Compressed air energy storage system adopting high-pressure high-temperature hot water for heat storage and operation method of compressed air energy storage system

A technology of compressed air energy storage, high pressure and high temperature, applied in heat storage equipment, indirect heat exchangers, heat exchanger types, etc. Low problems, to achieve the effect of taking into account investment and power station efficiency, long system life and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

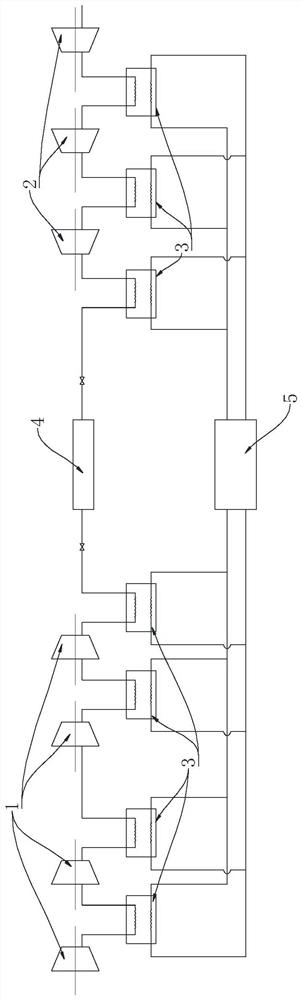

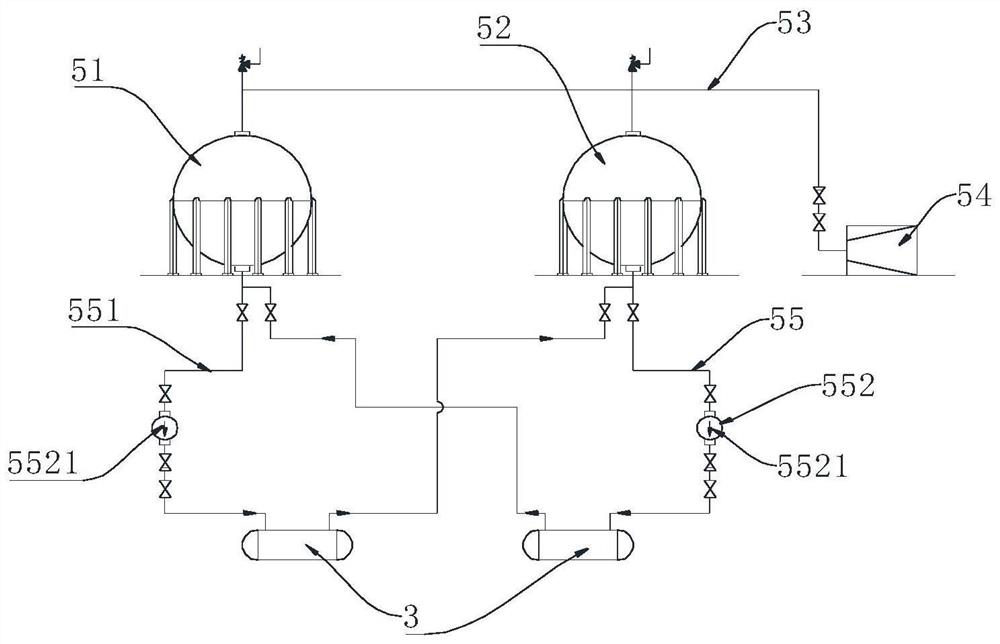

[0049] Such as figure 1 As shown, this embodiment provides a compressed air energy storage system using high-pressure and high-temperature hot water heat storage. The compressed air energy storage system includes a compressor 1, an expander 2, a heat exchanger 3, an air storage system 4 and a high-temperature The hot water heat storage and release system 5, the present invention adopts a multi-stage compression system and a multi-stage expansion system, that is, the present embodiment preferably adopts 4 compressors 1 and 3 expanders 2, wherein, the 4 compressors 1 are sequentially connected in series with The 4 inlets of the gas storage system are connected, and a heat exchanger 3 is connected to the outlet of each compressor 1; the 3 expanders 2 are connected in series with the 4 outlets of the gas storage system, and a heat exchanger 3 is connected to the inlet of each expander 2 heat exchanger 3. The high-temperature hot water heat storage and release system 5 is used to ...

Embodiment 2

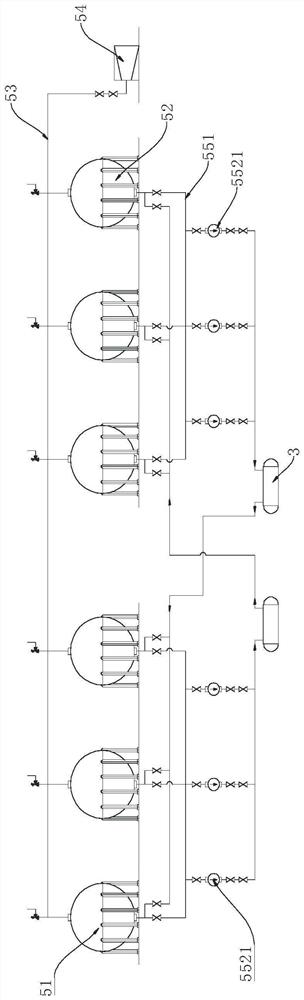

[0067] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the high-temperature hot water storage and release system 5 of this embodiment is provided with three hot water storage tanks 51 and three cold water storage tanks 52, and the hot water storage tanks 51 and three cold water storage tanks are appropriately increased. The number of cold water storage tanks 52 can increase the energy storage and heat storage capacity of the system as a whole, and improve the energy storage and heat storage efficiency. Specifically, in order to supply the water transfer volume between the three hot water storage tanks 51 and the three cold water storage tanks 52, three one-way water pumps 5521 are arranged on each group of water transfer pipes 551 to improve the water transfer efficiency, that is, each The hot water storage tank 51 and each cold water storage tank 52 are respectively provided with a one-way water pump 5521 correspondingly.

Embodiment 3

[0069] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the high-temperature hot water heat storage and release system 5 of this embodiment is only provided with a set of water delivery system 55. Specifically, the water pump 552 in this embodiment adopts a bidirectional water pump 5522, whose It can be used to pump water from the hot water storage tank 51 to the cold water storage tank 52 through the heat exchanger 3 through the water delivery pipe 551 and to pump water from the cold water storage tank 52 to the hot water storage tank 51 through the heat exchanger 3, and the direction of water delivery can be switched.

[0070] Such as Figure 5 As shown, correspondingly, the compressor 1 and the expander 2 in the compressed air energy storage system of this embodiment are connected in parallel and share a set of heat exchangers 3, that is, when the compressor 1 is working, the inlet and outlet of the expander 2 are closed; When mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com