Joint production method of lithium difluoro-bis (oxalate) phosphate and lithium difluorophosphate

A technology of lithium difluorodioxalate phosphate and lithium difluorophosphate, which is applied in chemical instruments and methods, phosphorus compounds, phosphorus organic compounds, etc., can solve the problems that it is difficult to use as an additive for non-aqueous electrolyte batteries, and achieve the removal of chloride ions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

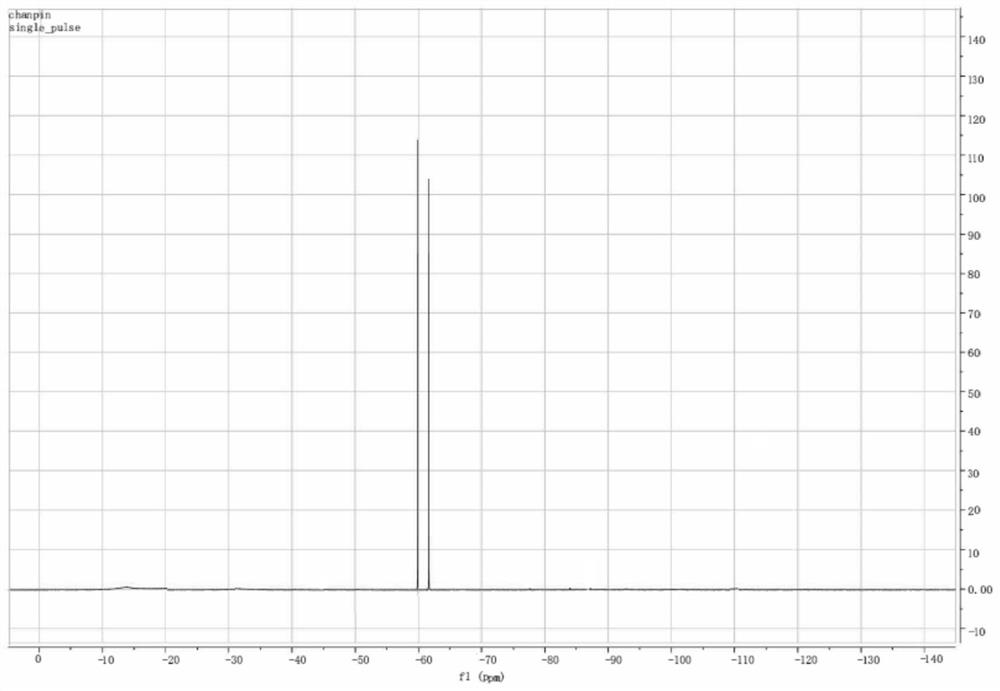

Embodiment 1

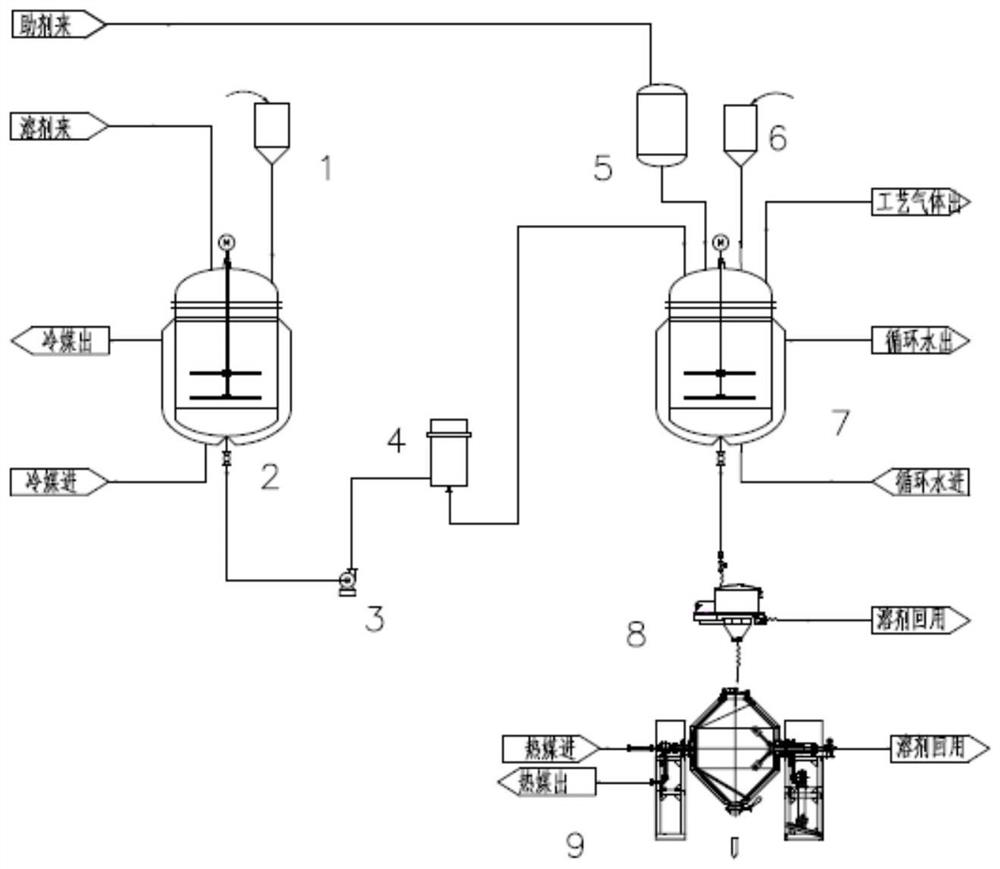

[0039] The method for the preparation of lithium difluorodioxalate phosphate and lithium difluorophosphate and the joint production device of this embodiment comprises the following steps:

