Metallized film manufacturing method

A technology of metallized film and production method, which is applied in the direction of chemical instruments and methods, cleaning methods and utensils, metal material coating technology, etc., can solve the problems of difficult control of coating thickness, inclusion of impurities, and easy adhesion of dust, etc. Achieve the effect of increasing the range of blowing, avoiding offset, and good impurity removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

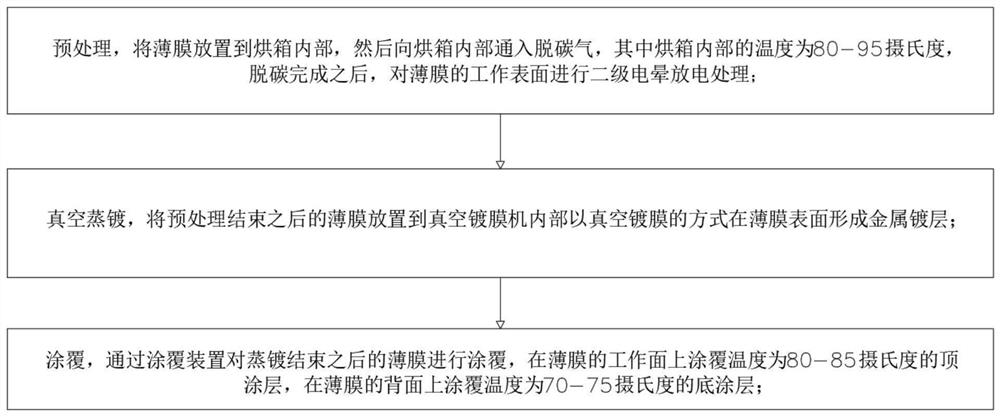

[0038] see figure 1 , the present invention provides a technical solution: a method for making a metallized film, comprising the following steps:

[0039] For pretreatment, the film is placed inside the oven, and then decarburization gas is introduced into the oven, wherein the temperature inside the oven is 80-95 degrees Celsius. After the decarburization is completed, the working surface of the film is subjected to secondary corona discharge treatment;

[0040] Vacuum evaporation, placing the film after pretreatment into the vacuum coating machine to form a metal coating on the surface of the film by vacuum coating;

[0041] Coating, coating the film after evaporation by a coating device, coating a top coating with a temperature of 80-85 degrees Celsius on the working surface of the film, and coating the backside of the film with a temperature of 70-75 degrees Celsius the base coat.

