Waste sludge dewatering method of water-based material

A sludge dewatering, water-based material technology, applied in water/sludge/sewage treatment, sludge treatment, separation methods, etc., can solve the problems of harming people and the environment, poor sealing conditions, poor working environment, etc. High efficiency, improved efficiency, and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

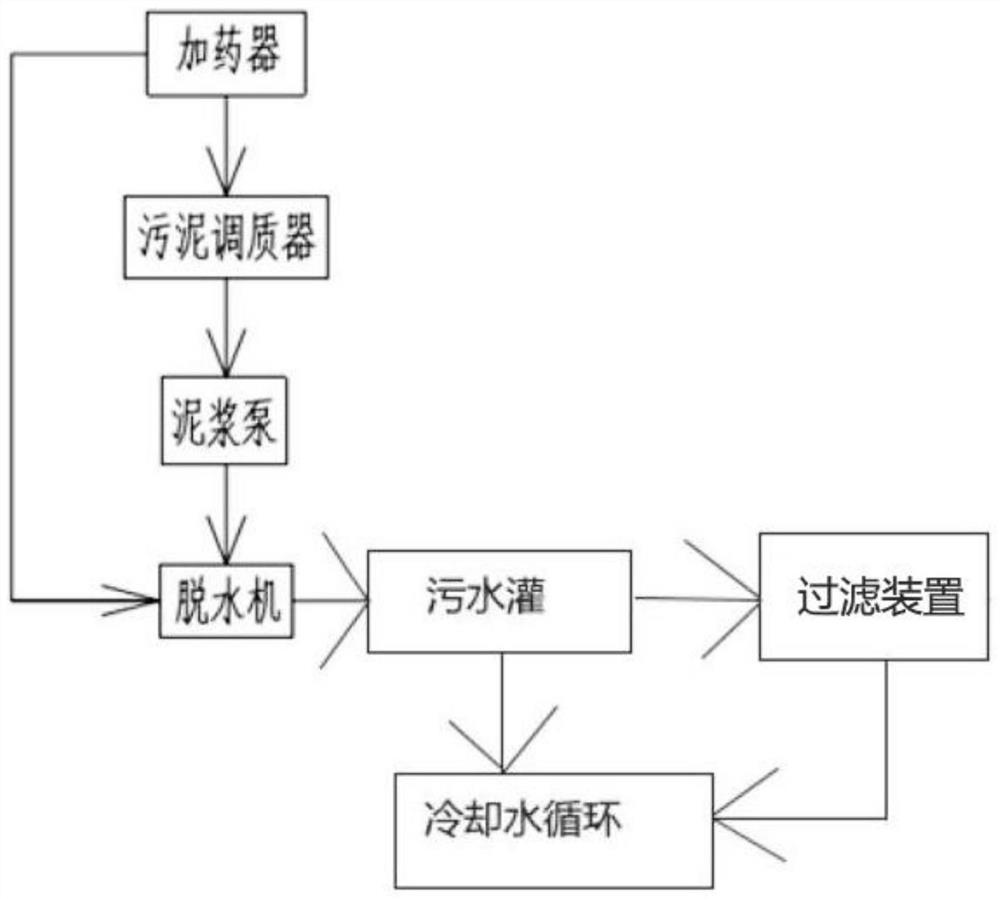

Method used

Image

Examples

Embodiment Construction

[0016] After the applicant's research and analysis, the types of dehydrators commonly used in the prior art include plate-and-frame, centrifugal, belt, and stacked screw. When selecting sludge dewatering equipment, in addition to considering the water content of mud cake, investment Aspects such as cost and operation situation, also need to consider the characteristic of sludge especially, the mercury in the sludge containing mercury just can volatilize a small amount of mercury vapor at normal temperature, and the dehydration device of prior art is usually plate frame type, centrifugal type, The belt-type airtightness is semi-open, and the sealing conditions are not good, and the working environment is poor, which is likely to cause high mercury concentration and secondary pollution. If the management is not good, it will cause mud overflow. If the mercury content in the working space Exceeding the standard will endanger people and the environment. According to these problems...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com