Method for strengthening carbon-nitrogen conversion in composting process based on magnet particles

A composting and microparticle technology, which is applied in the preparation of organic fertilizers, fertilization devices, organic fertilizers, etc., can solve the problems of poor direct inter-species electron transfer, shorten the time of decomposing, improve the composting process, and shorten the heating and fermentation time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0041] 1. Experiments and methods

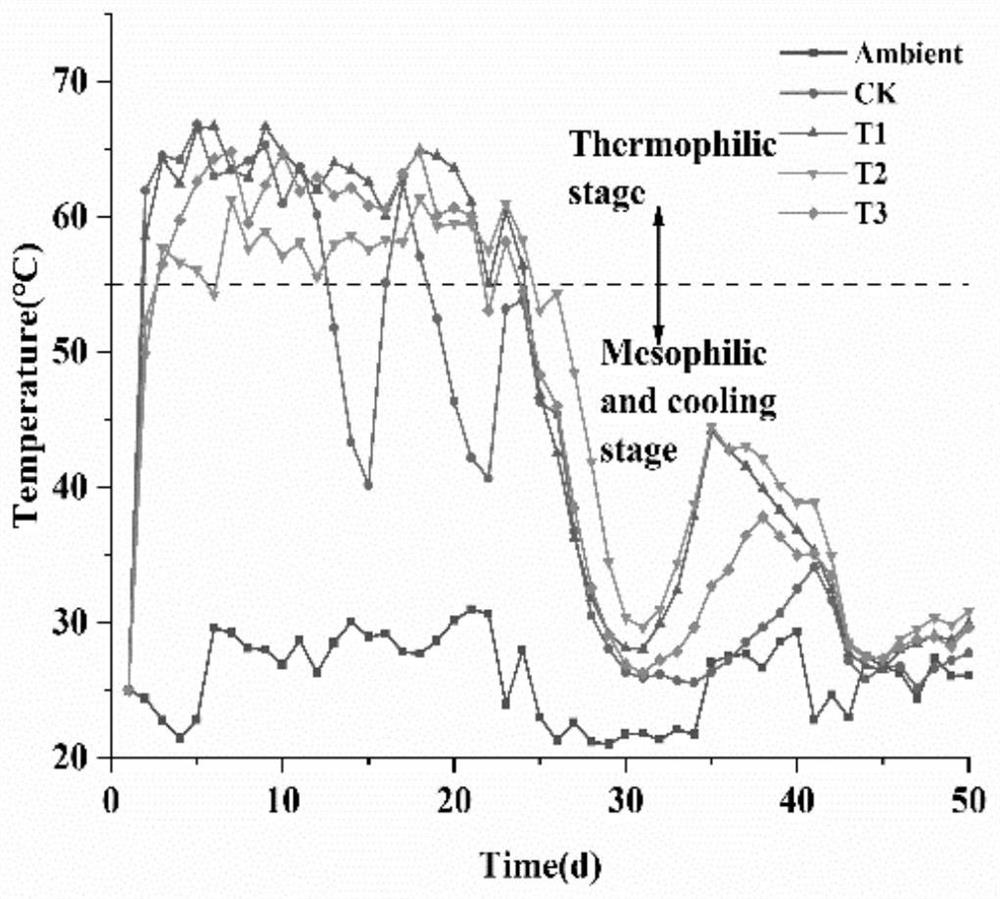

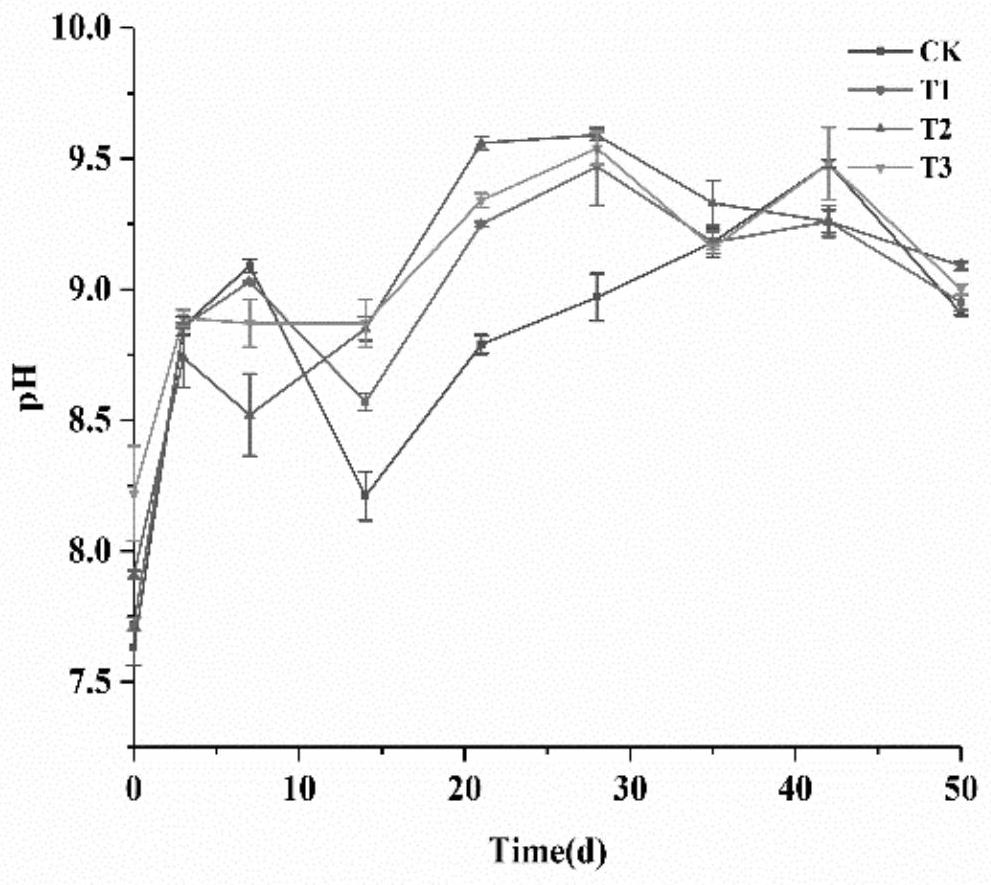

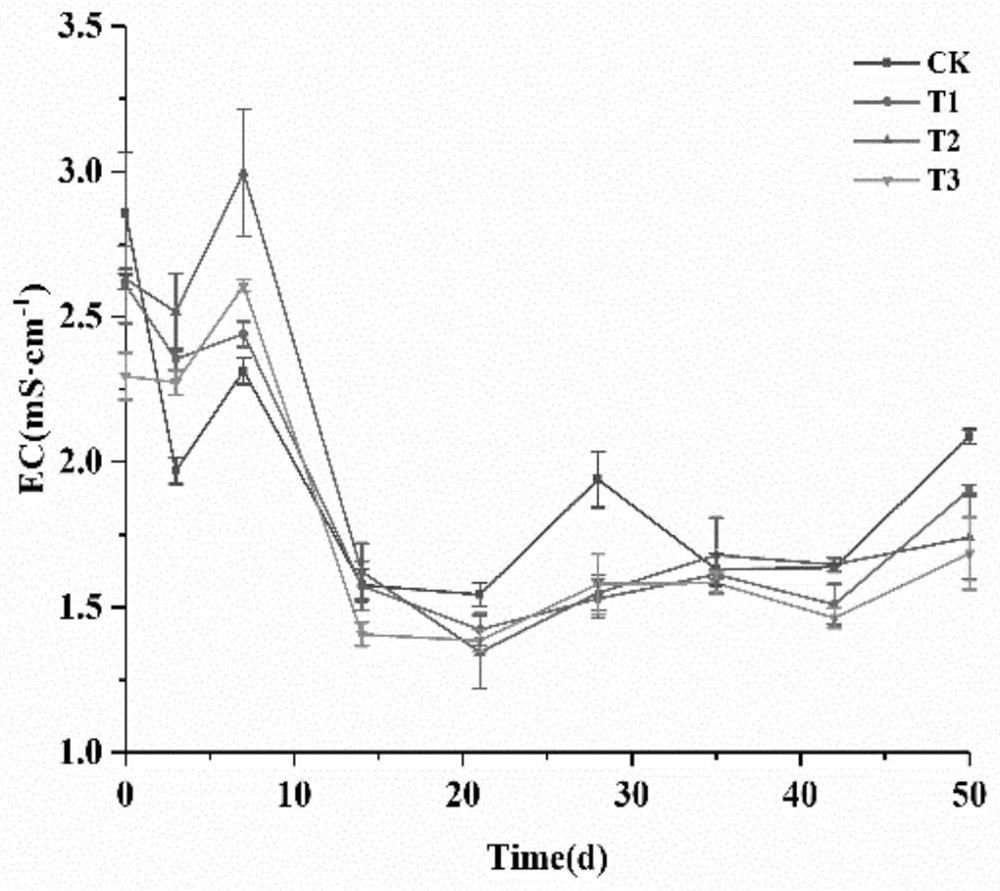

[0042] The materials used for composting are pig manure and wheat straw. The pig manure is selected from local large-scale farms in Yangling, and the wheat straw is purchased from farmers around Yangling. The selected magnet particles are prepared in the laboratory. The specific preparation method is: purchase magnetite from Beijing Yufeng Agriculture and Forestry Technology Co., Ltd., dry it at a constant temperature of 105°C for 6 hours in the laboratory, and use an ultrafine pulverizer to crush it to below 10 microns grade and sieved for later use. Wheat straw is manually chopped to a diameter of <1 cm, mixed with fresh pig manure, and the initial moisture content of the compost is adjusted to 65%, and the initial C / N ratio of the material is adjusted to 25 to ensure the smooth progress of composting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com