Embodiment 2

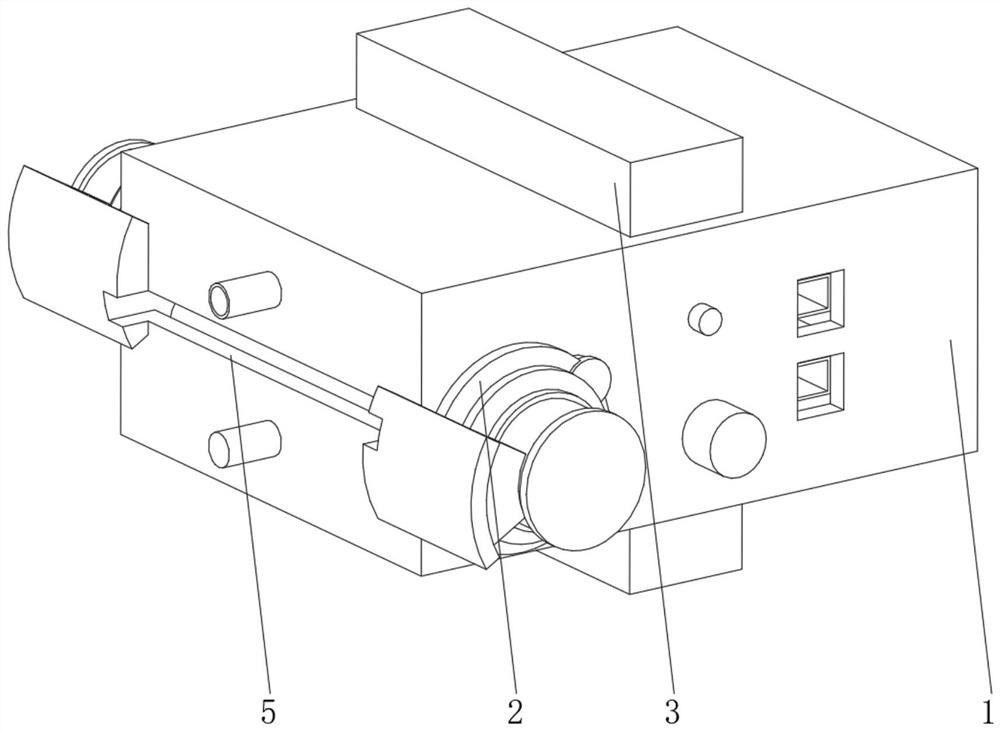

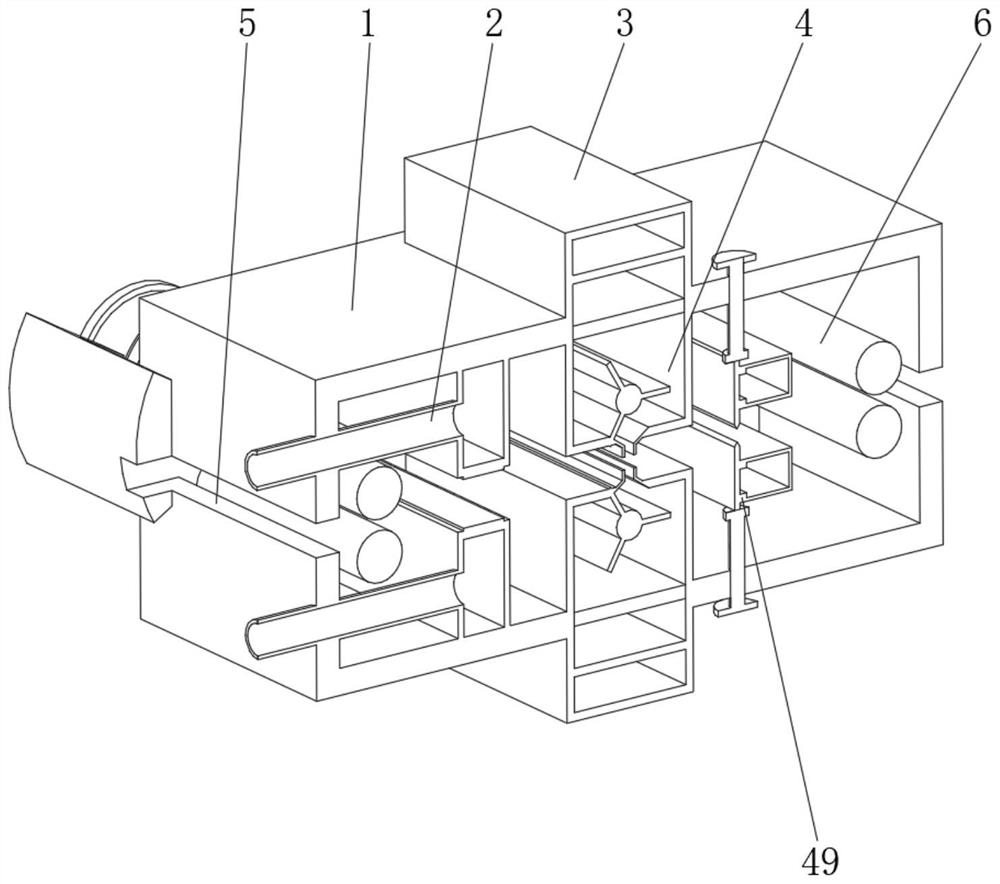

[0043] see Figure 1-4 , on the basis of Embodiment 1, the present invention provides a technical solution: a method for making a metallized film, the coating device includes a coating box 1, and the top and bottom ends of the coating box 1 are fixedly connected with a cleaning device 2. The top and bottom of the coating box 1 are fixedly connected with a heating box 3. The side of the heating box 3 close to the coating box 1 is provided with a coating device 4. The coating device 4 runs through the coating box 1 and extends to the coating box 1 on the side away from the heating box 3. Inside the coating box 1, both sides of the coating box 1 are provided with material openings 5, and the part of the inner wall of the coating box 1 close to the material opening 5 is rotatably connected with a guide roller 6;

[0044] The cleaning device 2 includes an air plate 21. A sliding air port 22 is provided at the bottom of the air plate 21. A dividing air plate 23 is slidably connected...

Embodiment 3

[0049] see Figure 1-5 , on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the coating device 4 includes a coating box 41, the bottom of the coating box 41 is connected with a coating port 42, and the part of the inner wall of the coating box 41 located above the coating port 42 rotates A stirring roller 43 is connected, one end of the stirring roller 43 penetrates the paint box 41 and is fixedly connected with a rotating gear 44, the top of the inner wall of the paint box 41 is fixedly connected with a heat conducting strip 45, the top of the inner wall of the paint box 41 is slidably connected with a pressure plug 46, and the top of the pressure plug 46 is slidably connected. A compression spring 47 is provided, the part of the paint box 41 located below the pressure plug 46 is connected with a feeding pipe 48, one side of the paint box 41 is fixedly connected with a scraping device 49, and the top of the paint box 41 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com