Method and system for optimizing feed gas supply scheme of multiple hydrogen production devices in refinery plant

A technology of hydrogen production device and optimization method, which is applied in chemical instruments and methods, design optimization/simulation, hydrogen and other directions, can solve the problems of increasing the cost of retrofitting and the loss of shutdown of the device, so as to improve the efficiency of hydrogen production, reduce the cost of hydrogen production, The effect of increased installation and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

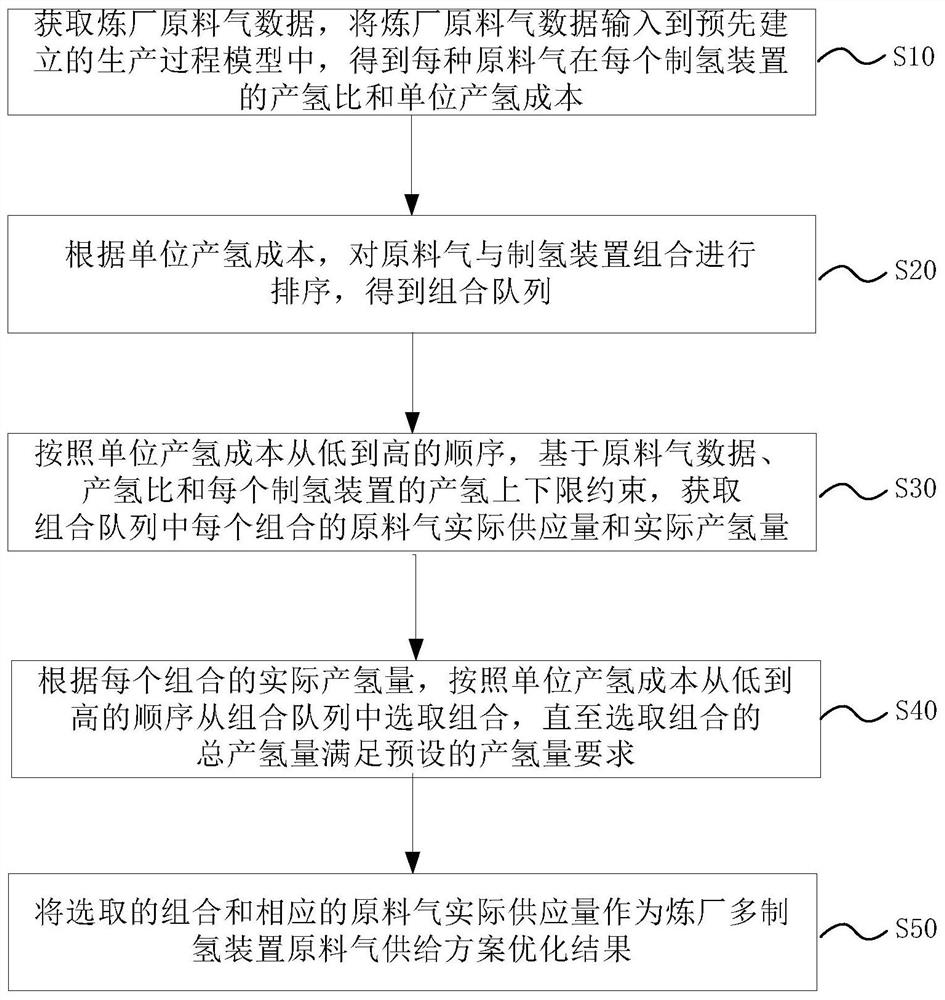

[0077] figure 1 A schematic flow chart of a method for optimizing the raw material gas supply scheme of multiple hydrogen production units in a refinery in one embodiment of the present application is shown. Such as figure 1 As shown, the method for optimizing the raw material gas supply scheme of multiple hydrogen production units in the refinery in this embodiment includes:

[0078] S10. Obtain refinery feed gas data, input the refinery feed gas data into a pre-established production process model, and obtain the hydrogen production ratio and unit hydrogen production cost of each feed gas in each hydrogen production device;

[0079] S20. According to the size of the unit hydrogen production cost, sort the combination of raw material gas and hydrogen production device to obtain a combination queue;

[0080] S30. According to the order of unit hydrogen production cost from low to high, based on the raw material gas data, hydrogen production ratio and hydrogen production uppe...

