A nanorod-shaped non-metal doped bipo 4 Photocatalyst and its preparation method and application

A photocatalyst, nanorod-like technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., to achieve the effects of short preparation cycle, high photocatalytic activity, and simple and controllable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

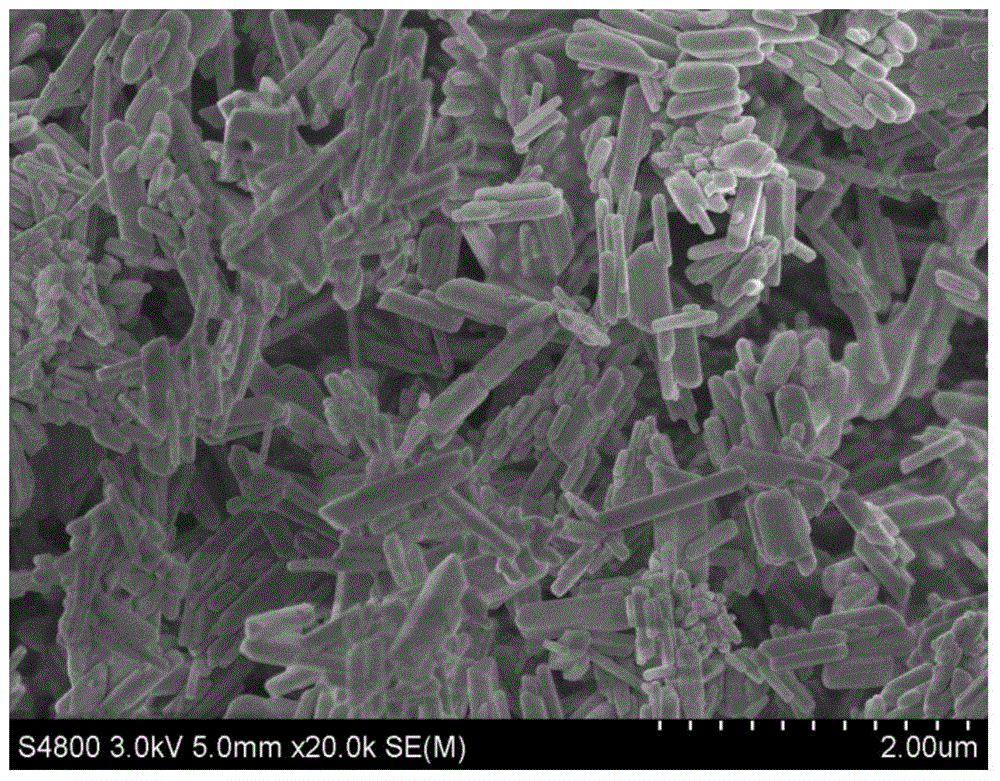

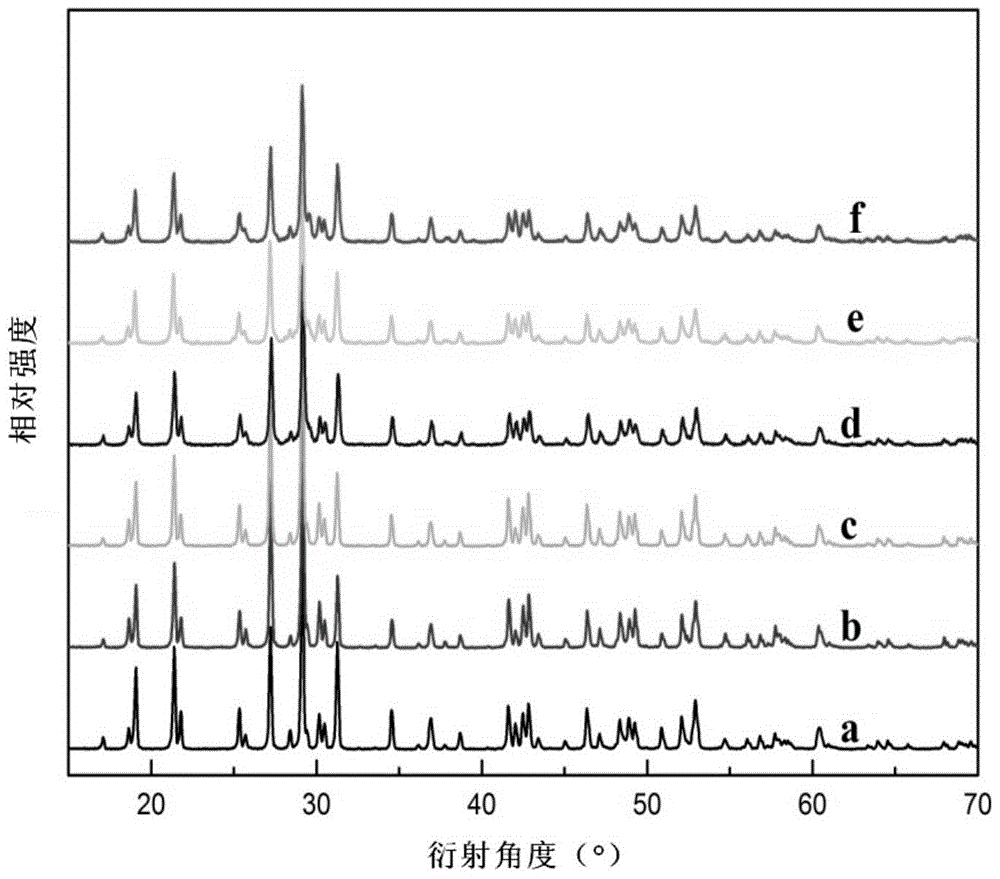

Embodiment 1

[0036] Step 1: Na 3 PO 4 12H 2 O was dissolved in water, and then C was added according to the molar ratio of C and Bi of 7.5:100 6 h 12 o 6 and Bi(NO 3 ) 3 ·5H 2 O, then add dilute nitric acid with a concentration of 1mol / L, and stir magnetically for 30 minutes until the mixture is uniform to form a precursor, wherein n C +n Bi =n P (The sum of the amount of substance of Bi element and the amount of substance of C element is equal to the amount of substance of P element), the volume ratio of water and dilute nitric acid is 46.5:3.5; Na in the precursor 3 PO 4 12H 2 The concentration of O is 0.06mol / L;

