Electronic brake implementation method based on d-axis current controller and servo driver thereof

A servo drive, electronic braking technology, applied in the direction of controlling electromechanical brakes, controlling electromechanical transmission devices, controlling generators, etc., can solve problems such as unfavorable product maintenance, high maintenance and repair costs, and easily damaged braking resistors, and achieve convenient product maintenance. The effect of maintenance and reduction of product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

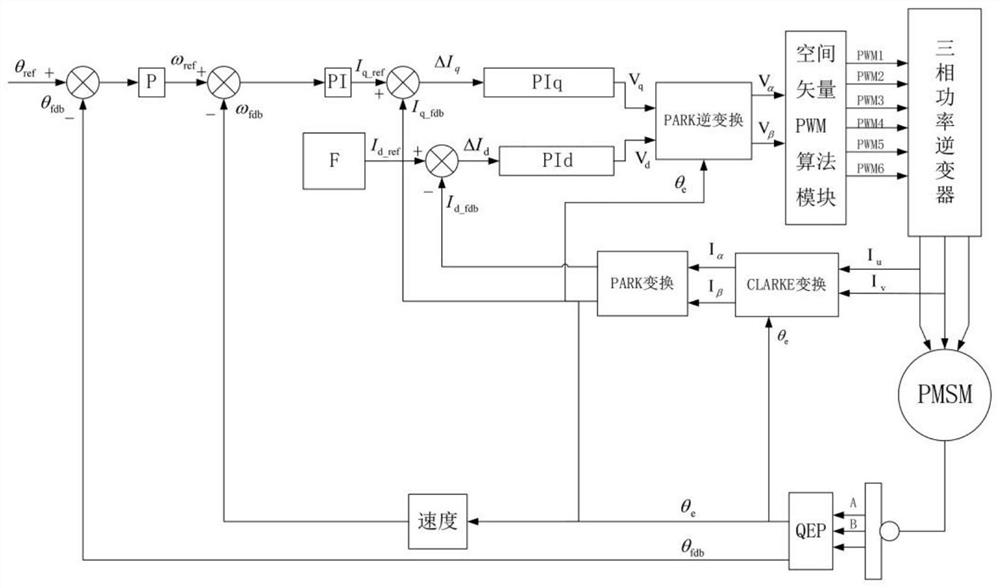

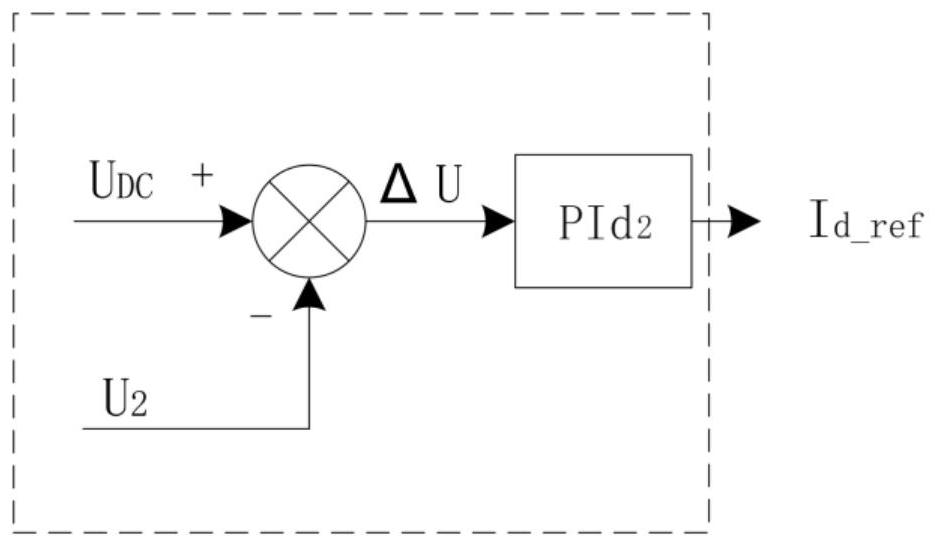

[0033] The solution provides a servo driver capable of realizing the electronic braking function based on the d-axis current controller, and the electronic braking function based on the d-axis current controller realized by the servo driver.

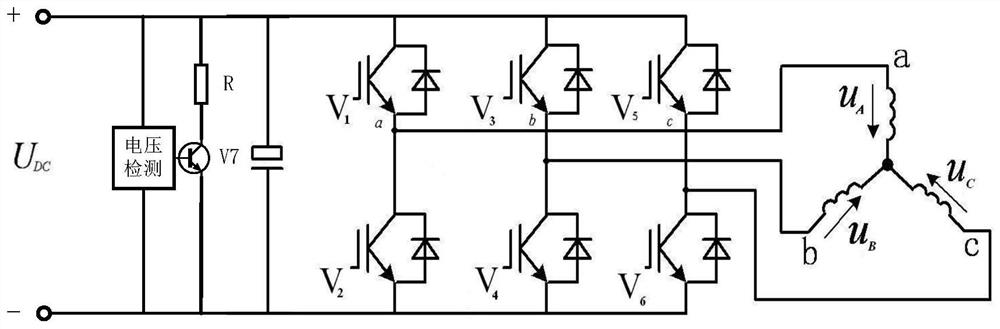

[0034] This scheme is realized by using the vector control of the servo driver, borrowing the existing vector control process of the servo driver, and changing the bus voltage U related to the brake on the basis of the vector control DC The vector control process is added to realize software braking, so that the energy generated by the motor braking can be converted into the copper loss and iron loss of the motor through the d-axis current. There is no need to install additional braking circuits, which improves the efficiency while reducing costs. System maintainability.

[0035] Such as figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com