Laser-induced formed mother-of-pearl layered steel bond hard alloy and preparation method thereof

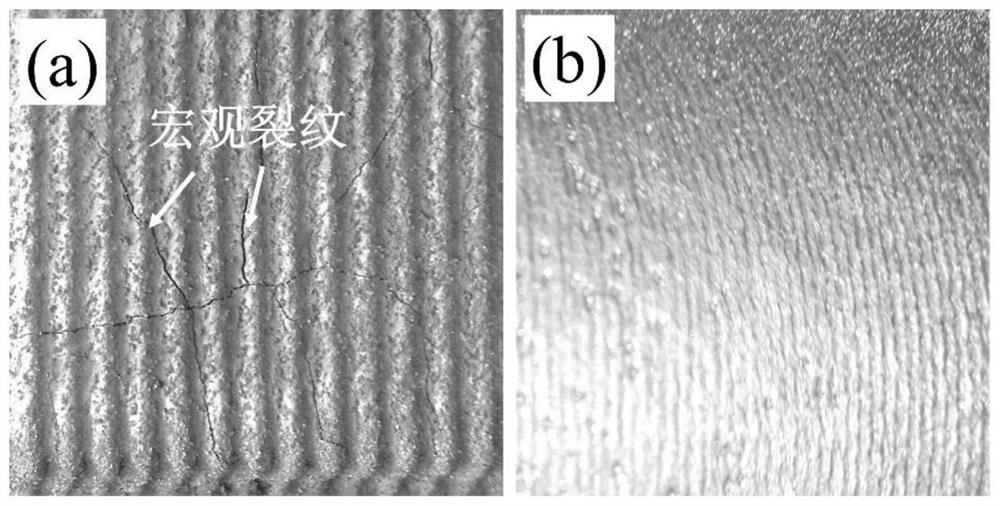

A steel-bonded hard alloy, laser-induced technology, applied in laser welding equipment, metal processing equipment, coatings, etc., can solve problems such as laser cladding steel-bonded hard alloy application problems, achieve significant energy dissipation effect, Controlling the Effects of Extensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

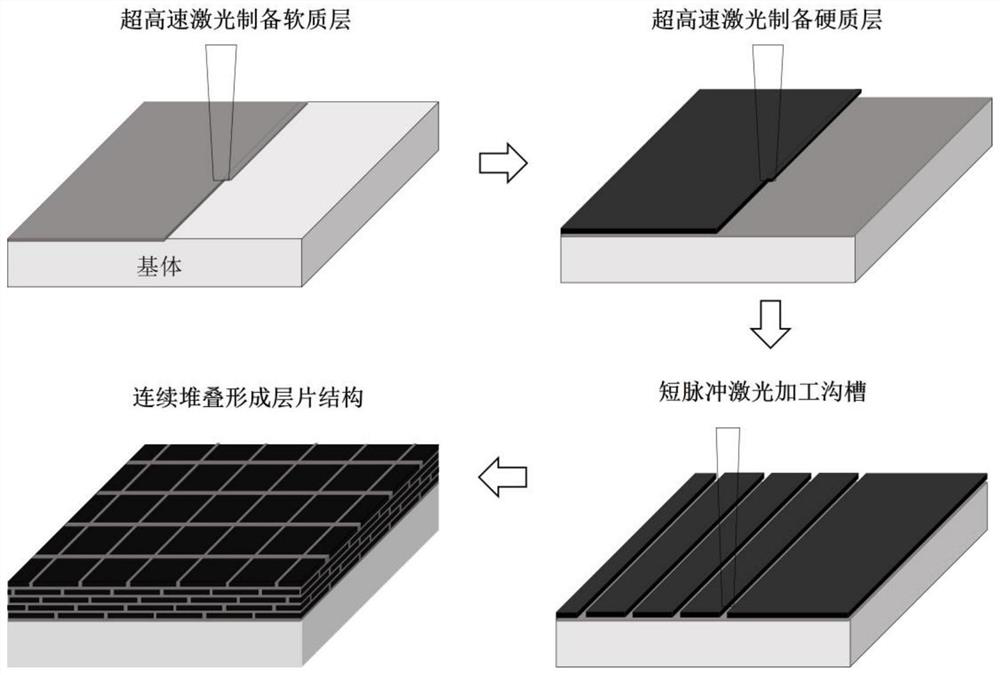

[0025] Laser-induced forming method of imitating mother-of-pearl layered steel-bonded cemented carbide:

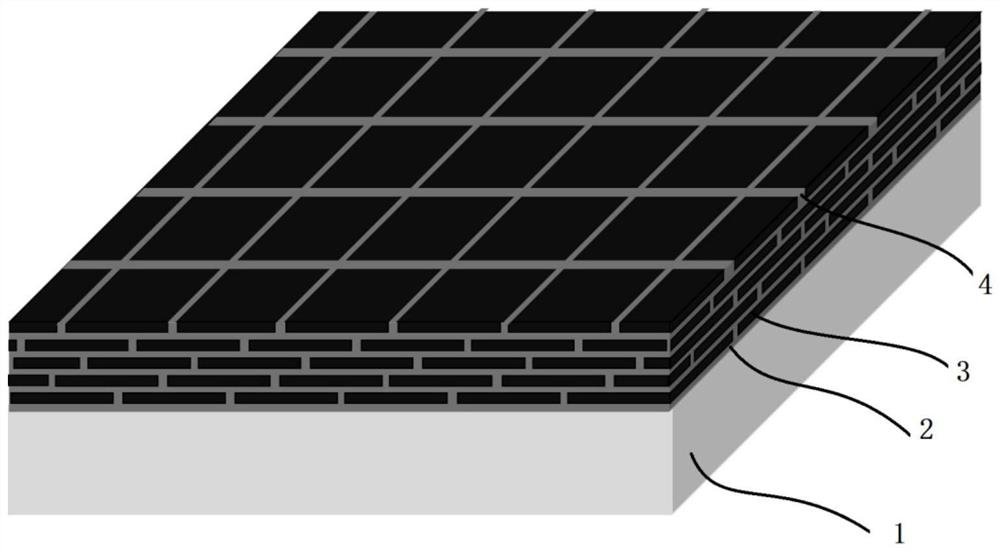

[0026] (1) The layered steel-bonded cemented carbide structure is composed of TiC hard ceramic material layers and 316L soft material layers alternately, forming a "mud brick" structure similar to natural mother-of-pearl;

[0027] (2) Using ultra-high-speed laser cladding technology to prepare each layer of TiC hard ceramic material layer and 316L soft material layer of layered steel-bonded cemented carbide, the laser power is 3000W and 1800W respectively, and the scanning speed is 12m / min , after the preparation of each layer of material, the picosecond laser processing technology is used to prepare the grid structure in the "mud brick" structure. The laser parameters are: power 35W, spot diameter 30 microns. Through continuous accumulation and forming, a steel-bonded cemented carbide with a layered structure imitating mother of pearl is formed;

[0028] (3) The single-l...

Embodiment 2

[0032] Laser-induced forming method of imitating mother-of-pearl layered steel-bonded cemented carbide:

[0033] (1) The layered steel-bonded cemented carbide structure is composed of TiC hard ceramic material layers and 304 stainless steel soft material layers alternately, forming a "mud brick" structure similar to natural mother-of-pearl;

[0034] (2) Using ultra-high-speed laser cladding technology to prepare each layer of TiC hard ceramic material layer and 304 stainless steel soft material layer of layered steel-bonded cemented carbide, the laser power is 2800W and 1600W respectively, and the scanning speed is 10m / min, after the preparation of each layer of material, the picosecond laser processing technology was used to prepare the grid structure in the "mud brick" structure. The laser parameters were: power 30W, spot diameter 30 microns. Through continuous accumulation and forming, a steel-bonded cemented carbide imitating mother-of-pearl layered structure is formed; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com