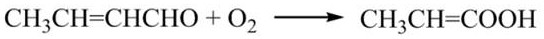

Production method of high-yield transbutylene-2-acid

A high-yield, butene-based technology, applied in chemical instruments and methods, chemical recovery, carboxylate preparation, etc., can solve the problems of unrelated product cis-trans ratio, low yield of butene-2-acid, etc., to achieve Good fluidity, high catalytic activity and selectivity, good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] In the present invention, the preparation method of the supported silver catalyst preferably comprises the following steps:

[0033] impregnating the carrier in a soluble silver salt solution after first roasting to obtain an impregnated product;

[0034] The obtained impregnated product is sequentially dried and secondly calcined to obtain a supported silver catalyst.

[0035] In the present invention, the temperature of the first calcination is preferably 400-900°C, more preferably 500-800°C, and the time of the first calcination is preferably 1-6 h, more preferably 2-5 h; The invention pre-treats the carrier through the first calcination to decompose it into oxides to form the desired structure, and remove the moisture in the carrier, which is conducive to making the active components more uniformly attached to the surface of the carrier. The catalyst is easy to Lost with the solution; after the first roasting is completed, the present invention preferably cools the...

Embodiment 1

[0045] The catalyst used is Ag / TiO 2 Catalyst, the preparation method is co-precipitation method, the specific steps are as follows: 200 gTiO 2 (Anatase type, the specific surface area is about 80 m 2 / g) was roasted at 700 °C for 5 h, after cooling, mixed with 95.7 mL of silver nitrate solution with a concentration of 0.11 g / L, impregnated for 2 h, dried in an oven at 115 °C for 2 h, and then roasted at 450 °C for 4 h , to prepare Ag / TiO with a silver loading of 5% 2 Supported silver catalyst, the particle size is about 150 μm.

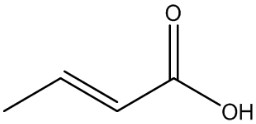

[0046] 70 g butene-2-aldehyde, 140 g ethyl acetate, 1.726 g Ag / TiO 2 The catalyst was added into the autoclave, and reacted with oxygen at room temperature (25 °C), the reaction pressure was 1 MPa, and after 7.8 hours of reaction, the conversion rate of butene-2-aldehyde was 95.73%, and the selectivity of butene-2-acid was 89.09%, the yield was 85.28%, the ratio of trans-butene-2-acid and cis-butene-2-acid in the product was 97:3, and the particl...

Embodiment 2

[0048] The catalyst that present embodiment adopts is Ag / TiO 2 Catalyst, the preparation method is the co-precipitation method, the specific steps are as follows: 200 g TiO 2 (Anatase type, the specific surface area is about 80 m 2 / g) was roasted at 700 °C for 5 h, after cooling, mixed with 95.7 mL of silver nitrate solution with a concentration of 0.11 g / L, impregnated for 2 h, dried in an oven at 115 °C for 2 h, and then roasted at 450 °C for 4 h , to prepare Ag / TiO with a loading of 5% 2 supported silver catalyst.

[0049] 70 g butene-2-aldehyde, 140 g ethyl acetate, 1.726 g Ag / TiO 2 The catalyst was added into the autoclave and reacted with oxygen at 40 °C. The reaction pressure was 1 MPa. After 7 h, the conversion rate of butene-2-aldehyde was 96.53%, the selectivity of butene-2-acid was 92.21%, and the yield is 89.01%, and the ratio of trans-butene-2-acid and cis-butene-2-acid in the product is 97:3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com