Composite alkali-activated lithium slag low-temperature early-strength concrete and preparation method thereof

A technology of concrete and compound alkali, which is applied in the field of building materials, can solve the problems of reduced concrete section and reduced concrete strength, and achieve the effects of promoting early strength, improving early strength, and high grindability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

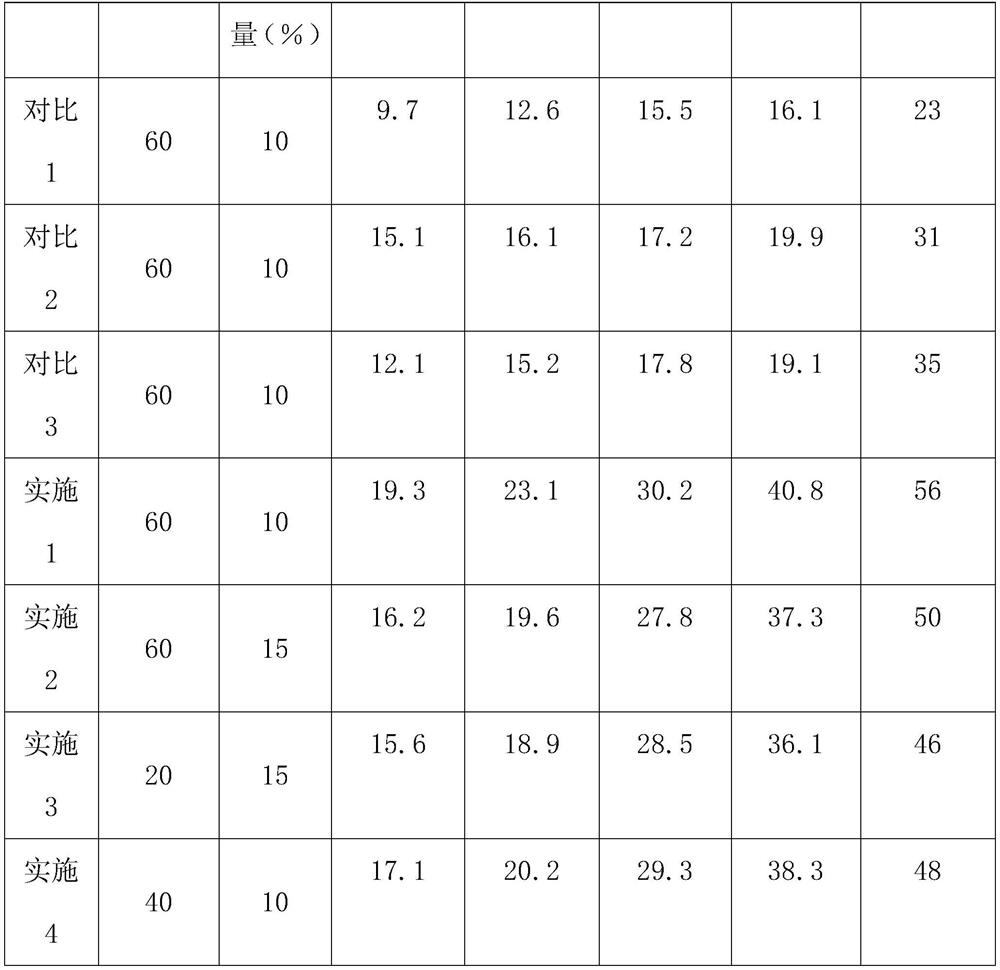

Examples

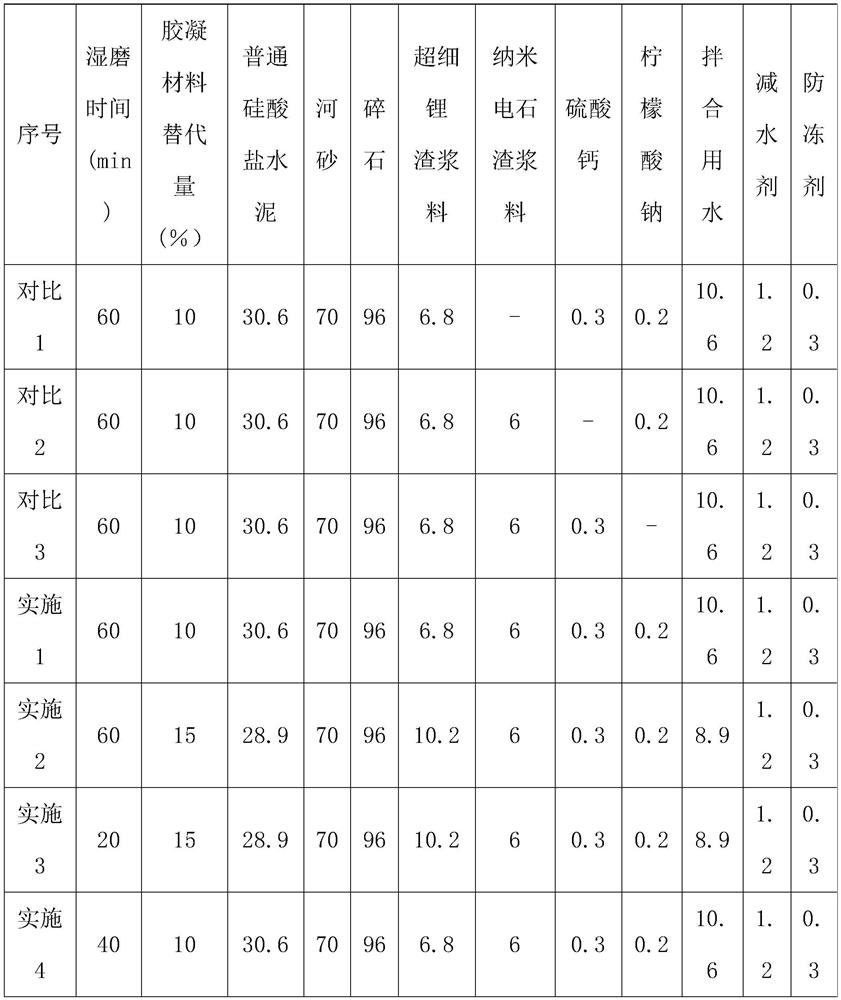

Embodiment 1

[0049] The method for preparing low-temperature early-strength concrete by compound alkali stimulating lithium slag comprises the following steps:

[0050] Step 1: Lithium slag, carbide slag are carried out dry grinding 15-30min respectively, obtain 20-25 μm lithium slag powder and carbide slag powder by sieving;

[0051] Step 2: Get 3.4 parts of lithium slag powder and 3.4 parts of water and mix them with wet milling for 60 minutes to obtain 6.8 parts of ultrafine lithium slag slurry;

[0052] Step 3: get 2 parts of calcium carbide slag powder, 4 parts of water and mix and then wet mill for 60 minutes to obtain 6 parts of nano carbide slag slurry;

[0053] Step 4: Take 6.8 parts of ultrafine lithium slag slurry, 6 parts of nano carbide slag slurry, 30.6 parts of cement, 0.3 part of calcium sulfate, 0.2 part of sodium citrate, 70 parts of river sand, and 96 parts of crushed slag obtained in steps 2 and 3. Stone, 10.6 parts of mixing water, 1.2 parts of water reducer, 0.3 part...

Embodiment 2

[0056] The method for preparing low-temperature early-strength concrete by compound alkali stimulating lithium slag comprises the following steps:

[0057] Step 1: Lithium slag, carbide slag are carried out dry grinding 15-30min respectively, obtain 20-25 μm lithium slag powder and carbide slag powder by sieving;

