High-strength container steel plate and preparation method thereof

A steel plate and container technology, applied in the field of steel plate manufacturing, can solve problems not related to heat treatment performance, achieve excellent plasticity and toughness, thin steel plate, and improve plasticity and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

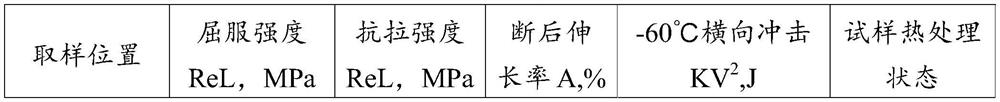

Embodiment 1

[0033] A high-strength container steel plate and preparation method thereof after 10 mm simulated welding heat treatment.

[0034] The chemical composition of the steel sheet is: C 0.12%, Si 0.24%, Mn 1.09%, P0.014%, S 0.002%, Al 0.024, Nb 0.021%, Ti 0.011%, Cr 0.205%, and slang. For Fe and inevitable impurity elements.

[0035] The manufacturing process of the steel sheet is as follows:

[0036] The specific operation of the main process is as follows:

[0037] Kr iron water deulfur: before iron water, the rear slag is clean, the slag layer is 9mm thick, the iron water S: 0.005%;

[0038] Converter control terminal: P: 0.012%, S: 0.005%; C-T coordinate steel, slope thickness 35mm; refining process: LF furnace white slag out steel, feeding calcium lines after processing, Feeding Calculations 2.0m / t; VD vacuum Require 70Pa, hold the time of 18 minutes to ensure the bottom of the bottom of the argon 23min;

[0039] Continuous casting process: overheating (12-18 ° C) and full argon...

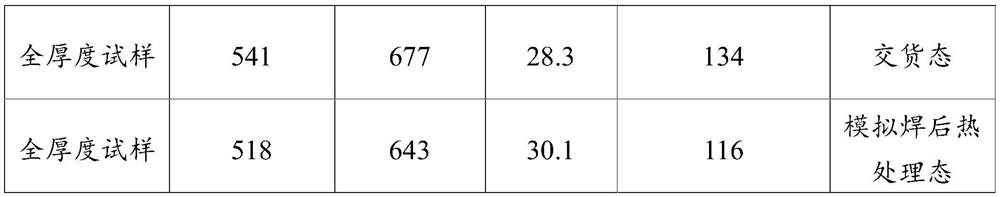

Embodiment 2

[0049] High-strength container steel plate and preparation method thereof after the heat treatment after 50 mm simulated welding.

[0050] The chemical composition of the steel sheet is: C 0.15%, Si 0.28%, Mn 1.33%, P0.011%, S 0.002%, Al 0.033, Nb 0.028%, Ti 0.017%, CR 0.285%, and slang. For Fe and inevitable impurity elements.

[0051] The manufacturing process of the steel sheet is as follows:

[0052] The specific operation of the main process is as follows:

[0053] Kr iron water deulfur: Before the iron water, the rear slag is clean, the slag layer is 10mm thick, the iron water S: 0.005%;

[0054] Converter control terminal: P: 0.010%, S: 0.005%; C-T coordinated steel and slag thickness of 30 mm;

[0055] Refining: LF furnace white slag out steel, feeding calcium lines 2.0m / t after processing; VD vacuum requirements 70 pa, hold time of 25min, to ensure 30 min of argon;

[0056] Continuous casting process: overheating (10-18 ° C) and full argon protection casting, continuous...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com