Preparation method of stone powder exciting agent

A technology of activator and stone powder, which is applied in the field of preparation of stone powder activator, can solve the problems of single product, difficulty in effectively improving the activity of cement compound, affecting the proportion of cement compound contained in the strength of the cement compound, etc., and achieve particle roundness The effect of increasing the coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

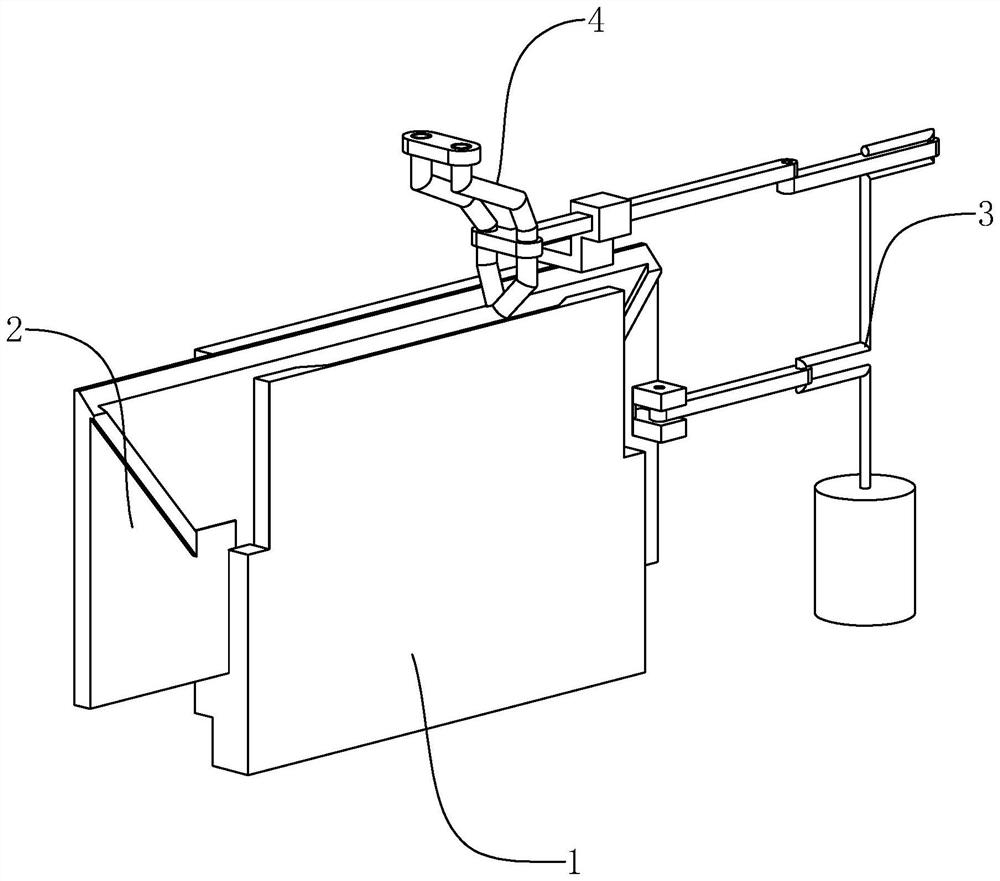

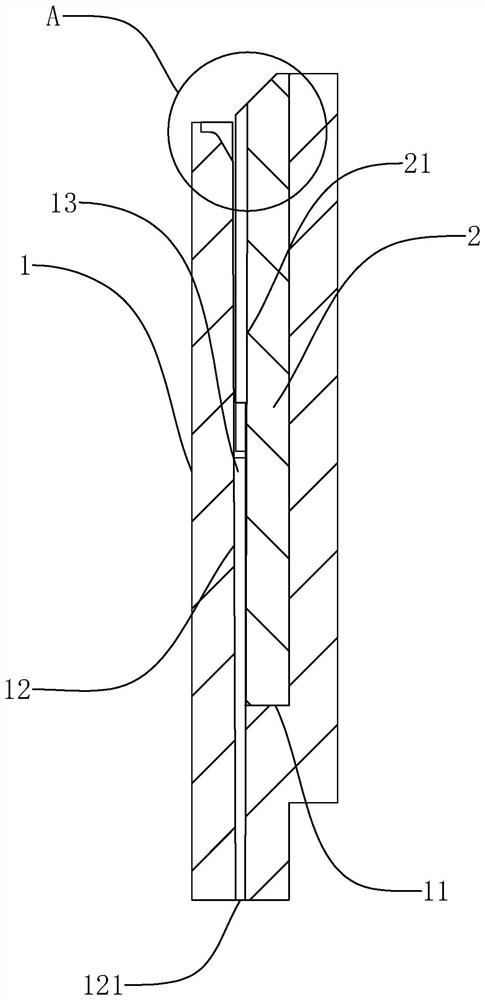

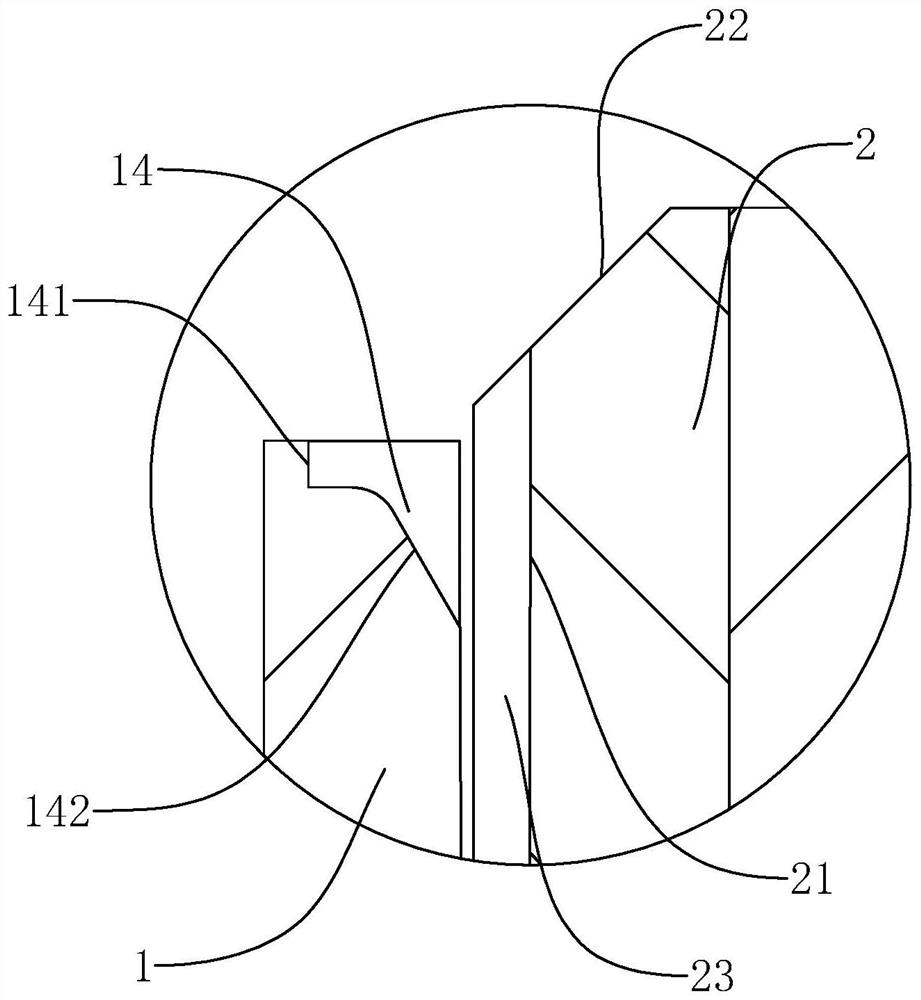

Method used

Image

Examples

Embodiment 1

[0040] A preparation method of a stone powder activator, comprising the steps of:

[0041] Step 1, get the marble stone powder that is 92.2 parts by weight as a mixture one and be respectively 3.05 parts of sodium thiosulfate, 1.71 parts of sodium bisulfite, 0.70 parts of sodium silicate, 0.39 parts of hydrogen Alumina and 0.25 parts of hollow glass microspheres are mixed and used as mixing material 2;

[0042] Step 2. Put the mixture 1 into the grinder and grind it, and dry it while grinding to obtain the grinding material 1 with a specific surface area ≥ 320m2 / kg; put the mixture 2 into the mixer, and mix it under stirring Simultaneously dry treatment, obtain compound one;

[0043] Step 3. Import the grinding material 1 and the mixture 1 into the friction bonding machine in proportion, and introduce them into the stirring mixer at the bottom of the friction bonding machine under the double action of horizontal friction and gravity for stirring, and obtain the finished stone...

Embodiment 2

[0052] A preparation method of a stone powder activator, comprising the steps of:

[0053] Step 1, get the granite stone powder that is 86.4 parts by weight as a mixture one and 3.22 parts by weight of sodium thiosulfate, 1.83 parts of sodium bisulfite, 0.75 parts of sodium silicate, 0.41 parts of hydrogen Aluminum oxide and 0.28 parts of hollow glass microspheres are mixed and used as mixing material 2;

[0054] Step 2. Put the mixture 1 into the grinder and grind it, and dry it while grinding to obtain the grinding material 1 with a specific surface area ≥ 320m2 / kg; put the mixture 2 into the mixer, and mix it under stirring Simultaneously dry treatment, obtain compound one;

[0055] Step 3. Import the grinding material 1 and the mixture 1 into the friction bonding machine in proportion, and introduce them into the stirring mixer at the bottom of the friction bonding machine under the double action of horizontal friction and gravity for stirring, and obtain the finished sto...

Embodiment 3

[0058] A preparation method of a stone powder activator, comprising the steps of:

[0059] Step 1, get the granite stone powder that is 96.6 parts by weight as mixture one and be respectively the sodium thiosulfate of 2.86 parts, the sodium bisulfite of 1.62 parts, the sodium silicate of 0.66 parts, the hydrogen of 0.37 parts by weight Alumina and 0.22 parts of hollow glass microspheres are mixed and used as mixing material 2;

[0060] Step 2. Put the mixture 1 into the grinder and grind it, and dry it while grinding to obtain the grinding material 1 with a specific surface area ≥ 320m2 / kg; put the mixture 2 into the mixer, and mix it under stirring Simultaneously dry treatment, obtain compound one;

[0061] Step 3. Import the grinding material 1 and the mixture 1 into the friction bonding machine in proportion, and introduce them into the stirring mixer at the bottom of the friction bonding machine under the double action of horizontal friction and gravity for stirring, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com