Natto with weight-losing, lipid-lowering and anti-inflammatory effects as well as preparation method and application of natto

A natto and lipid-lowering technology, applied in the field of natto and its preparation, can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

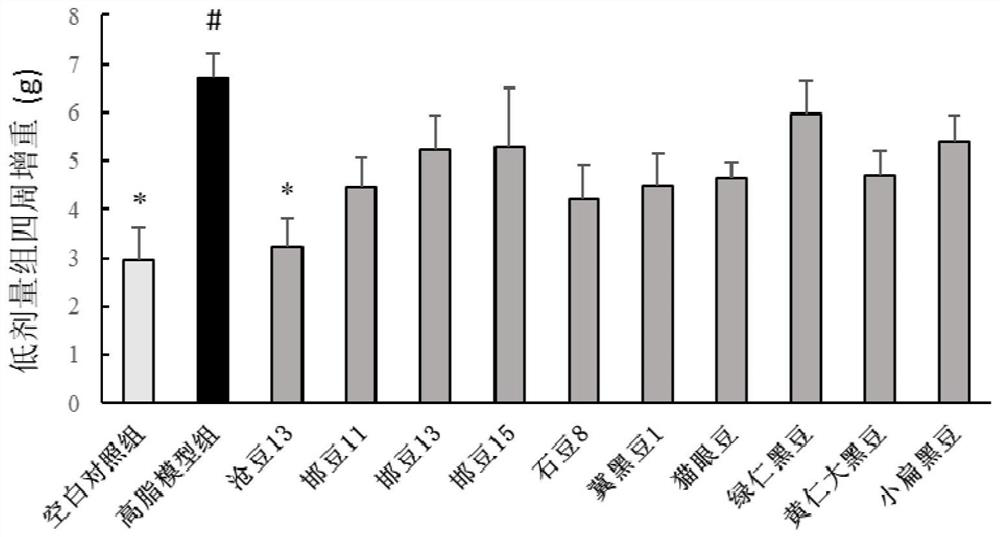

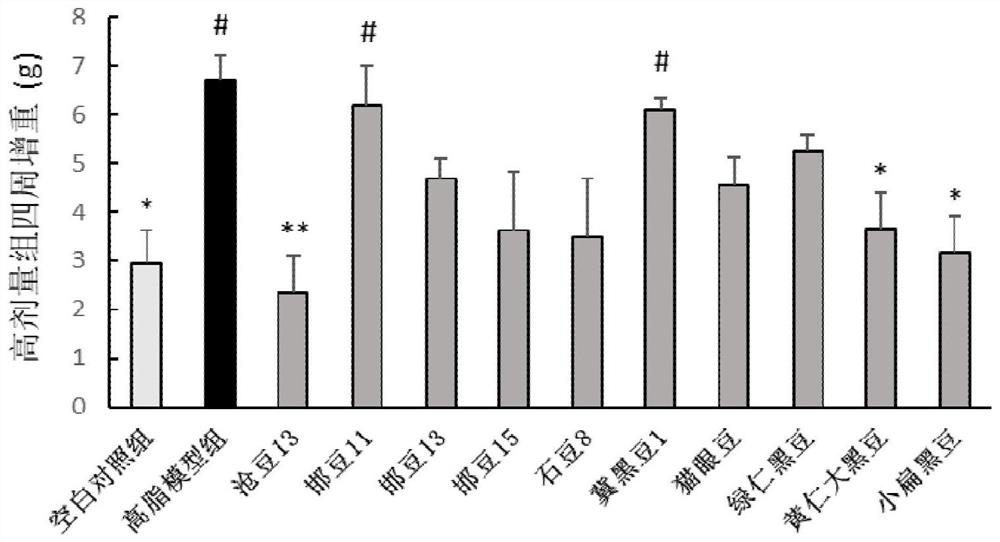

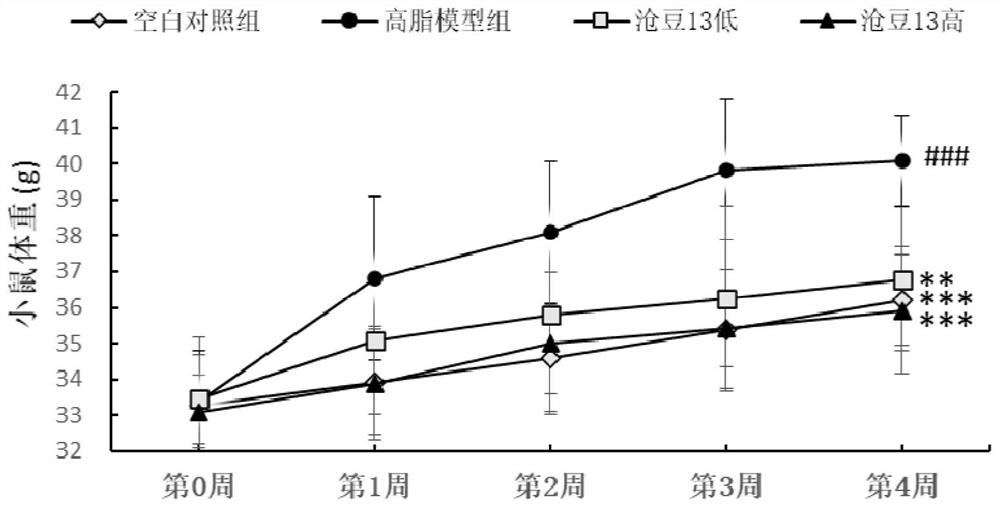

Image

Examples

Embodiment 1

[0040] The method for preparing natto by Bacillus subtilis HAU-SDZ6 fermentation soybean:

[0041] Melt the glycerol tube frozen preservation strain of Bacillus subtilis HAU-SDZ6, inoculate it into LB liquid medium according to the inoculum amount of 1% (v / v), cultivate it at 37°C for 48 hours, and obtain the activated bacterial liquid; solution was inoculated into LB liquid culture medium according to the inoculum amount of 1% (v / v), put into a shaking table 180r / min, and cultivate at 37°C for 12h to obtain the culture solution of the Bacillus subtilis HAU-SDZ6; The solution was centrifuged at 8000r / min, the supernatant was removed, and the obtained bacterium sludge was resuspended in sterilized distilled water to obtain the bacterium solution of the Bacillus subtilis HAU-SDZ6 (OD value above 4.0).

[0042] Select Cang Dou 13 with full granules and no obvious moth-eaten damage, clean it, put Cang Dou 13 in a natto machine, add water three times the volume of Cang Dou 13, soak...

Embodiment 2

[0044] Preparation of freeze-dried bacterial powder:

[0045] Preparation of protective agent solution: 7.5% sucrose, 10% skimmed milk powder, the rest of deionized water, sterilized in a high-pressure steam sterilizer at 115°C for 15 minutes; 12.5% of maltodextrin, the rest of deionized water, and sterilized by high-pressure steam at 121°C Sterilize in the bacteria pot for 15 minutes, mix well and use.

[0046] Take the Bacillus subtilis HAU-SDZ6 culture solution (OD value above 7.0) in the stable phase and place it in a low-temperature centrifuge at 4°C, centrifuge at 8000r / min for 10min, discard the supernatant, collect the sludge, and add 1mL to the sludge Protective agent solution, mixed evenly, put into -80 ℃ refrigerator to pre-freeze for 2 hours, turn on the vacuum freeze dryer to pre-cool for 30 minutes in advance, put the mixed solution of pre-frozen bacteria slime and protective agent solution into the freeze dryer for 24 hours to freeze-dry , to obtain freeze-dr...

Embodiment 3

[0051] Production of natto freeze-dried powder:

[0052] After cooling the fermented natto at room temperature, put it in a -80°C refrigerator to pre-freeze for 2 hours, turn on the vacuum freeze dryer for pre-cooling for 30 minutes in advance, put the pre-frozen natto in the vacuum freeze dryer for 24 hours, and take it out for use After being pulverized by a grinder, it is transferred to a vacuum bag for vacuuming to obtain natto freeze-dried powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com