Method for synthesizing titanium-aluminum binary oxide catalyst by sol-gel method

A binary oxide, sol-gel technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of low catalytic efficiency, complex catalyst synthesis, high cost, and achieve high Catalytic efficiency, the effect of improving catalytic efficiency and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

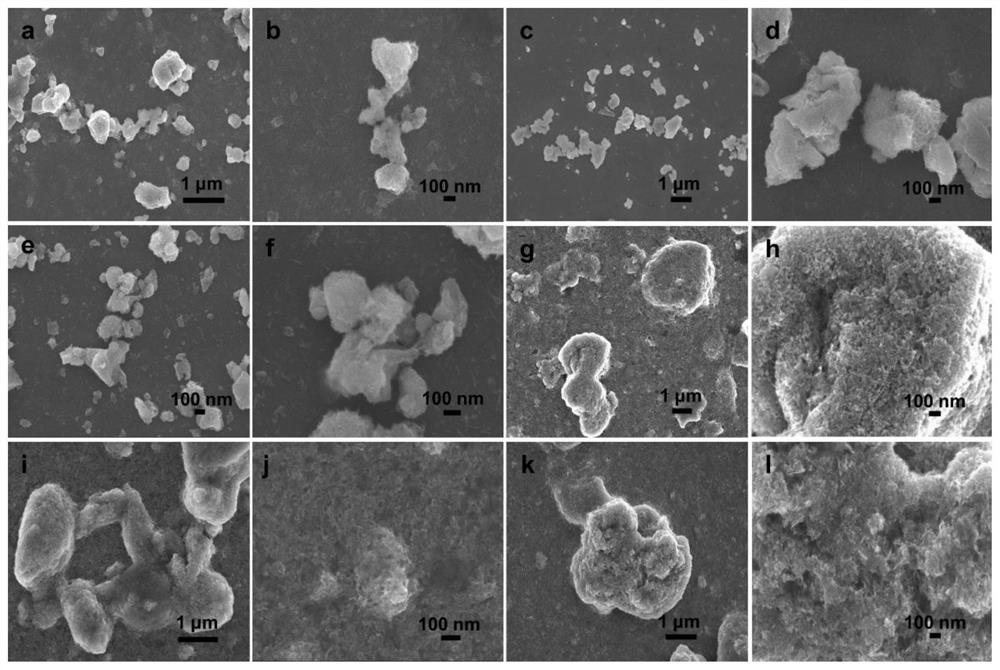

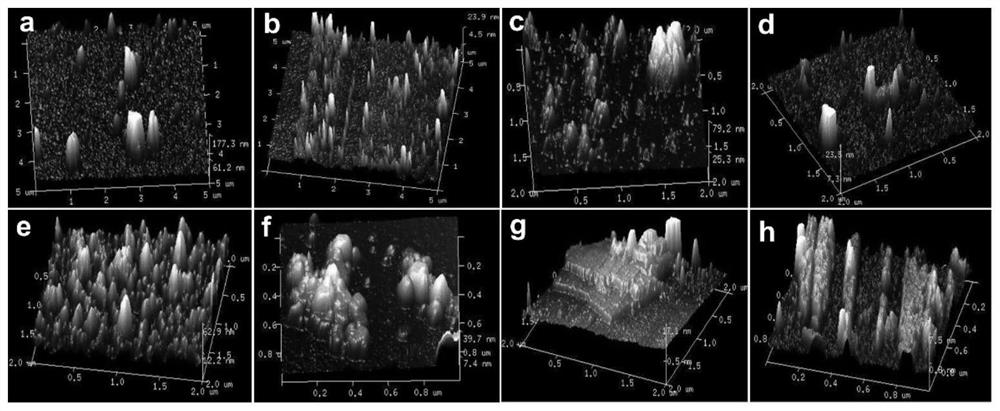

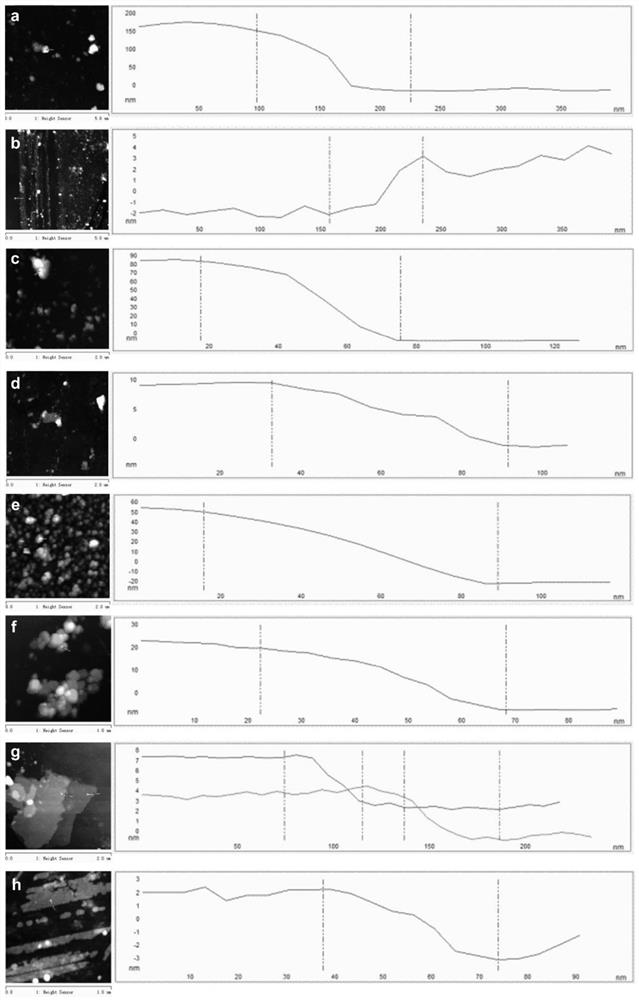

Image

Examples

Embodiment 1

[0041] 1) Dissolve 0.8 g of PVP in 30 ml of distilled water, and add Ti (OBU) according to 1: 1 molar ratio. 4 And Al (no 3 ) 3 · 9h 2 O, stir it for 5 min, then add 2.5 mmol nabh 4 , Stirred at 25 ° C for 2 h;

[0042] 2) Transfer the above mixture to the reactor, 100 ° C reaction for 24 hours, then naturally cooled to obtain a mixture;

[0043] 3) Collecting the above mixed liquid, washed with ethanol (3 × 3 mL) and distilled water (3 × 3 mL), dried in air at 60 ° C for 12 h, to give a titanium-aluminum diazo-aluminum di-aluminum-aluminum oxide white solid powder 0.13g, remembered C1.

Embodiment 2

