Magnetic MgO adsorbent as well as preparation method and application thereof

An adsorbent and magnetic technology, which is applied in the field of magnetic MgO adsorbent and its preparation, can solve the problems of poor adsorption effect of the adsorbent, and achieve the effect of fast adsorption speed and strong pH value adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

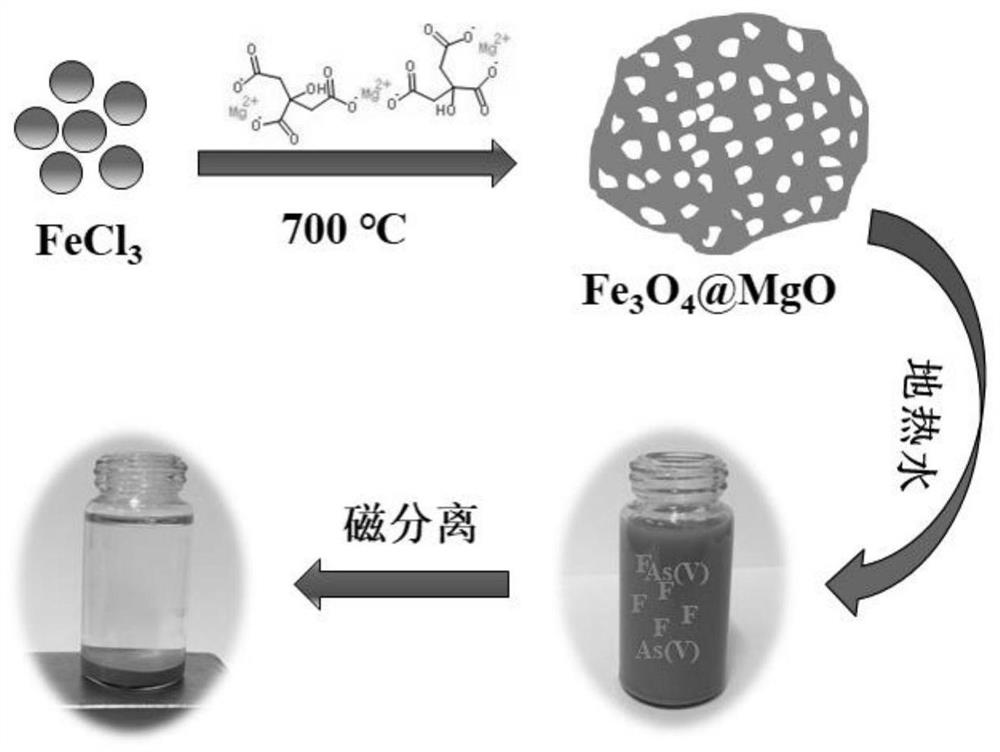

[0036] The invention provides a kind of preparation method of magnetic MgO adsorbent, comprises the following steps:

[0037] Mix the soluble ferric source, magnesium citrate and water, heat and evaporate to obtain the precursor mixture;

[0038] The precursor mixture is calcined to obtain a magnetic MgO adsorbent.

[0039] The invention mixes the soluble ferric iron source, magnesium citrate and water, heats and evaporates to obtain the precursor mixture. In the present invention, the soluble ferric iron source is preferably FeCl 3 , Fe(NO 3 ) 3 and Fe 2 (SO 4 ) 3 one or more of them.

[0040] In the present invention, the magnesium citrate is preferably magnesium citrate nonahydrate.

