Upper cover thermal runaway protection mica structural member for new energy automobile and preparation method of upper cover thermal runaway protection mica structural member

A technology for new energy vehicles and structural parts, applied in vehicle parts, electrical components, electrochemical generators, etc., can solve the problems of poor thermal runaway protection performance and durability, achieve excellent and long-lasting thermal runaway protection performance, improve durability and Safety and the effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

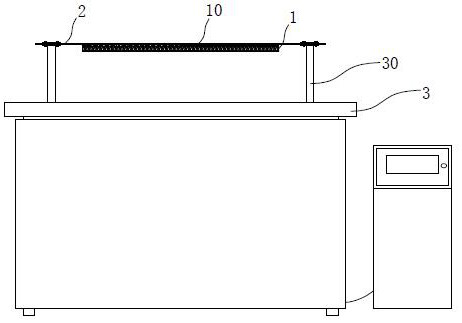

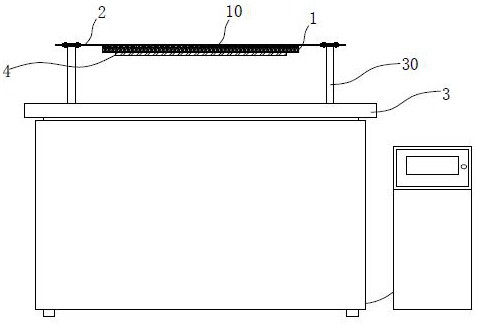

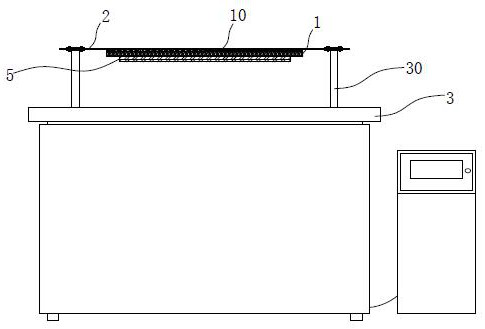

Image

Examples

preparation example 1

[0059] Preparation of synthetic fluorophlogopite aggregates: Put 40-mesh synthetic fluorphlogopite produced by Shijiazhuang Fengming Mineral Products Co., Ltd. in a ball mill, mill at 200 rpm / min for 15 minutes, and use a 300-mesh sieve to sieve to obtain <300 mesh Fluorphlogopite, the retentate of the 300 mesh screen is sub-sieved with a 200 mesh screen to obtain 200-300 order fluorphlogopite, and the retentate of the 200 mesh screen is sub-sieved with a 150 mesh screen to obtain 150- 200 mesh fluorphlogopite, and then the retentate of 150 mesh sieve is sub-sieved with 100 mesh sieve to obtain 100-150 mesh fluorphlogopite. Weigh according to the mass ratio of <300 mesh fluorphlogopite, 200-300 mesh fluorphlogopite, 150-200 mesh fluorphlogopite, 100-150 mesh fluorphlogopite 3:5:20:2, mix to obtain synthetic fluorine gold Mica aggregates.

preparation example 2

[0061] The difference between Preparation Example 2 and Preparation Example 1 is that the mass ratio of <300 mesh fluorphlogopite, 200-300 mesh fluorphlogopite, 150-200 mesh fluorphlogopite, and 100-150 mesh fluorphlogopite is 8:10: 20:5 weighed and mixed to obtain synthetic fluorphlogopite aggregate.

preparation example 3

[0063] The surface-modified fluorophlogopite is prepared from the synthetic fluorophlogopite aggregate in Preparation Example 1 through an electroless aluminum plating process.

[0064] The preparation method of surface modified fluorine phlogopite comprises the following steps:

[0065] Step 1, the preparation of electroless aluminum plating solution, in dry argon vacuum glove box, weigh the anhydrous AlCl of 266.68g 3 (99.9%) and 146.62g of 1-methyl-3-propyl imidazole chloride (EMIC), the temperature was heated to 50°C, and the temperature was maintained between 49.5-50.5°C, and AlCl was gradually added in small amounts while stirring 3 Make it completely melted, then impregnate it with a sufficient amount of 99.99% aluminum wire, and carry out 7 days of replacement and refining at 25°C to obtain a solution for electroless aluminum plating. Take 100mL of solution for electroless aluminum plating in a general-purpose beaker, and control the temperature at 35 ℃, and finally a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com