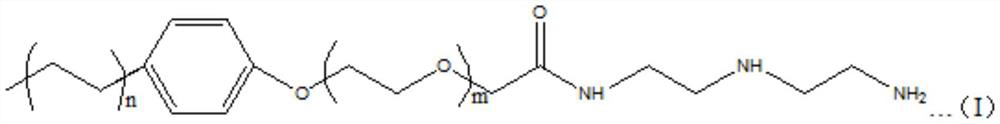

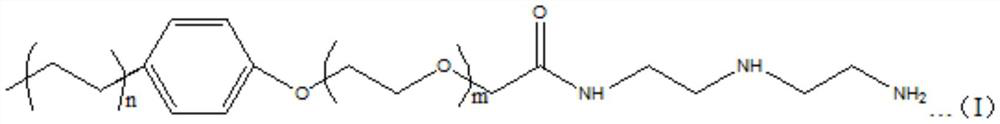

Marine fuel oil stability additive and preparation method thereof

A fuel oil and stability technology, applied in the direction of fuel additives, fuel, carboxylate preparation, etc., can solve the problems of no fluidity, poor combustibility, inefficient use of petroleum resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

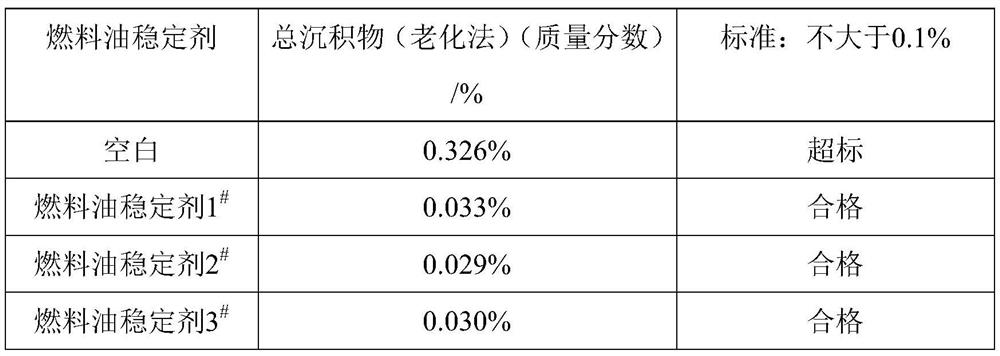

Examples

Embodiment 1

[0014] Embodiment 1: marine fuel oil stabilizer 1 # preparation of

[0015] (1) Heat 40.0g of alkylphenol polyoxyethylene ether with four epoxy groups to 45°C, add 14g of sodium hydroxide to alkalize for 2 hours, add 30g of acetone, and add chlorine at 45°C under uniform stirring. 15.3 g of acetic acid carried out SN2 nucleophilic substitution and addition reaction for 4 hours. After the reaction was completed, adjust the temperature to 58° C. to distill off the acetone to obtain light yellow viscous alkylphenol polyoxyethylene ether carboxylate. Pickle the product with 2000ml of 0.2M dilute hydrochloric acid solution and heat appropriately to promote the separation of the organic phase and the water phase, collect the organic phase containing the alkylphenol polyether carboxylic acid and wash it with distilled water to obtain the alkylphenol polyoxyethylene ether Carboxyl 39.78g, alkylphenol polyoxyethylene ether carboxy yield is 86.47%.

[0016] (2) Blend 39.78g of the al...

Embodiment 2

[0017] Embodiment 2: marine fuel oil stabilizer 2 # preparation of

[0018] (1) Heat 49g of alkylphenol polyoxyethylene ether with six epoxy groups to 47°C, add 14g of sodium hydroxide to alkalize for 2 hours, add 30g of acetone, and add chloroacetic acid at 47°C under uniform stirring conditions 18.8g carried out SN2 nucleophilic substitution addition reaction for 4.5 hours. After the reaction is completed, adjust the temperature to 58° C. to distill off the acetone to obtain light yellow viscous alkylphenol polyether carboxylate. Pickle the product with 2000ml of 0.2M dilute hydrochloric acid solution and heat appropriately to promote the separation of the organic phase and the water phase, collect the organic phase containing the alkylphenol polyether carboxylic acid and wash it again with distilled water to obtain the alkylphenol polyoxyethylene ether Carboxylic acid 48.13g, alkylphenol polyoxyethylene ether carboxylic acid yield is 87.33%.

[0019] (2) Blend 48.13g of ...

Embodiment 3

[0020] Embodiment 3: marine fuel oil stabilizer 3 # preparation of

[0021] (1) Heat 32.0g of alkylphenol polyoxyethylene ether with two epoxy groups to 50°C, add 14g of sodium hydroxide to alkalize for 2 hours, add 30g of acetone, and add chlorine at 50°C under uniform stirring conditions Acetic acid 22g carried out SN2 nucleophilic substitution addition reaction for 5 hours. After the reaction was completed, adjust the temperature to 58° C. to distill off the acetone to obtain light yellow viscous alkylphenol polyoxyethylene ether carboxylate. Pickle the product with 2000ml of 0.2M dilute hydrochloric acid solution and heat appropriately to promote the separation of the organic phase and the water phase, collect the organic phase containing the alkylphenol polyoxyethylene ether carboxylic acid and wash it again with distilled water to obtain the alkylphenol polyoxyethylene Vinyl ether carboxylic acid 33.85g, alkylphenol polyoxyethylene ether carboxylic acid yield was 88.17...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com