Kitchen garbage and sludge co-treatment method based on mesophilic and thermophilic anaerobic co-digestion

A kitchen waste and anaerobic digestion technology, which is applied in the treatment of biological organic parts, climate change adaptation, and the preparation of organic fertilizers, to achieve the effects of reducing process energy consumption, saving facility investment, and high biogas yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

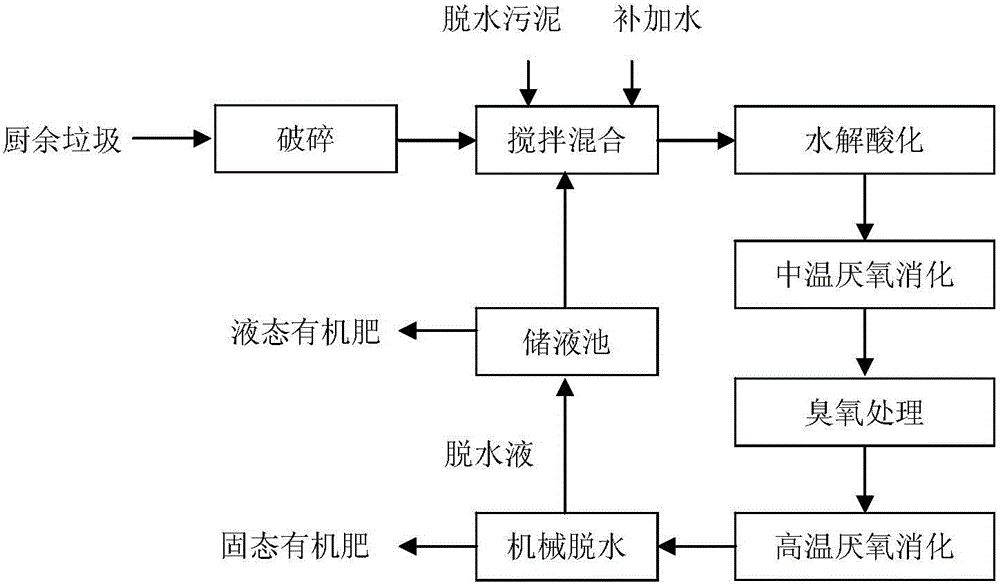

[0030] The joint treatment method of kitchen waste and sludge based on medium and high temperature combined anaerobic digestion, such as figure 1 shown, including the following steps,

[0031] A. Shred the collected kitchen waste, and then transport it to the mixing chamber;

[0032] B. The dewatered sludge with a moisture content of 80% is delivered to the mixing chamber in step A, and the volume of the added dewatered sludge is 0.5 times the volume of kitchen waste in the mixing chamber;

[0033] Stir after injecting water again to obtain a slurried mixed material, and the injection amount of water is to ensure that the water content of the mixed material is 90%;

[0034] C. Transport the mixed material to the hydrolytic acidification tank, and hydrolyze and acidify it for 1 day;

[0035] D. Pump the hydrolyzed and acidified mixed material into the mesophilic anaerobic digestion tank for fermentation treatment. The temperature of the slurry in the mesophilic anaerobic dige...

Embodiment 2

[0040] The joint treatment method of kitchen waste and sludge based on medium and high temperature combined anaerobic digestion, such as figure 1 shown, including the following steps,

[0041] A. Shred the collected kitchen waste, and then transport it to the mixing chamber;

[0042] B. The dewatered sludge with a moisture content of 90% is delivered to the mixing chamber in step A, and the volume of the added dewatered sludge is twice the volume of kitchen waste in the mixing chamber;

[0043] Stir after injecting water again to obtain a slurried mixed material, and the injection amount of water is to ensure that the water content of the mixed material is 95%;

[0044] C. Transport the mixed material to the hydrolytic acidification tank, and hydrolyze and acidify it for 3 days;

[0045] D. Pump the hydrolyzed and acidified mixed material into the mesophilic anaerobic digestion tank for fermentation treatment. The temperature of the slurry in the mesophilic anaerobic digesti...

Embodiment 3

[0051] The joint treatment method of kitchen waste and sludge based on medium and high temperature combined anaerobic digestion, such as figure 1 shown, including the following steps,

[0052] A. Transport the collected kitchen waste to the crushing chamber for crushing treatment, and then transport it to the mixing chamber;

[0053] B. The dewatered sludge with a moisture content of 80-90% is delivered to the mixing chamber in step A, and the volume of the dewatered sludge added is 0.5-2 times the volume of kitchen waste in the mixing chamber;

[0054]After re-injecting water, it is stirred to obtain a slurried mixture, and the injection amount of water is to ensure that the water content of the mixture is 90-95%;

[0055] C. The mixed material is transported to the hydrolysis and acidification tank, and the hydrolysis and acidification treatment is carried out for 1-3 days;

[0056] D. The mixed material that has been hydrolyzed and acidified is pumped into a medium-temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com