MEMS gyroscope

A gyroscope and resonant block technology, applied in the field of gyroscopes, can solve problems such as insufficient drive/detection sensitivity, and achieve the effects of reducing MEMs mechanical noise, improving sensitivity, and improving Coriolis gain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

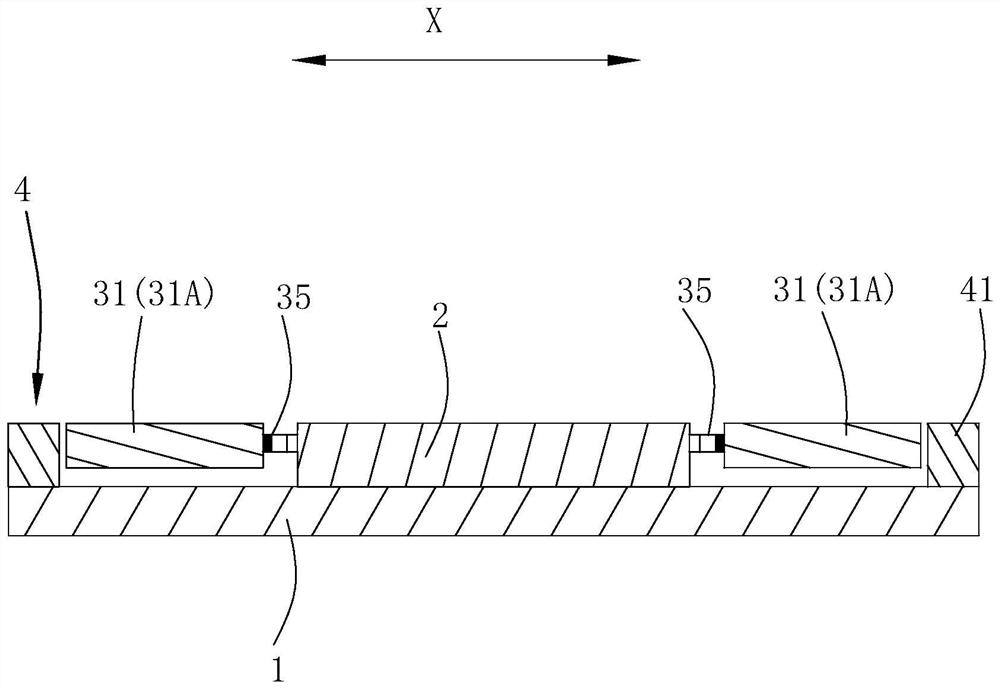

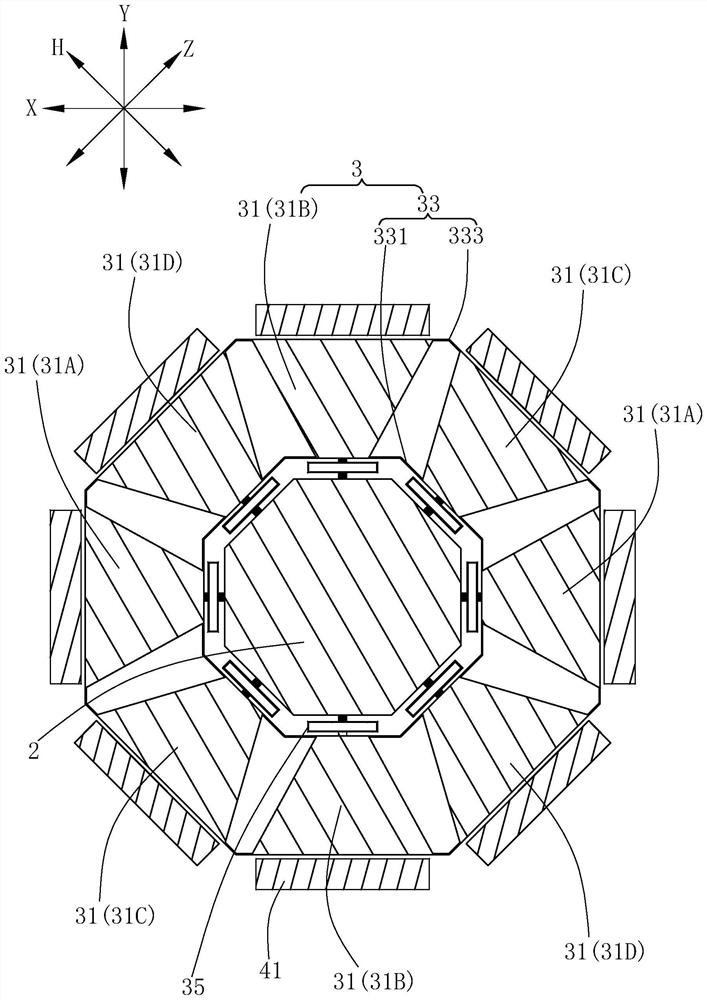

[0034] Please refer to Figure 1 to Figure 3 , the MEMS gyroscope includes a substrate 1 , an anchor point 2 , a resonator 3 and a transducer 4 . The anchor point 2 and the transducer 4 are fixed on the base 1 , and the resonator 3 is suspended on the base 1 .

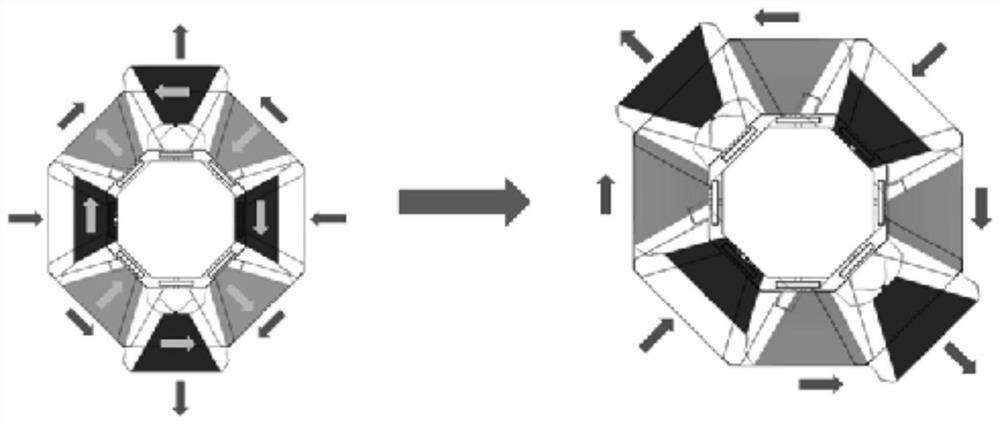

[0035] Resonator 3 adopts a fully symmetrical design. Specifically, the resonator 3 includes eight resonant blocks 31 distributed in a ring and equally spaced along the circumferential direction of the anchor point 2 , and a coupling beam 33 connecting two adjacent resonant blocks 31 . Among them, the eight resonant blocks 31 are divided into a pair of first resonant blocks 31A arranged at intervals along the first axis X, a pair of second resonant blocks 31B arranged at intervals along the second axis Y, and a pair of second resonant blocks 31B arranged at intervals along the third axis Z. A pair of third resonant blocks 31C and a pair of fourth resonant blocks 31D arranged at intervals along the fourth axis H. Whe...

Embodiment 2

[0049] Please refer to Figure 4 to Figure 5 The difference between the second embodiment and the first embodiment is that the transducer 4 includes 8N internal electrodes 43, and the resonant block 31 is provided with N jacks 311 along the axial direction of the anchor point 2, and the internal electrodes 43 correspond to each other. The internal electrode 43 corresponding to the first resonant block 31A and the internal electrode 43 provided corresponding to the second resonant block 31B have opposite potentials; the internal electrode 43 corresponding to the third resonant block 31C and the corresponding The internal electrodes 43 of the fourth resonant block 31D have opposite potentials; N is a positive integer, and when N is greater than 1, the N sockets 311 on each resonant block 31 are arranged at intervals along the radial direction of the anchor point 2 .

[0050] In this embodiment, the internal electrode 43 includes a first electrode 431 and a second electrode 433 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com