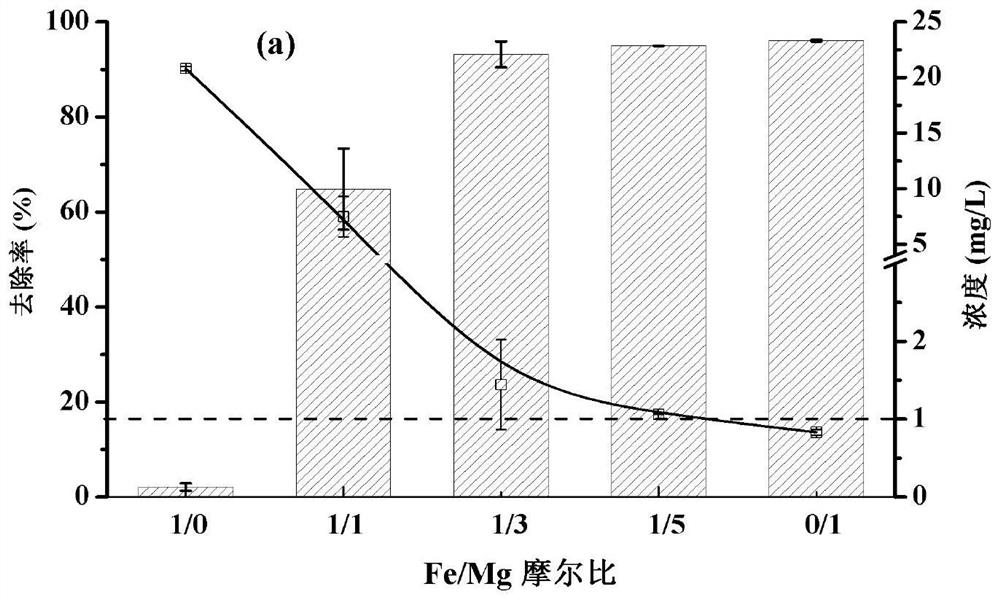

[0041] In the present invention, in the soluble ferric iron source and magnesium citrate, the molar ratio of Fe and Mg is preferably 1:1-5, preferably 1:3.

[0042] In the present invention, the mass ratio of the magnesium citrate to water is preferably 1:20.

[0043] In the present ...

Embodiment 1

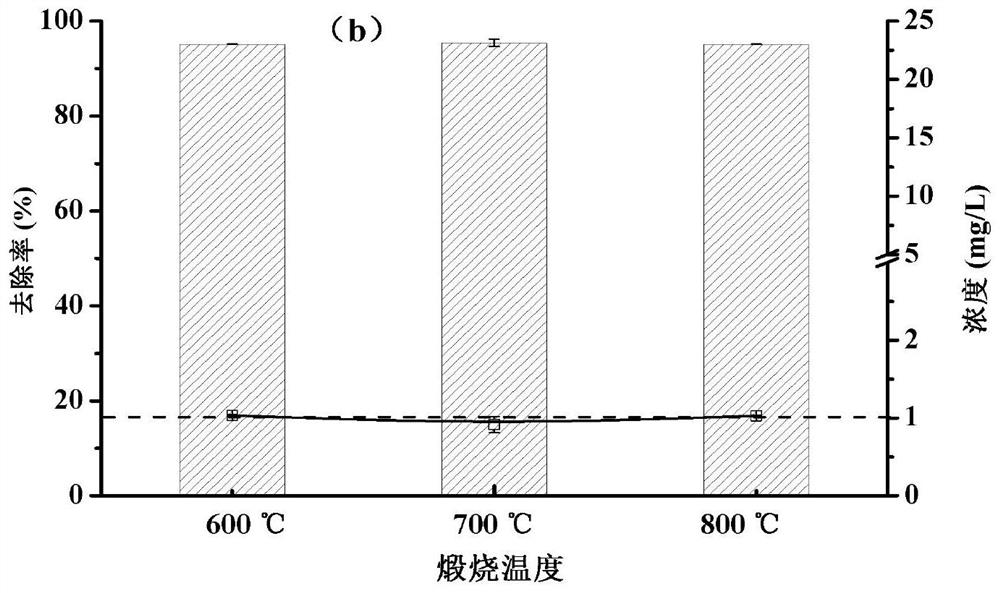

[0057] FeCl 3 Add magnesium citrate to 10mL water, keep the molar ratio of Fe / Mg at 1 / 1, 1 / 3 and 1 / 5 respectively, stir and volatilize in a water bath at 60-90°C, transfer to a muffle furnace for calcination for 1- 5h, the calcination temperatures were 600, 700 and 800°C, and the heating rate was 5°C / min, and the magnetic MgO adsorbent Fe 3 o 4 @MgO.

[0058] For performance comparison, FeCl is omitted 3 The addition of MgO material derived from single magnesium citrate was prepared.

[0059] figure 1 is the adsorbent Fe of the present invention 3 o 4 Schematic diagram of the preparation of @MgO and its removal of fluorine and arsenic from geothermal water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com