Flexible pressure sensor based on double-sided engraved laser-induced graphene

A pressure sensor and laser-induced technology, applied in the fluid pressure measurement, instrument, and force measurement using capacitance change, can solve the problems of time-consuming, labor-intensive, and expensive preparation, and achieve the effects of excellent device performance, guaranteed sensitivity, and reduced cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

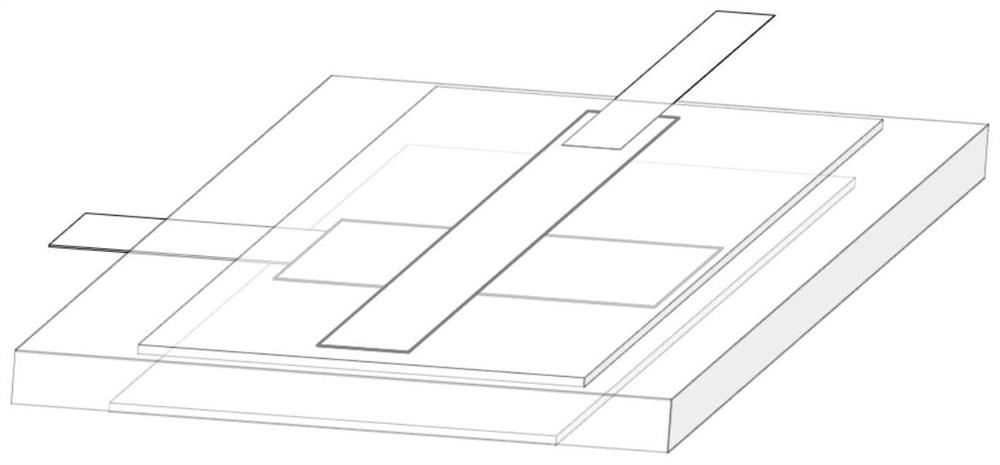

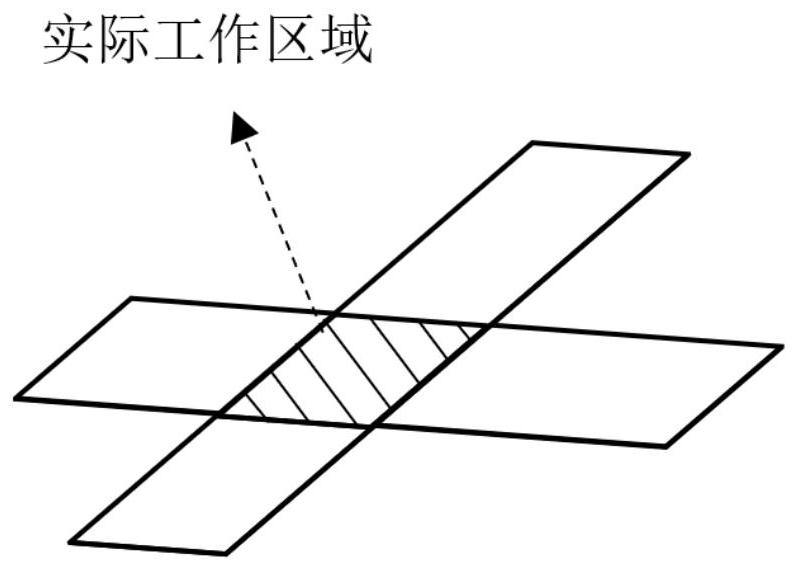

[0026] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

[0027] The carbon precursor materials used for laser processing mentioned in the present invention include but are not limited to polyimide, and the polyimide thin paper used in this example is a preferred material after comparison, including but not limited to For polyimide thin paper and film of different thickness.

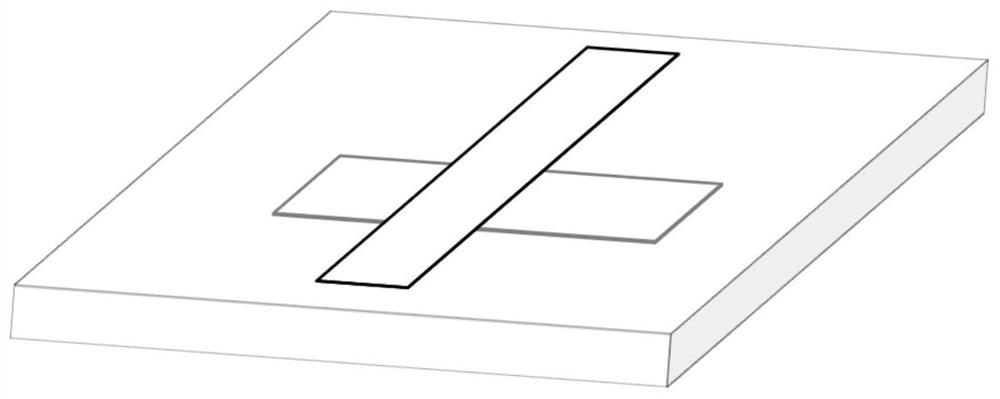

[0028] In this embodiment, the PI paper is cut into a suitable size, and 14 mm×14 mm is preferably used as the substrate material size of the processing electrode from the dimensions of 5 mm×5 mm to 20 mm×20 mm. Use adhesive tape to fix the cut PI paper on the inner bottom plate of the laser, and set the optimal laser processing parameters to laser engrave the surface of the PI paper to form graphene upper electrode patterns.

[0029] The maximum laser power of the semiconductor laser used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com