Polarizer protective film or release film edging separation method

A separation method and polarizer technology, which are applied in the direction of machine tools, grinders, and grinding drive devices suitable for grinding the edge of workpieces, can solve problems such as failure to meet customer needs and different bonding forces, and achieve suitable processing temperatures and increased Friction, effect of improving chip removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

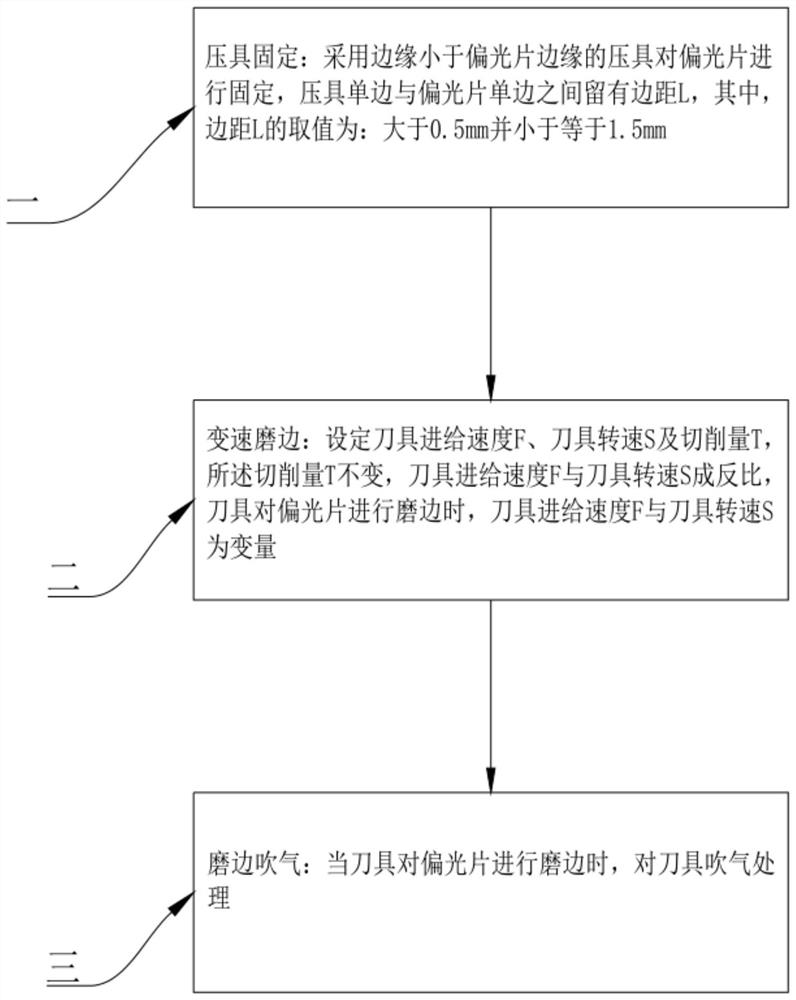

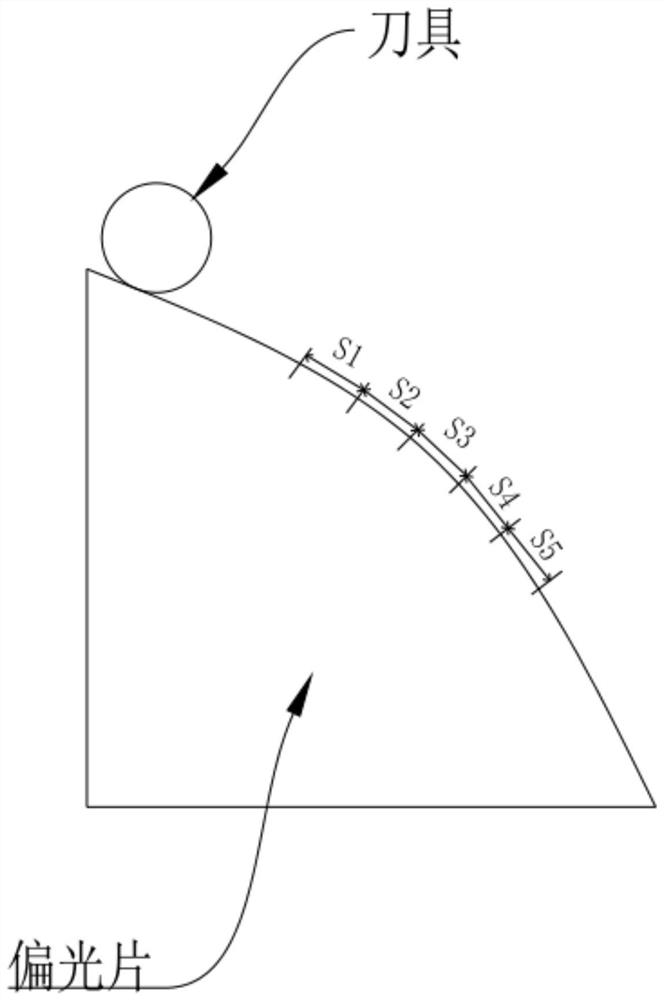

[0023] Such as Figure 1-Figure 3 as shown, figure 1 A flow chart of the method for edging and separating polarizer protective film or release film;

