Anodic oxide film dyeing stabilizer and anodic oxide film dyeing method

A technology of anodized film and dyeing method, applied in the field of anodized film dyeing stabilizer and anodized film dyeing, can solve the problems of affecting the use function and effect, single additive function, loss of dyeing function, etc., to achieve stable pH value, reduce The effect of management difficulty and short answer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

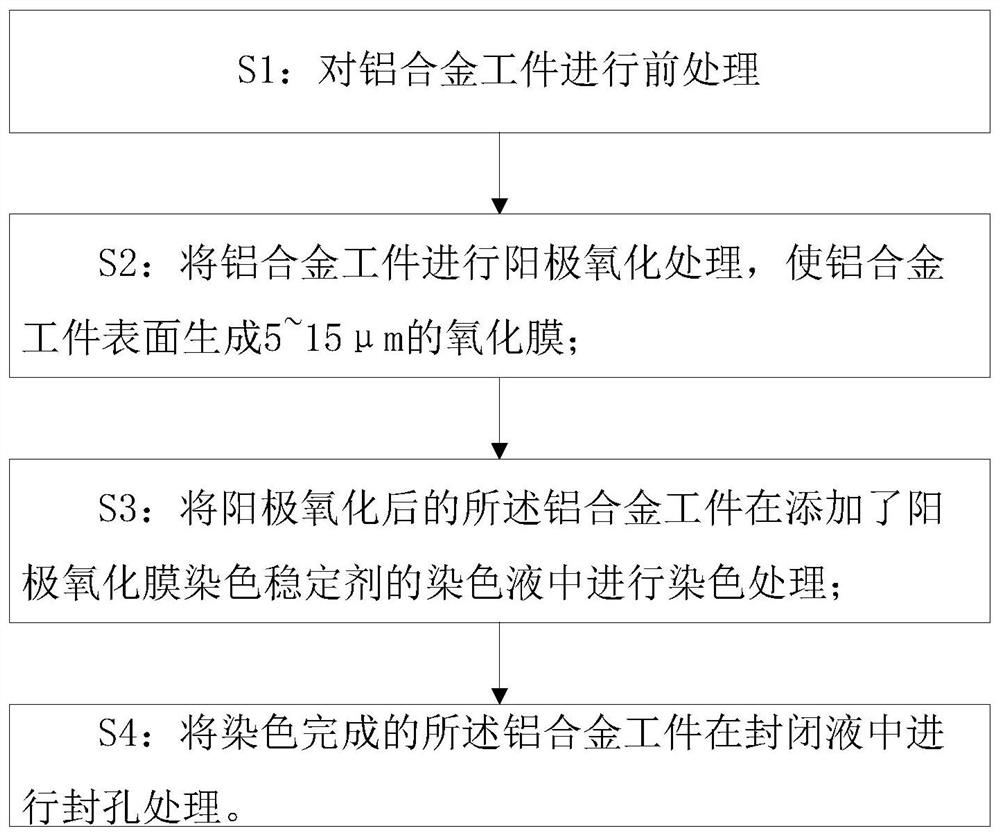

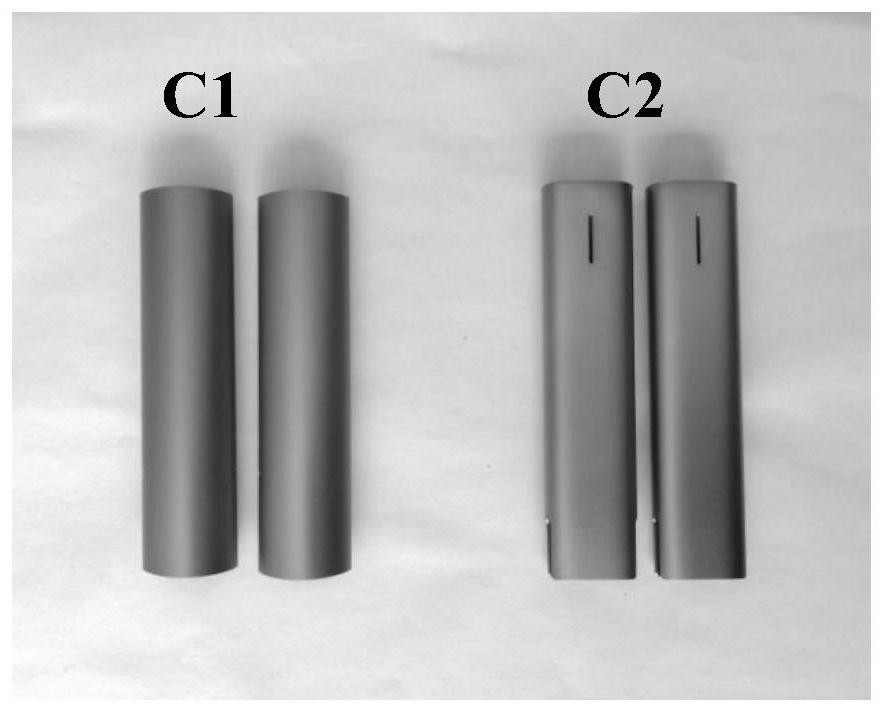

[0037] S1: Use 220-mesh glass beads to sandblast the aluminum alloy workpiece, and then chemically polish it to control the surface gloss of the aluminum alloy to 60 Keles;