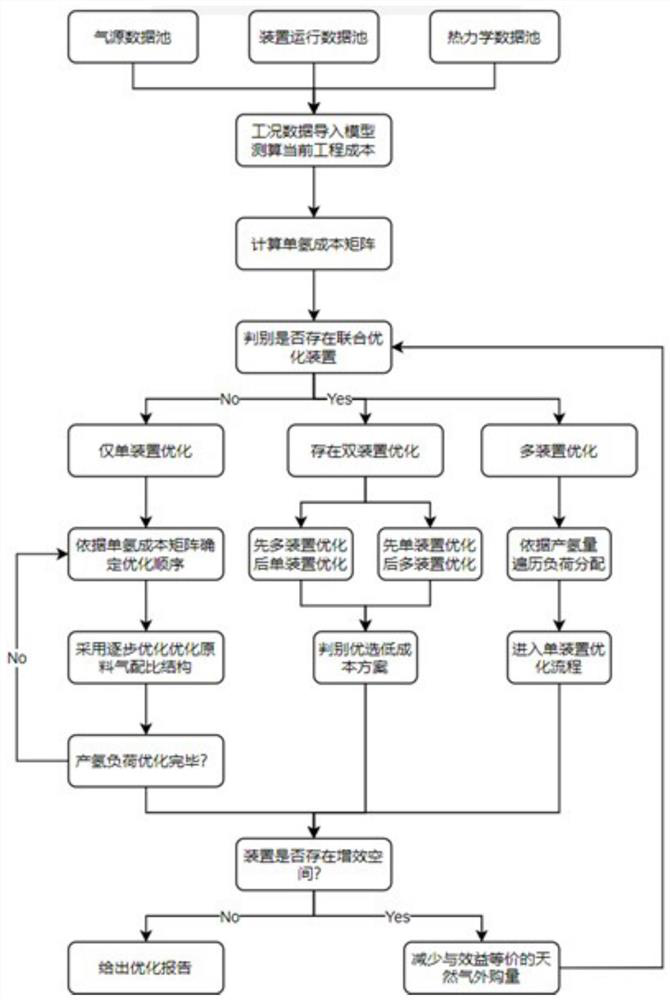

Embodiment 2

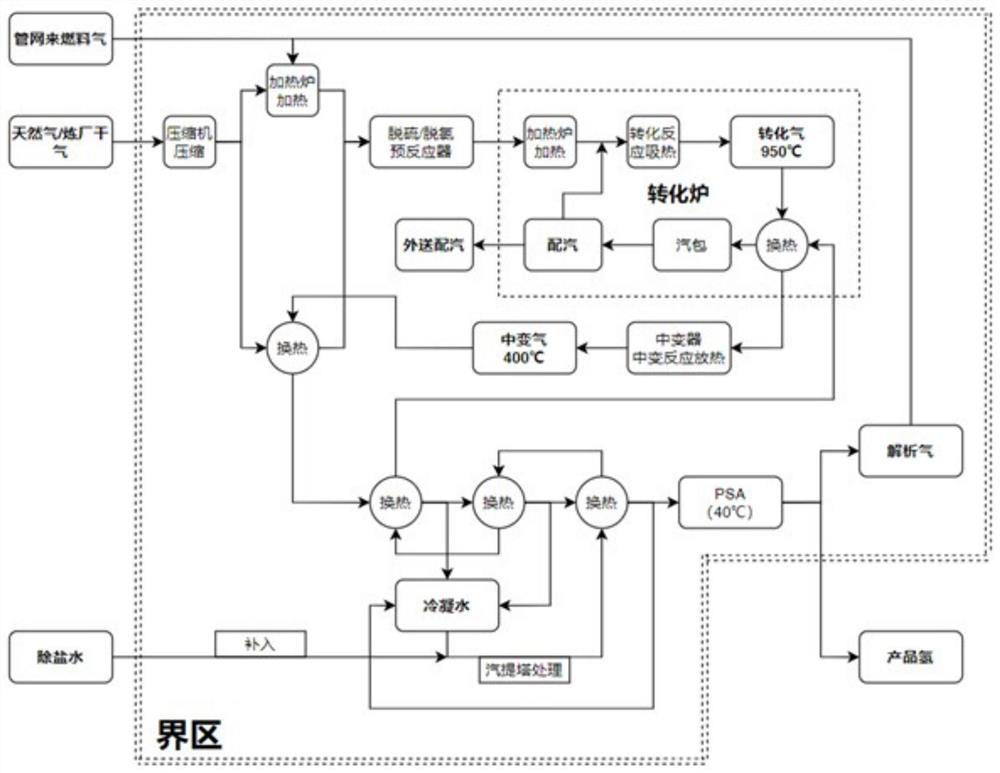

[0160] First, based on the refinery DCS and real-time database, the LIMS analysis data, raw material composition thermodynamic data, and operation data of each hydrogen production unit within 3 months were obtained, and used to establish the production process model of the hydrogen production unit. The main steps are as follows:

[0161] Calculate the equilibrium constant of the reaction process of reformer and intermediate transformer;

[0162] Calculate the composition of medium-change gas based on the flow rate, composition, steam distribution and reaction equilibrium constant of raw gas;

[0163] Repeat steps A and B for each set of data to obtain the calculation results of the medium-change gas composition within 3 months;

[0164] Using the partial least squares regression method, the calculation results of the medium-change gas composition within 3 months are compared and regressed with the actual analysis results of the medium-change gas composition, and the catalyst p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap