Viscosity reduction type water reducing agent and preparation method thereof

A water-reducing agent and viscosity-reducing technology, which is applied in the field of building materials, can solve the problems of fresh concrete bleeding, prolonging the form removal cycle, and increasing costs, and achieve a significant effect of reducing viscosity, reducing energy consumption, and reducing HLB values. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

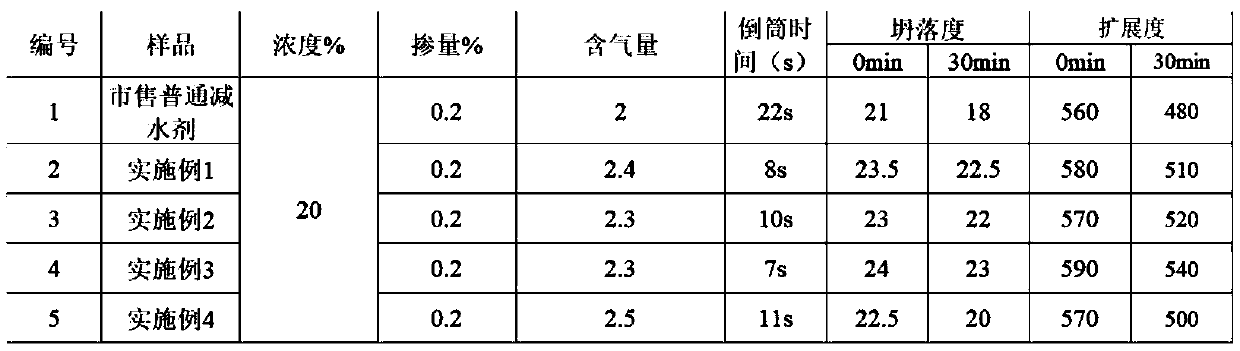

Examples

Embodiment 1

[0040] Dissolve 27g of acrylic acid and 30g of hydrogen phosphate bis(methacryloyloxyethyl) in 40g of deionized water, stir evenly to obtain a monomer solution for use; dissolve 2g of mercaptopropionic acid and 1.06g of sodium formaldehyde sulfoxylate In 59.2 g of deionized water, stir evenly to obtain a chain transfer agent solution for use; 200 g of methyl alkenyl polyoxyethylene ether with a polymerization degree of 54 and a molecular weight of 2400, 150 g of a polyoxyethylene polyoxyethylene ether with a polymerization degree of 56 and a molecular weight of 2400 Put butyl vinyl polyglycol ether and 120g deionized water into the reaction vessel and heat to dissolve. After the complete dissolution and the temperature reaches 20°C, add the mixed solution of 2.67g hydrogen peroxide and 0.27g ferrous sulfate and keep stirring for 5min, then Add 14g of acrylic acid, and after 5 minutes, start to add the monomer solution and chain transfer agent solution dropwise at a constant spe...

Embodiment 2

[0042]Dissolve 35g of acrylic acid and 20g of methacryloyloxyethyl phosphate in 42g of deionized water, stir well to obtain a monomer solution for use; dissolve 1g of mercaptopropionic acid and 2.66g of sodium formaldehyde sulfoxylate in 60g of deionized In water, stir evenly to obtain a chain transfer agent solution for use; 200g of ethoxy vinyl polyglycol ether with a degree of polymerization of 60 and a molecular weight of 3000 and 160g of isobutylene alcohol polyoxyethylene with a degree of polymerization of 60 and a molecular weight of 3000 Add ether and 120g deionized water into the reaction vessel and heat to dissolve. After the solution is completely dissolved and the temperature reaches 25°C, add a mixed solution of 2.66g hydrogen peroxide and 0.26g ferrous sulfate and keep stirring for 3 minutes. Add the monomer solution and the chain transfer agent solution dropwise for 0.45 hours, then continue the heat preservation reaction for 1.5 hours. After the reaction, add aq...

Embodiment 3

[0044] Dissolve 20g of acrylic acid, 12g of hydrogen phosphate bis(methacryloyloxyethyl) phosphate, and 12g of methacryloyloxyethyl phosphate in 350g of deionized water, and stir evenly to obtain a monomer solution for use; Acid and 3.2g sodium formaldehyde sulfoxylate, 0.8g ferrous sulfate are dissolved in 50g deionized water, stir evenly, get the chain transfer agent solution stand-by; 220g polymerization degree is 34, the molecular weight is 2000 hydroxybutyl vinyl Polyethylene glycol ether and 230g of polyglycol ether with a degree of polymerization of 60 and a molecular weight of 3000 and 100g of deionized water were put into a reaction vessel and heated to dissolve. After the solution was completely dissolved and the temperature reached 20°C, 4g of hydrogen peroxide was added. The solution was kept and stirred for 6 minutes, then 12 g of acrylic acid was added, and after 5 minutes, the monomer solution and the chain transfer agent solution were added dropwise at a constan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com