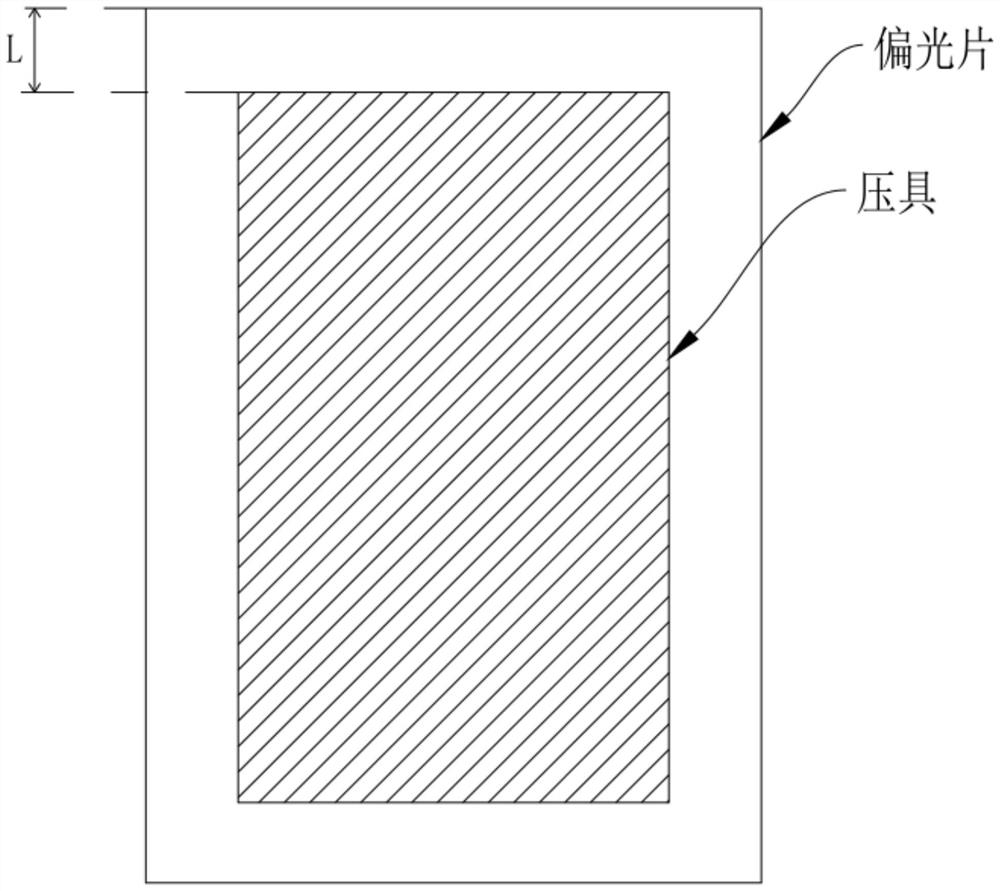

[0024] figure 2 It is a schematic diagram of the position of the presser and the polarizer; image 3 It is a schematic diagram of the edging process of the cutter and the polarizer. The method for edging and separating polarizer protective film or release film of the present application includes:

[0025] (1): Fixing of the press tool: Use the press tool to fix the polarizer to be processed. At the same time, the surface area of the side of the press tool in contact with the polarizer is smaller than the surface area of the polarizer. In other words, after the press tool contacts the polarizer, the pressure There is a margin L between the single side of the tool and the single side of the polarizer, and the value of the margin L is between 0.5 mm and 1.5 mm. In a specific application, the value of the edge distance L i...

Embodiment 2

[0029] Such as Figure 1-Figure 3 as shown, figure 1 A flow chart of the method for edging and separating the polarizer protective film or the release film;

[0030] figure 2 It is a schematic diagram of the position of the presser and the polarizer; image 3 It is a schematic diagram of the edging process of the cutter and the polarizer. The method for edging and separating polarizer protective film or release film of the present application includes:

[0031] (1): Fixing of the press tool: Use the press tool to fix the polarizer to be processed. At the same time, the surface area of the side of the press tool in contact with the polarizer is smaller than the surface area of the polarizer. In other words, after the press tool contacts the polarizer, the pressure There is a margin L between the single side of the tool and the single side of the polarizer, and the value of the margin L is between 0.5mm and 1.5mm. In a specific application, the value of the margin L is...

Embodiment 3

[0035] Such as Figure 1-Figure 3 as shown, figure 1 A flow chart of the method for edging and separating polarizer protective film or release film;

[0036] figure 2 It is a schematic diagram of the position of the presser and the polarizer; image 3 It is a schematic diagram of the edging process of the cutter and the polarizer. The method for edging and separating polarizer protective film or release film of the present application includes:

[0037] (1): Fixing of the press tool: Use the press tool to fix the polarizer to be processed. At the same time, the surface area of the side of the press tool in contact with the polarizer is smaller than the surface area of the polarizer. In other words, after the press tool contacts the polarizer, the pressure There is a margin L between the single side of the tool and the single side of the polarizer, and the value of the margin L is between 0.5 mm and 1.5 mm. In a specific application, the value of the edge distance L i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com