallized with acetone, and vacuum-dried at 85°C for 24 hours to obtain the final amic acid product. Amic acid product 12.71g was weighed, and ...

Embodiment 2

[0016] Embodiment 2: the preparation of marine fuel oil stabilizer B

[0017] Add 100mL of dichloromethane into a 250mL three-necked flask, and slowly add 12.06g of succinic anhydride into the there-necked flask with uniform stirring, and the succinic anhydride will gradually dissolve under stirring conditions. Then weigh 8.75g C12-C14 tertiary alkyl primary amine and dissolve it in dichloromethane, then put it into a constant pressure funnel. At 15°C, the dichloromethane solution of C12-C14 tertiary alkyl primary amines was slowly added dropwise to the three-necked flask, and the reaction was continued for 6.0 h after the dropwise addition was completed. After the reaction, the white precipitate at the bottom of the bottle is the target product of amic acid, and the filtered filter cake is washed three times with dichloromethane, recrystallized with acetone, and vacuum-dried at 85°C for 24 hours to obtain the final amic acid product. 13.80 g of the amic acid product was weig...

Embodiment 3

[0018] Embodiment 3: the preparation of marine fuel oil stabilizer C

[0019] Add 100mL of dichloromethane into a 250mL three-necked flask, and slowly add 13.97g of succinic anhydride into the there-necked flask with uniform stirring, and the succinic anhydride will gradually dissolve under stirring conditions. Then weigh 10.12g C12-C14 tertiary alkyl primary amine and dissolve it in dichloromethane, then put it into a constant pressure funnel. At 30°C, the dichloromethane solution of C12-C14 tertiary alkyl primary amines was slowly added dropwise to the three-necked flask, and the reaction was continued for 7.0 h after the dropwise addition was completed. After the reaction, the white precipitate at the bottom of the bottle is the target product of amic acid. The filtered filter cake was washed three times with dichloromethane, recrystallized with acetone, and dried in vacuum at 85°C for 24 hours to obtain the final amic acid product. Amic acid product 14.42g was weighed, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com