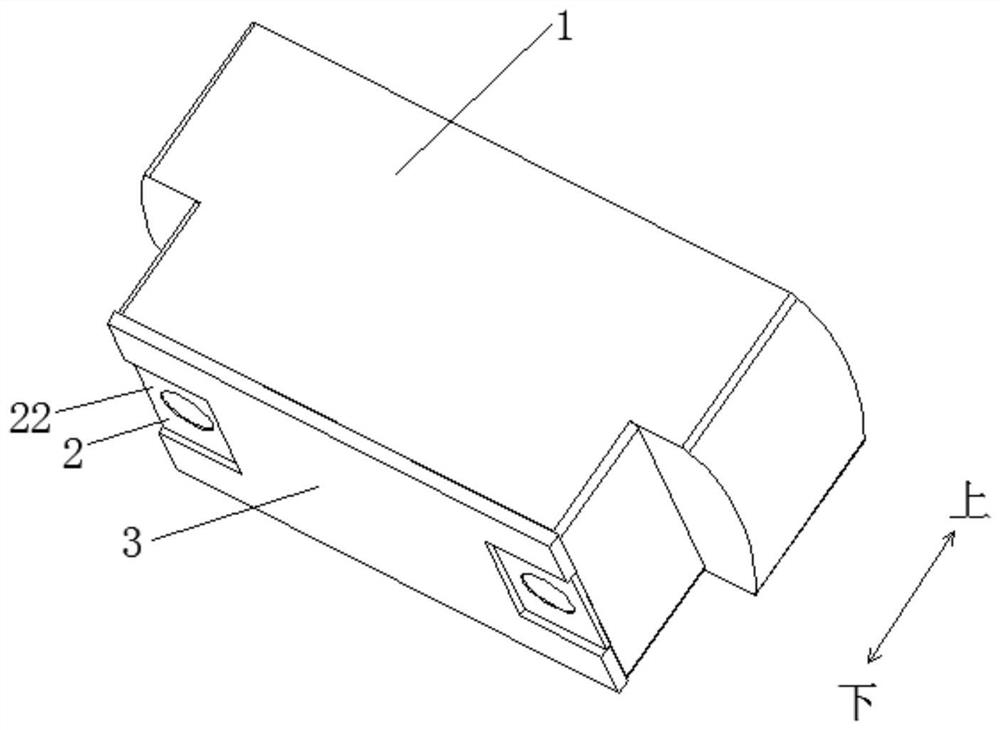

Composition and anti-leakage oil layer and atomizing core thereof

A composition and atomizing core technology, applied in the field of chemical materials, can solve the problems of reduced experience, reduced oil locking ability, oil leakage, etc., and achieve the effect of improving oil leakage prevention ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

