XPE air duct for automobile and preparation method of XPE air duct

A technology for air ducts and automobiles, which is applied in the field of XPE air ducts for automobiles and its preparation. It can solve problems such as the impact on the health of passengers, and achieve the effects of inhibiting the growth and reproduction of bacteria, good antibacterial and antifungal properties, and improving air quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

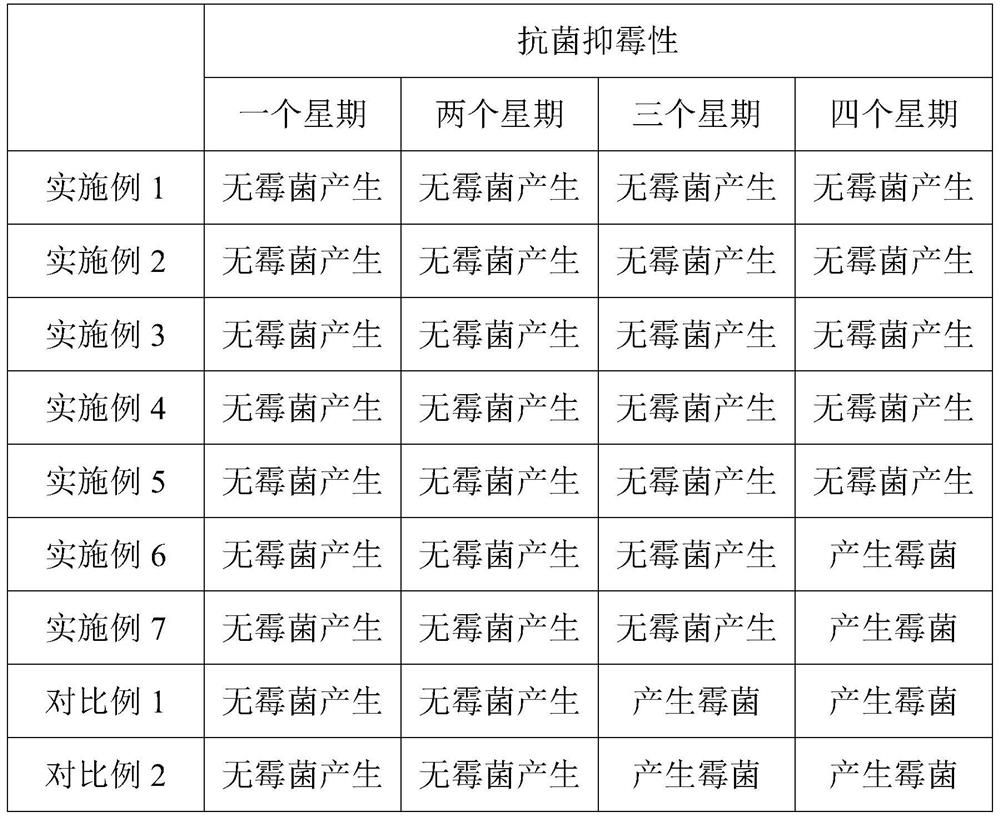

Examples

Embodiment 1

[0061] This embodiment provides an XPE air duct for automobiles and a preparation method thereof. The raw materials for the preparation of the XPE air duct include the following components in parts by weight:

[0062] 80 parts of polyethylene, 20 parts of sodium bicarbonate, 15 parts of modified zinc oxide, 5 parts of calcium stearate, 2 parts of polyisocyanate crosslinking agent, 0.5 parts of pyrophosphate titanate coupling agent, 2 parts of antibacterial agent 1.5 parts of hexachlorocyclotriphosphorcyanine and 1 part of phthalocyanine blue;

[0063] The antibacterial agent is composed of nano-silver antibacterial agent and nano-zinc oxide antibacterial agent with a mass ratio of 1:3.

[0064] The preparation method of the above-mentioned XPE air duct for automobiles is as follows:

[0065] (1) The raw materials for the preparation of the XPE air duct were mixed for 50 minutes through an internal mixer to obtain a mixed dough;

[0066] (2) After preheating the extruder to 1...

Embodiment 2

[0071] This embodiment provides an XPE air duct for automobiles and a preparation method thereof. The raw materials for the preparation of the XPE air duct include the following components in parts by weight:

[0072] 50 parts of polyethylene, 10 parts of calcium carbonate, 8 parts of modified zinc oxide, 1 part of calcium stearate, 4 parts of polyisocyanate crosslinking agent, 0.5 part of pyrophosphate titanate coupling agent, 0.3 part of antibacterial agent, 1 part of hexachlorocyclotriphosphate cyanide and 2 parts of carbon black;

[0073] The antibacterial agent is composed of nano-silver antibacterial agent and nano-zinc oxide antibacterial agent with a mass ratio of 1:5.

[0074] The preparation method of the above-mentioned XPE air duct for automobiles is as follows:

[0075] (1) The raw materials for the preparation of the XPE air duct were mixed for 10 minutes through an internal mixer to obtain a mixed dough;

[0076] (2) After preheating the extruder to 90°C, plac...

Embodiment 3

[0081] This embodiment provides an XPE air duct for automobiles and a preparation method thereof. The raw materials for the preparation of the XPE air duct include the following components in parts by weight:

[0082] 100 parts of polyethylene, 35 parts of sodium bicarbonate, 20 parts of modified zinc oxide, 10 parts of calcium stearate, 8 parts of polyisocyanate crosslinking agent, 1.5 parts of pyrophosphate titanate coupling agent, 1.6 parts of antibacterial agent , 2 parts of hexachlorocyclotriphosphorus cyanide and 0.5 part of phthalocyanine green;

[0083] The antibacterial agent is composed of nano-silver antibacterial agent and nano-zinc oxide antibacterial agent in a mass ratio of 1:4.

[0084] The preparation method of the above-mentioned XPE air duct for automobiles is as follows:

[0085] (1) The raw materials for the preparation of the XPE air duct were mixed for 70 minutes through an internal mixer to obtain a mixed dough;

[0086] (2) After preheating the extru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com