Powder cleaning method for additive manufacturing complex titanium alloy wing rudder part

A technology of additive manufacturing and cleaning method, which is applied in the field of additive manufacturing, can solve the problems such as the difficulty of powder cleaning of wing and rudder parts, and achieve the effects of solving the difficulty of powder cleaning, facilitating mass production, and removing residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

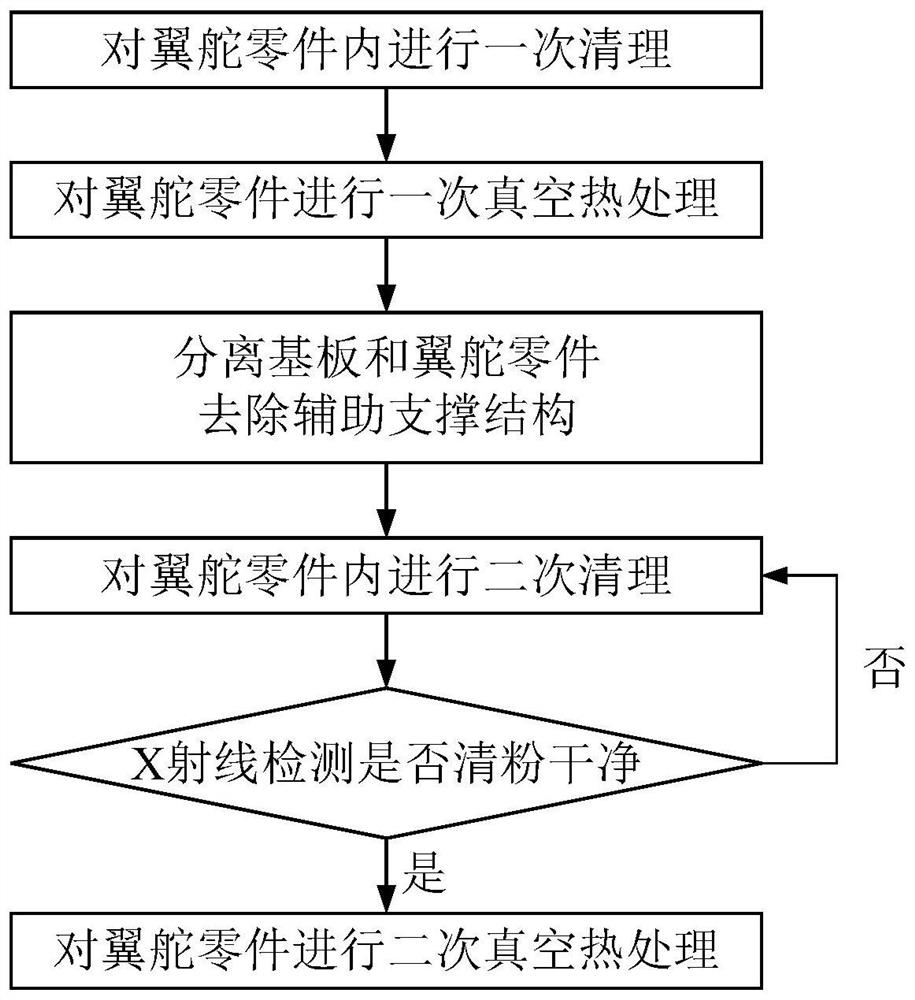

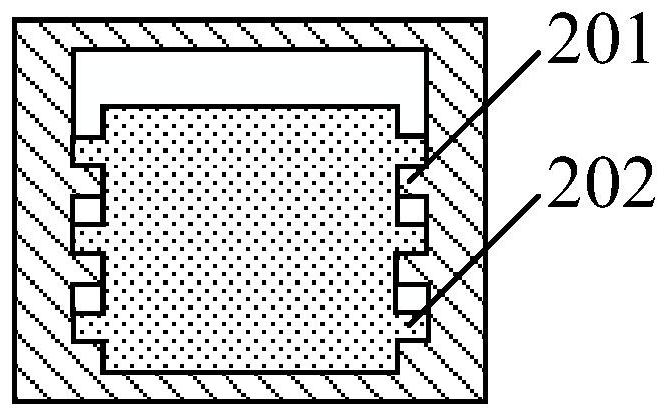

[0077] The powder cleaning method for additively manufacturing complex titanium alloy wing rudder parts provided in this embodiment includes the following steps:

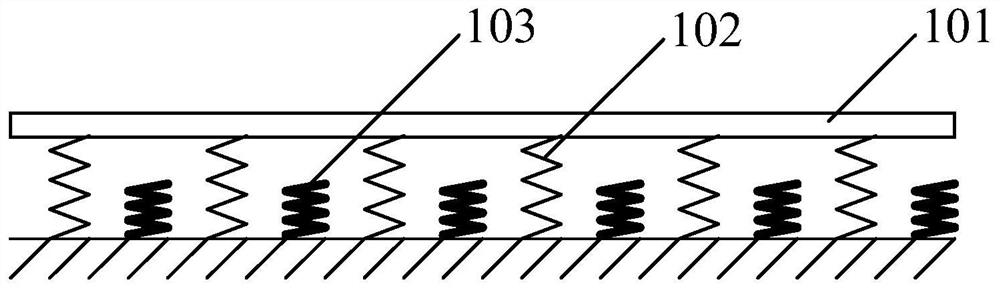

[0078] Step 1: Take the wing rudder parts and the base plate out of the forming cylinder and place them on a mechanical vibration table. While the workpiece is vibrating, use 0.8MPa compressed air to purge the surface and internal cavity of the wing rudder parts until no powder is visible to the naked eye. Most of the powder in the cavity is cleaned up;

[0079] Step 2: Carry out low-temperature vacuum heat treatment on the preliminarily cleaned workpieces including wing rudder parts and substrates. -2 Pa;

[0080] Among them, the cooling process during the low-temperature vacuum heat treatment process is as follows: drop from the holding temperature to 300°C at a cooling rate of 8-12°C / min, keep the temperature for 30 minutes during the cooling stage, and then drop to room temperature at a cooling rate of 4-6°C / mi...

Embodiment 2

[0087] The powder cleaning method for additively manufacturing complex titanium alloy wing rudder parts provided in this embodiment includes the following steps:

[0088] Step 1: Take the wing rudder parts and the substrate out of the forming cylinder and place them on a mechanical vibration table. While the workpiece is vibrating, use 1MPa compressed air to purge the surface of the wing rudder parts and the internal cavity until no powder is visible to the naked eye. Most of the powder in the cavity is cleaned up;

[0089] Step 2: Carry out low-temperature vacuum heat treatment on the preliminarily cleaned workpieces including wing rudder parts and substrates. -3 Pa;

[0090] Among them, the cooling process during the low-temperature vacuum heat treatment process is as follows: drop from the holding temperature to 300°C at a cooling rate of 8-12°C / min, keep the temperature for 45 minutes during the cooling stage, and then drop to room temperature at a cooling rate of 4-6°C / min...

Embodiment 3

[0096] The powder cleaning method for additively manufacturing complex titanium alloy wing rudder parts provided in this embodiment includes the following steps:

[0097] Step 1: Take the wing rudder parts and the substrate out of the forming cylinder and place them on a mechanical vibration table. While the workpiece is vibrating, use 1MPa compressed air to purge the surface of the wing rudder parts and the internal cavity until no powder is visible to the naked eye. Most of the powder in the cavity is cleaned up;

[0098] Step 2: Carry out low-temperature vacuum heat treatment on the preliminarily cleaned workpieces including wing rudder parts and substrates. -2 Pa;

[0099] Among them, the cooling process during the low-temperature vacuum heat treatment process is as follows: drop from the holding temperature to 300°C at a cooling rate of 8-12°C / min, keep the temperature for 45 minutes during the cooling stage, and then drop to room temperature at a cooling rate of 4-6°C / m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com