TEM (Transmission Electron Microscope) three-dimensional reconstruction sample rod capable of carrying nanometer needle tip sample and automatically rotating 360 degrees

A three-dimensional reconstruction and sample rod technology, which is applied to circuits, discharge tubes, electrical components, etc., can solve the problems that the TEM three-dimensional reconstruction sample rod cannot solve, the loss of structural information in the observation area, and the loss of micro-structural information, so as to improve success. rate and resolution limits, elimination of missing wedges, easy sampling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

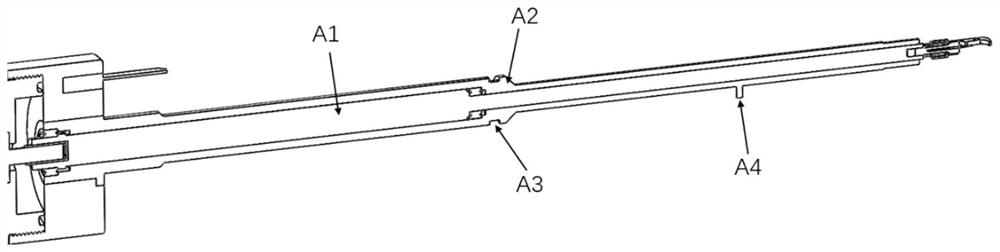

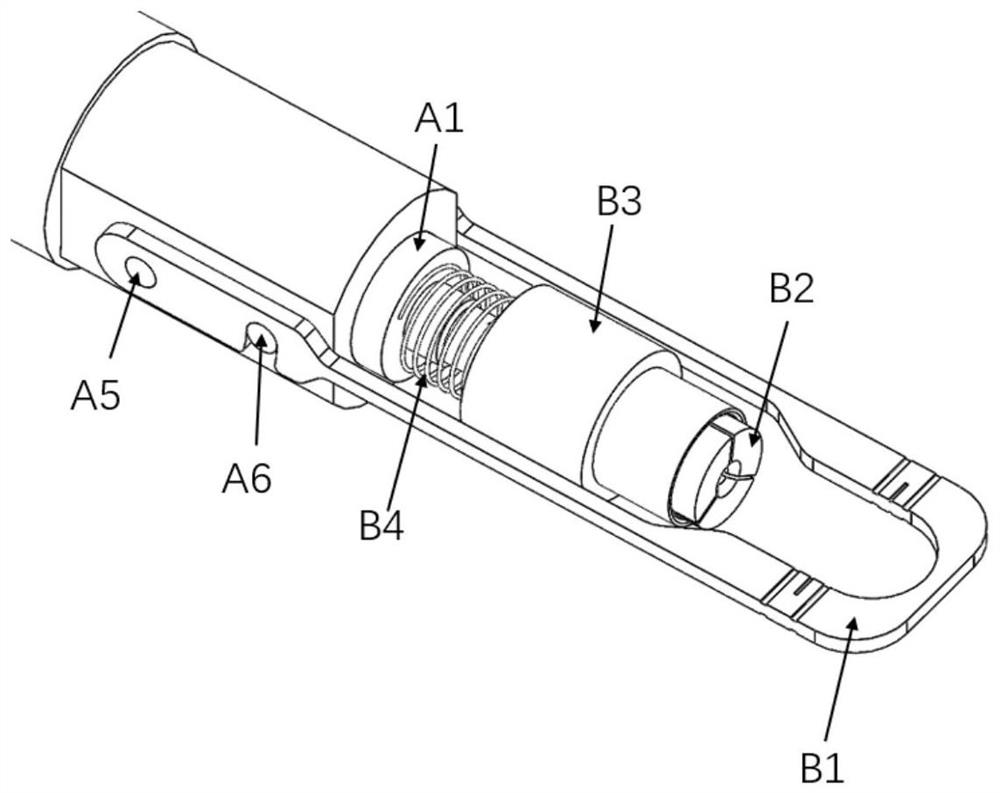

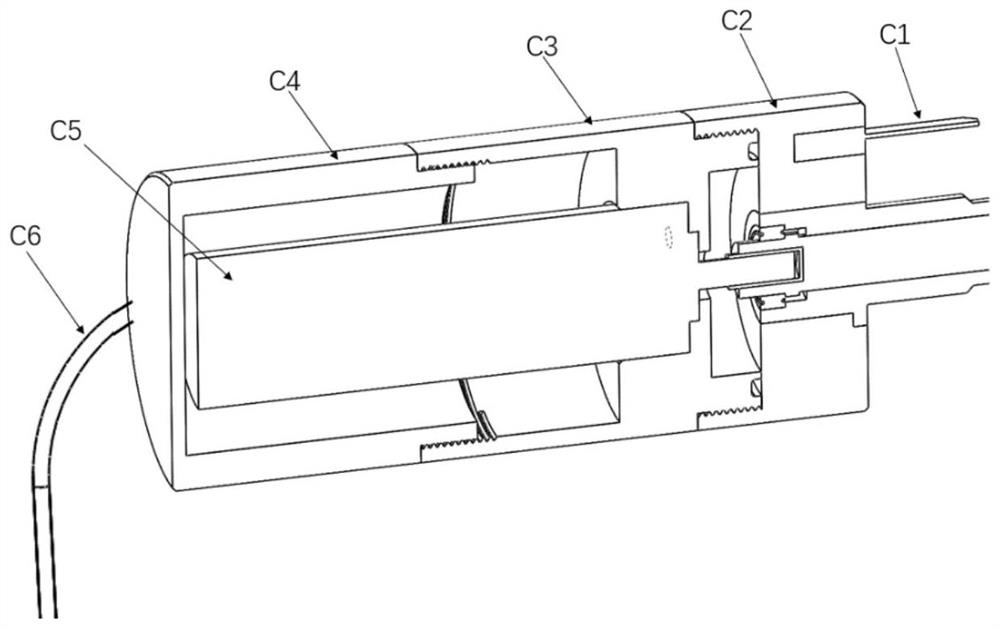

[0038] The invention is a TEM three-dimensional reconstructed sample rod capable of carrying a nano-tip sample and autonomously rotating 360°. The nano-tip sample clamping device is located at the front end of the main body of the sample rod. Composed of buckle and spring return device. The nano-tip protective cover is connected to the main body of the sample rod through a fixed pin and a buckle. For convenience during sample loading, the protective cover can be pulled up to avoid interfering with the sample loading process. After the sample is installed, reset the protective cover and fix it with the buckle , it can protect the nano-needle tip from being damaged when the sample rod is pulled out. The nano needle tip is fixed with a special copper tube. When loading the sample, use a special tool to push the locking buckle to the end of the rod, the jaw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com