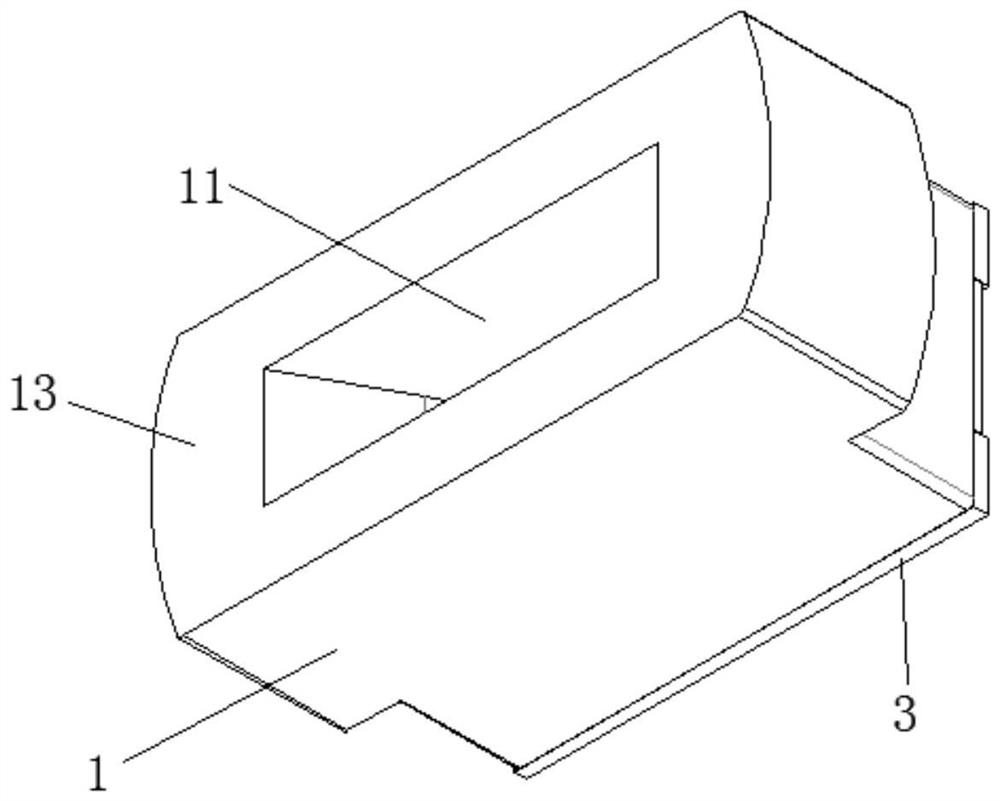

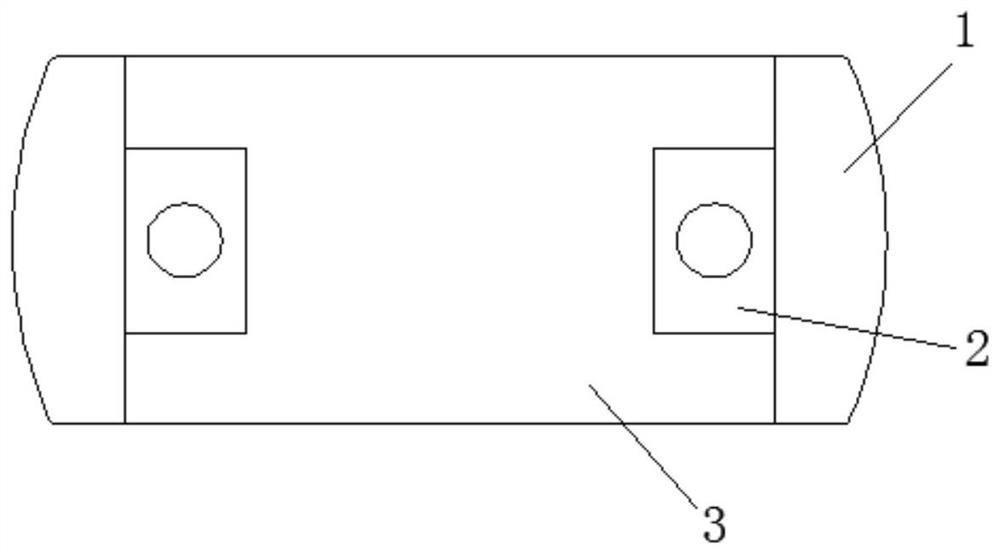

[0080] Weigh each raw material required for preparing the slurry, and the slurry is composed as follows by mass percentage: 25% terpineol, 40% quartz (D50 is 30 μm), 20% softening point is glass powder of 550 ° C, 10% grain Diameter is the pore-forming agent PMMA of 20 microns, 5% resin (by mass percent, the composition of resin is as follows: 50% ethyl cellulose, 20% polyethylene glycol, 10% xylene, 8% oleic acid, 12% polyvinylpyrrolidone, heated and stirred at 60°C). The total mass of the mixed slurry is 100g. After weighing, put all the raw materials into the ball mill tank, the mass ratio of ball to material is 3:1, the diameter of the ball is 8mm, take it out after 300r / min planetary ball mill for 12h, carry out vacuum stirring and defoaming, and finally get the coating slurry. Then, use a 100-mesh screen to print the slurry on the heating surface of the ceramic substrate of the atomizing core (ie, the porous ceramic atomizing core). When designing and printing the scree...

Embodiment 2

[0100] Weigh each raw material required for preparing the slurry, and the slurry is composed as follows by mass percentage: 25% terpineol, 35% quartz (D50 is 30 μm), 20% softening point is glass powder of 550 ° C, 15% grain Pore-forming agent PMMA with a diameter of 20 microns, 2.5% ethyl cellulose, 2% xylene, 0.5% oleic acid. After weighing, put all the raw materials into the ball mill jar, the diameter of the ball is 8mm, the mass ratio of the ball to material is 3:1, take it out after 12 hours of planetary ball milling at 300r / min, carry out vacuum stirring and defoaming, and finally get the coating slurry . Then, use a 100-mesh screen to print the paste on the heating surface of the ceramic substrate of the atomizing core. When designing and printing the screen, ensure that the heating electrode is exposed. The printed heating core was heated at 3°C / min to 600°C for 30 minutes, and then cooled with the furnace to prepare a ceramic atomizing core with an oil-leakage-proof ...

Embodiment 3

[0118] Weigh each raw material required for preparing the slurry, and the slurry is composed as follows by mass percentage: 25% terpineol, 35% quartz (D50 is 30 μm), 20% softening point is glass powder of 550 ° C, 15% grain Pore former PMMA with a diameter of 10 microns, 2.5% ethyl cellulose, 2% xylene, 0.5% oleic acid. After weighing, put all the raw materials into the ball mill jar, the diameter of the ball is 8mm, the mass ratio of the ball to material is 3:1, take it out after 12 hours of planetary ball milling at 300r / min, carry out vacuum stirring and defoaming, and finally get the coating slurry . Then, use a 100-mesh screen to print the paste on the heating surface of the ceramic substrate of the atomizing core. When designing and printing the screen, ensure that the heating electrode is exposed. The printed heating core was heated at 3°C / min to 600°C for 30 minutes and then cooled in the furnace to prepare a ceramic atomizing core with an oil-leakage-proof layer. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com