Flue gas treatment intelligent operation optimization control system and method

A technology for operation optimization and control system, applied in chemical instruments and methods, separation methods, program control devices, etc. Good real-time response capability, improved fault tolerance, and the effect of flue gas safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

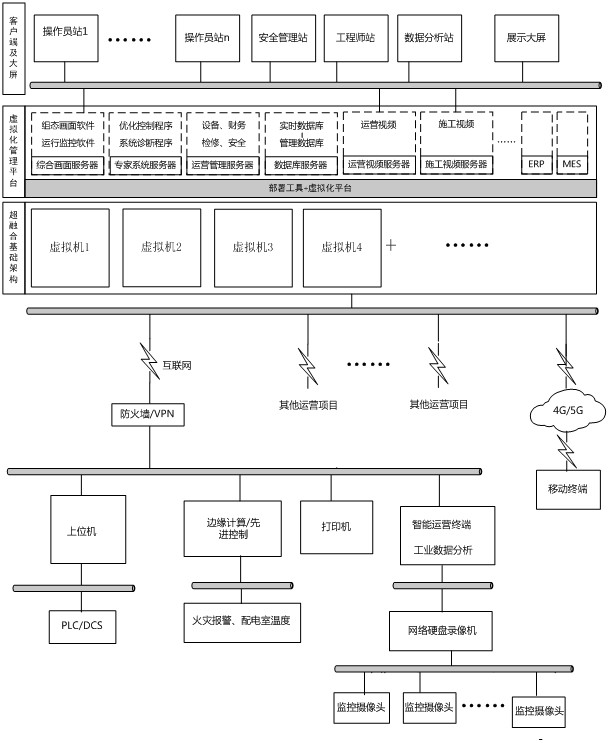

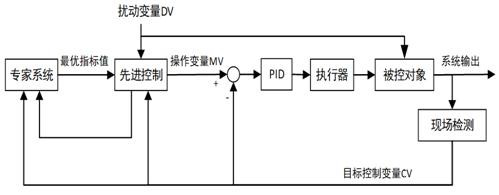

[0053] In one or more embodiments, a flue gas treatment intelligent operation optimization control system is disclosed, referring to figure 1 , the whole system is divided into three-layer architecture, the upper-layer architecture is arranged in the operation management and control center, with the hyper-converged infrastructure as the core, and virtual machines are built according to different business functions, and different business function software runs in the corresponding virtual machines; the middle architecture and The low-level architecture is arranged on site. The low-level architecture includes on-site PLC / DCS, field instruments, and actuators. The intermediate architecture mainly includes edge controllers, IoT acquisition gateways, and industrial firewalls. Level of control, level of security.

[0054] In this embodiment, the flue gas treatment intelligent operation optimization control system includes a flue gas treatment device, a system control unit, an edge ...

Embodiment 2

[0084] In one or more embodiments, a smart operation optimization control method for flue gas treatment is disclosed, which specifically includes the following process:

[0085] (1) Detect the operation data of each flue gas treatment device in real time and send it to the edge controller;

[0086] (2) When a certain operating data exceeds the set safety threshold range, the edge controller sends an instruction to control the corresponding flue gas treatment device to adjust the operating data;

[0087] (3) The edge controller sends the received operating data to the hyper-converged server through the network, so that the hyper-converged server can realize comprehensive picture service, expert system service, operation management service and database service.

[0088] Specifically, the safety threshold ranges are respectively preset for various operating data in the flue gas treatment device;

[0089] After the system is powered on, each unit starts to run, each equipment in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com