[0040] 1) Prepare the following equipment and make devices that meet the requirements: lithium hexafluorophosphate preparation kettle, filter, reaction kettle, centrifuge, double cone drying equipment, etc.;

[0041] 2) dissolving lithium hexafluorophosphate in a carbonate solvent to obtain a lithium hexafluorophosphate solution, adjusting the temperature of the solution to 20° C., after the dissolution is completed, filter through a filter and transfer to a reaction kettle;

[0042] 3) Add oxalic acid to the above-mentioned lithium hexafluorophosphate solution to adjust the temperature of the solution to 20°C, add 10 kg of lithium hexafluorophosphate, the amount of oxalic acid added is based on the molar ratio of oxalic acid and lithium hexafluorophosphate of 1.9:1, gradually add additives...

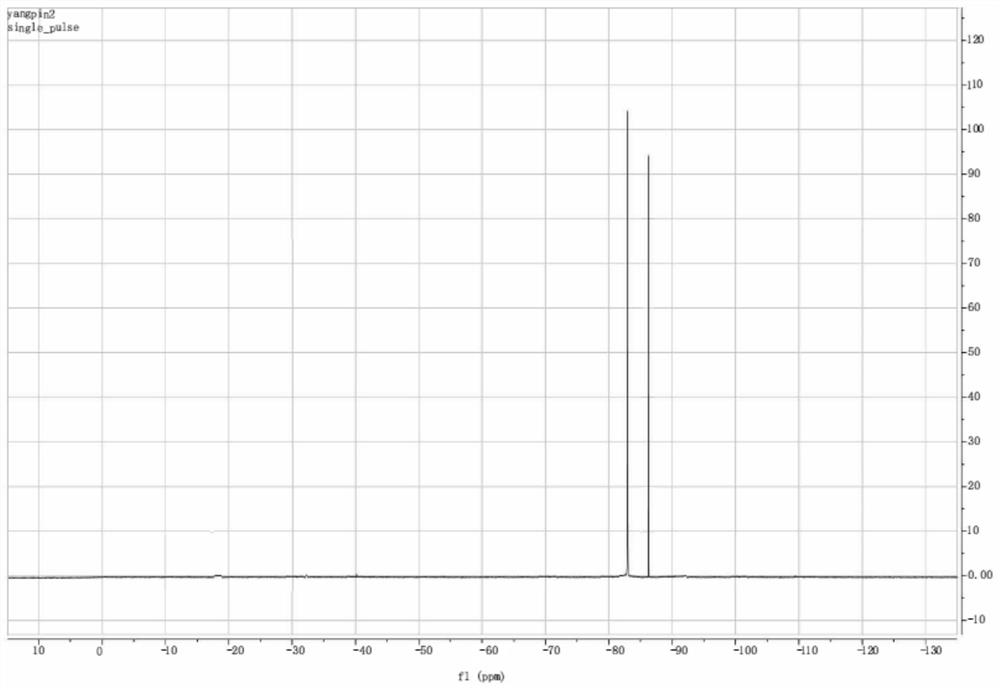

Embodiment 2

[0072] The method for the preparation of lithium difluorodioxalate phosphate and lithium difluorophosphate and the joint production device of this embodiment comprises the following steps:

[0073] 1) Prepare the following equipment and make devices that meet the requirements: lithium hexafluorophosphate preparation kettle, filter, reaction kettle, centrifuge, double cone drying equipment, etc.;

[0074] 2) Dissolving lithium hexafluorophosphate in a carbonate solvent to obtain a lithium hexafluorophosphate solution, adjusting the temperature of the solution to 15° C., after the dissolution is completed, filter through a filter and transfer to a reaction kettle;

[0075] 3) Add oxalic acid to the above-mentioned lithium hexafluorophosphate solution to adjust the temperature of the solution to 15°C, add 10kg of lithium hexafluorophosphate, the amount of oxalic acid added is based on the molar ratio of oxalic acid and lithium hexafluorophosphate of 1.93:1, gradually add additives...

Embodiment 3

[0106] The method for the preparation of lithium difluorodioxalate phosphate and lithium difluorophosphate and the joint production device of this embodiment comprises the following steps:

[0107] 1) Prepare the following equipment and make devices that meet the requirements: lithium hexafluorophosphate preparation kettle, filter, reaction kettle, centrifuge, double cone drying equipment, etc.;

[0108] 2) dissolving lithium hexafluorophosphate in a carbonate solvent to obtain a lithium hexafluorophosphate solution, adjusting the temperature of the solution to 25° C., after the dissolution is completed, filter through a filter and transfer to a reaction kettle;

[0109] 3) Add oxalic acid to the above lithium hexafluorophosphate solution to adjust the temperature of the solution to 25°C, add 10kg of lithium hexafluorophosphate, the amount of oxalic acid added is based on the molar ratio of oxalic acid and lithium hexafluorophosphate of 1.96:1, gradually add additives for react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com