[0058] Step 2: Get 5.1 parts of lithium slag powder and 5.1 parts of water after mixing and wet mill for 60 minutes to obtain 10.2 parts of ultrafine lithium slag slurry;

[0059] Step 3: get 2 parts of calcium carbide slag powder, 4 parts of water and mix and then wet mill for 60 minutes to obtain 6 parts of nano carbide slag slurry;

[0060] Step 4: Take 10.2 parts of ultrafine lithium slag slurry, 6 parts of nano carbide slag slurry and 28.9 parts of cement, 0.3 part of calcium sulfate, 0.2 part of sodium citrate, 70 parts of river sand, and 96 parts of crushed slag obtained in steps 2 and 3. Stone, 8.9 parts of mixing water, 1.2 parts of water reducer, 0.3 part...

Embodiment 3

[0063] The method for preparing low-temperature early-strength concrete by compound alkali stimulating lithium slag comprises the following steps:

[0064] Step 1: Lithium slag, carbide slag are carried out dry grinding 15-30min respectively, obtain 20-25 μm lithium slag powder and carbide slag powder by sieving;

[0065] Step 2: Get 5.1 parts of lithium slag powder, 5.1 parts of water and mix them with wet grinding for 20 minutes to obtain 10.2 parts of ultrafine lithium slag slurry;

[0066] Step 3: get 2 parts of calcium carbide slag powder, 4 parts of water and mix and wet grind for 20 minutes to obtain 6 parts of nano carbide slag slurry;

[0067] Step 4: Take 10.2 parts of ultrafine lithium slag slurry, 6 parts of nano carbide slag slurry and 28.9 parts of cement, 0.3 part of calcium sulfate, 0.2 part of sodium citrate, 70 parts of river sand, and 96 parts of crushed slag obtained in steps 2 and 3. Stone, 8.9 parts of mixing water, 1.2 parts of water reducer, 0.3 parts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com