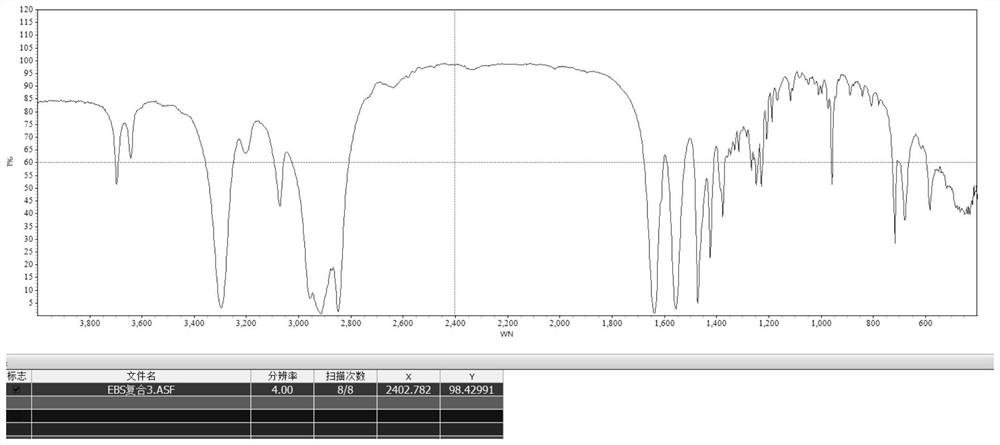

Synthesis method of EBS-containing composite dispersant with low volatility and low acid value

A composite dispersant and synthesis method technology, applied in the synthesis of low acid value composite dispersant, low volatility field, can solve the problems of low volatility, high volatile content, unsatisfactory dispersion effect of EBS composite dispersant, etc., to achieve Effects of improving ductility, increasing thermal decomposition temperature, and improving yellowing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

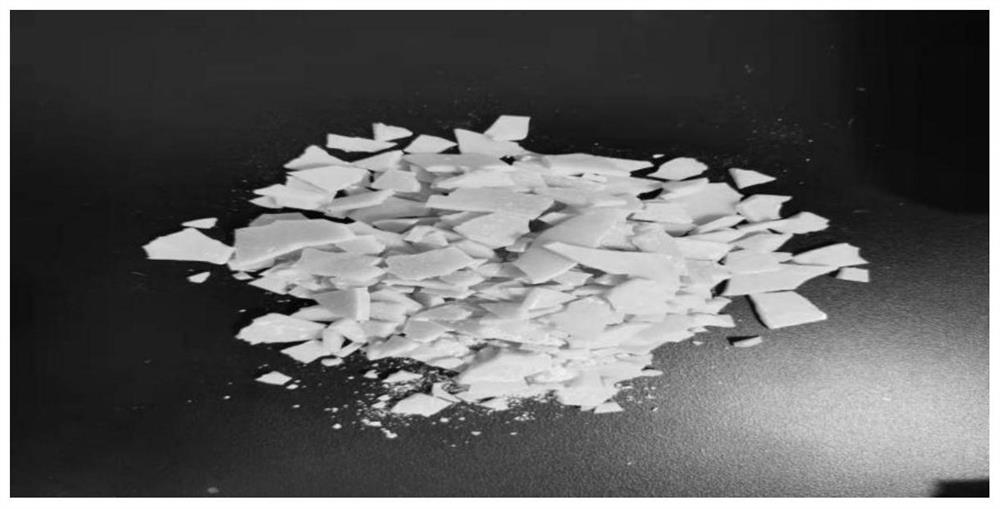

[0042] Weigh 85.2 grams (0.3mol) of stearic acid and 9 grams of polyethylene wax, put them all into a three-necked flask, heat up to 90°C, and after all the raw materials are melted and mixed uniformly, add 9.02 grams (0.15mol) of ethylenediamine ) through the dropping funnel, evenly added dropwise into the flask, and the dropping continued for 0.7 hours. After the dropping was completed, the temperature was raised to 200°C, and kept at a constant temperature for 1.5 hours; after the constant temperature was completed, 13 grams of magnesium oxide and 7 gram, was added to a three-necked flask, and mixed uniformly for no less than 30 minutes; then the product was filtered and poured into a stainless steel pan, cooled naturally, and crushed to obtain a slightly yellow solid product.

Embodiment 2

[0044] Weigh 85.2 grams (0.3mol) of stearic acid and 9 grams of polyethylene wax, put them all into a three-necked flask, heat up to 90°C, and after all the raw materials are melted and mixed uniformly, add 9.02 grams (0.15mol) of ethylenediamine ) through the dropping funnel, evenly added dropwise into the flask, and the dropping continued for 0.7 hours. 7 grams, was added to a three-necked flask, and mixed uniformly for no less than 30 minutes; then the product was filtered and poured into a stainless steel plate, and after natural cooling, it was crushed to obtain a yellowish solid product.

Embodiment 3

[0046] Weigh 85.2 grams (0.3mol) of stearic acid and 9 grams of polyethylene wax, put them all into a three-necked flask, heat up to 90°C, and after all the raw materials are melted and mixed uniformly, add 9.02 grams (0.15mol) of ethylenediamine ) through the dropping funnel, evenly added dropwise into the flask, and the dropping continued for 0.7 hours. After the dropping was completed, the temperature was raised to 200°C, and kept at a constant temperature for 1.5 hours; Add 13 grams into a three-necked flask, and mix evenly for no less than 30 minutes; then filter the product and pour it into a stainless steel plate, cool it down naturally, and break it to get a yellowish solid product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com