Seasoning and preparation method thereof

A seasoning and raw material technology, which is applied in the field of seasoning and its preparation, can solve the problem that the seasoning has no nutritional and health care effects, and achieve the effect of convenient eating, enhanced base flavor, and sweet and fresh taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

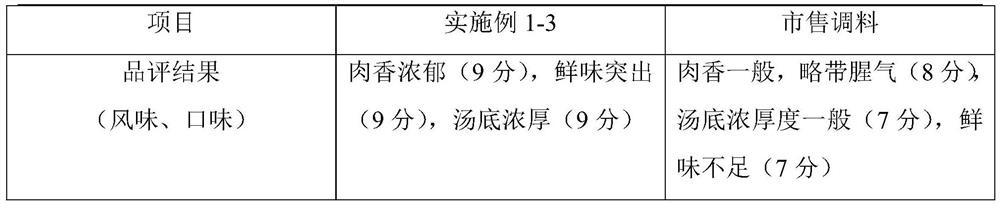

Examples

preparation example Construction

[0020] A seasoning and its preparation method according to the present invention, comprising the following raw materials in parts by mass: 10-20 parts of polypeptide powder, 8-12 parts of yeast extract, 1-3 parts of maca powder, 15-25 parts of soft water , 4-6 parts of tremella polysaccharide, 1-3 parts of glucose, 5-8 parts of white sugar, 2-5 parts of edible salt, 1-2 parts of vegetable oil, 0.5-1.0 parts of citric acid, 0.1-0.1- 0.4 parts. Wherein the polypeptide powder is plant polypeptide, and the vegetable oil is safflower seed oil.

[0021] For further better explanation, the present invention provides the following specific examples:

Embodiment 1

[0023] Raw materials according to mass fraction: 20 parts of polypeptide powder, 12 parts of yeast extract, 3 parts of maca powder, 25 parts of soft water, 6 parts of tremella polysaccharide, 3 parts of glucose, 6 parts of white sugar, 2 parts of edible salt, 1 part of vegetable oil , 0.5 parts of citric acid, and 0.1 parts of disodium nucleotides.

[0024] According to above-mentioned raw materials, a kind of preparation method of seasoning is provided, comprising the following steps:

[0025] Step 1: Maillard reaction: add soft water to the reaction tank, mix polypeptide powder, white fungus polysaccharide and yeast extract, heat to 110-120°C in the autoclave, and keep for 1.0 hour;

[0026] Step 2: Lower the temperature of the reaction liquid feed liquid to 96-98°C, add maca powder and glucose, and continue the reaction for 0.5h;

[0027] Step 3: Lower the temperature of the reaction liquid in step 2 to 80-85°C, add white sugar, edible salt, vegetable oil, citric acid, and...

Embodiment 2

[0030] Raw materials according to mass fraction: 15 parts of polypeptide powder, 10 parts of yeast extract, 2 parts of maca powder, 20 parts of soft water, 5 parts of tremella polysaccharide, 2 parts of glucose, 6 parts of white sugar, 2 parts of edible salt, 1 part of vegetable oil , 0.5 parts of citric acid, and 0.1 parts of disodium nucleotides.

[0031] According to above-mentioned raw materials, a kind of preparation method of seasoning is provided, comprising the following steps:

[0032] Step 1: Maillard reaction: add soft water to the reaction tank, mix polypeptide powder, white fungus polysaccharide and yeast extract, heat to 110-120°C in the autoclave, and keep for 1.0 hour;

[0033] Step 2: Lower the temperature of the reaction liquid feed liquid to 96-98°C, add maca powder and glucose, and continue the reaction for 0.5h;

[0034] Step 3: Lower the temperature of the reaction liquid in step 2 to 80-85°C, add white sugar, edible salt, vegetable oil, citric acid, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com