[0037] Step 2: Put the precursor into a polytetrafluoroethylene-lined microwave hydrothermal reactor, control the filling ratio of the microwave hydrothermal reactor to 50%, put the microwave hydrothermal reactor into the microwave hydrothermal instrument, select Microwave temperature control mode: set the microwave power to 300W, raise the temperature from room t...

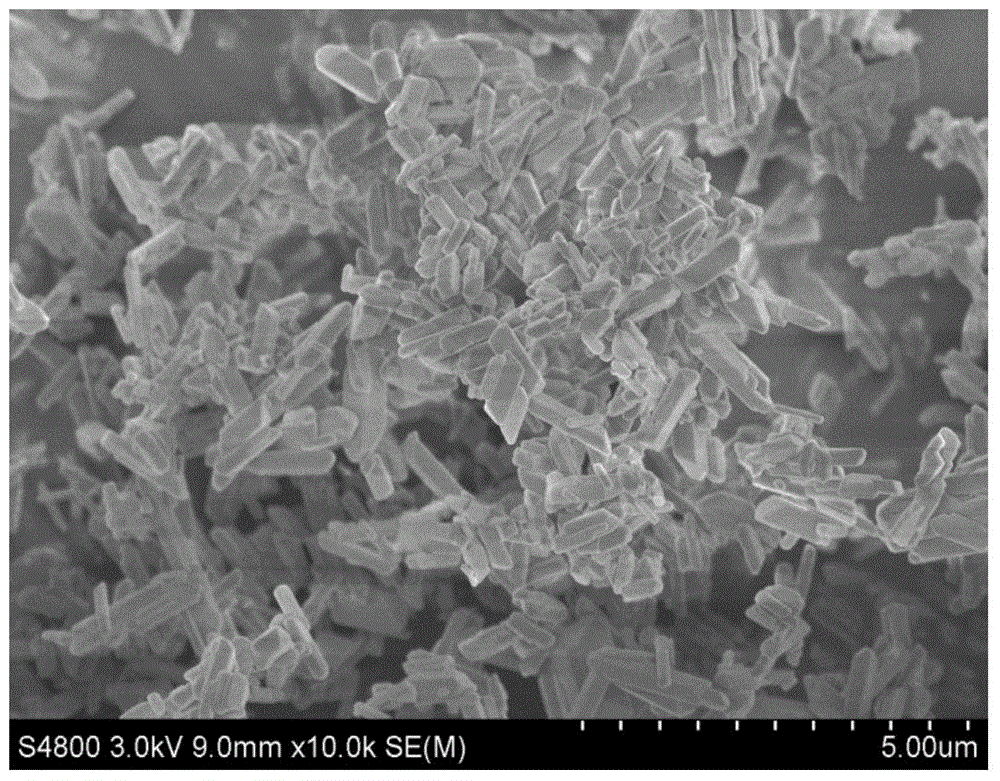

Embodiment 2

[0039] Step 1: Na 3 PO 4 12H 2 O was dissolved in water, and then C was added according to the molar ratio of C and Bi of 17.6:100 6 h 12 o 6 and Bi(NO 3 ) 3 ·5H 2 O, then add dilute nitric acid with a concentration of 1mol / L, and stir magnetically for 30 minutes until the mixture is uniform to form a precursor, wherein n C +n Bi =n P (the sum of the amount of substance of Bi element and the amount of substance of C element is equal to the amount of substance of P element), the volume ratio of water and dilute nitric acid is 46.5:3.5; Na in the precursor 3 PO 4 12H 2 The concentration of O is 0.06mol / L;

[0040] Step 2: Put the precursor into a polytetrafluoroethylene-lined microwave hydrothermal reactor, control the filling ratio of the microwave hydrothermal reactor to 50%, put the microwave hydrothermal reactor into the microwave hydrothermal instrument, select Microwave temperature control mode: set the microwave power to 300W, raise the temperature from room ...

Embodiment 3

[0042] Step 1: Na 3 PO 4 12H 2 O was dissolved in water, and then C was added according to the molar ratio of C and Bi of 37:100 6 h 12 o 6 and Bi(NO 3 ) 3 ·5H 2 O, then add dilute nitric acid with a concentration of 1mol / L, and stir magnetically for 30 minutes until the mixture is uniform to form a precursor, wherein n C +n Bi =n P (the sum of the amount of substance of Bi element and the amount of substance of C element is equal to the amount of substance of P element), the volume ratio of water and dilute nitric acid is 46.5:3.5; Na in the precursor 3 PO 4 12H 2 The concentration of O is 0.06mol / L;

[0043] Step 2: Put the precursor into a polytetrafluoroethylene-lined microwave hydrothermal reactor, control the filling ratio of the microwave hydrothermal reactor to 50%, put the microwave hydrothermal reactor into the microwave hydrothermal instrument, select Microwave temperature control mode: set the microwave power to 300W, raise the temperature from room te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com