[0045] 1) Dissolve 0.8 g of PVP in 30 ml of distilled water, and add Ti (OBU) according to 1: 1 molar ratio. 4 And Al (no 3 ) 3 · 9h 2 O, stir it for 5 minutes, then add 2.5mmol NH 3 · H 2 O, stirred at 25 ° C for 2 h;

[0046] 2) Transfer the above mixture to the reactor, 100 ° C reaction for 24 hours, then naturally cooled to obtain a mixture;

[0047] 3) Collecting the above mixture, washed with ethanol (3 × 3 mL) and distilled water (3 × 3 mL), dried in air at 60 ° C for 12 h, to give a titanium-aluminum diazo-aluminum oxide white solid powder 0.11g, recorded C2.

Embodiment 3

[0049] 1) Take 30ml distilled water, and add Ti (OBU) to the molar ratio of 1: 1. 4 And Al (no 3 ) 3 · 9h 2 O, stir it for 5 minutes, then add 2.5mmol NH 3 · H 2 O, stirred at 25 ° C for 2 h;

[0050] 2) Transfer the above mixture to the reactor, 100 ° C reaction for 24 hours, then naturally cooled to obtain a mixture;

[0051] 3) The above mixture was centrifuged, washed with ethanol (3 × 3 mL) and distilled water (3 × 3 mL), dried in air at 60 ° C for 12 h to give a titanium-aluminum diazo oxide white solid powder 0.10g, remembered C3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com