[0038] S2: Anodizing the pretreated aluminum alloy workpiece in a 20% sulfuric acid solution to form a 10 μm oxide film on the surface of the aluminum alloy workpiece;

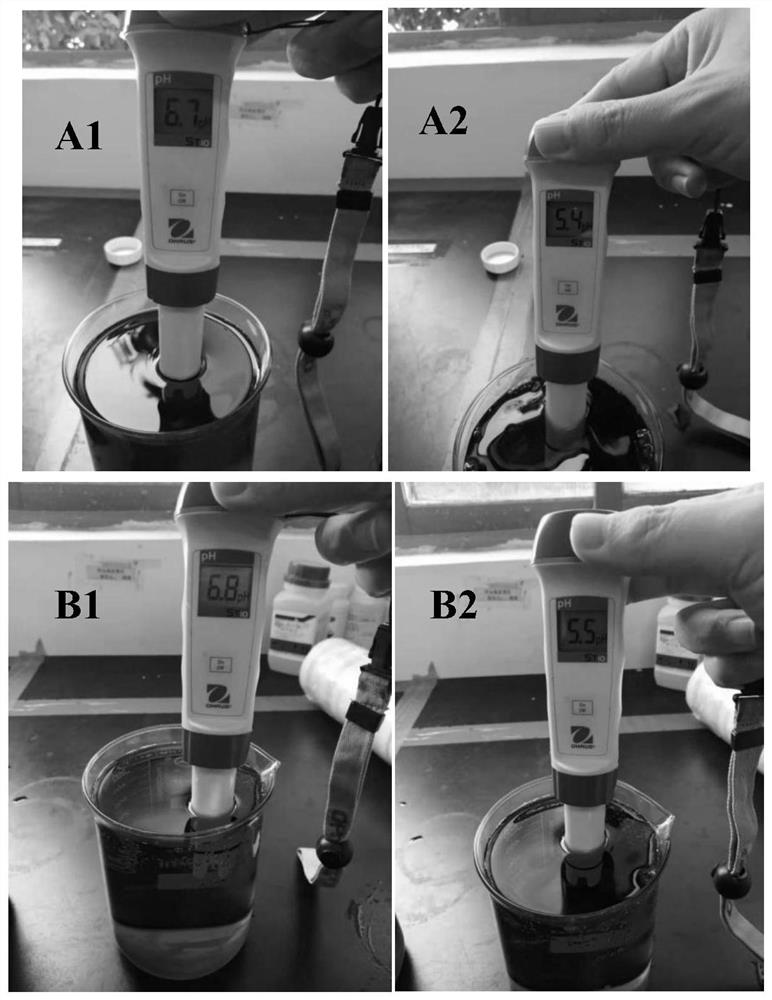

[0039]S3: The anodized aluminum alloy workpiece is dyed in a dyeing solution containing 0.5g / L Okuno 102 dyeing agent and 5mL / L anodized film dyeing stabilizer. The dyeing condition is soaking at 33°C for 200s ;

[0040] Wherein the anodized film dyeing stabilizer includes the following components: 100g / L pH buffer (acetic acid / sodium acetate system, wherein the mass ratio of acetic acid to sodium acetate is 1.8:10), 15g / L Pingping plus O-25, 10g / L L sodium dodecyl sulfonate, 15g / L sodium diacetate, water as solvent.

[0041] S4: The dyed aluminum alloy workpiece is sealed in a sealing solution. The sealing agent is Okuno's DX-500 high-...

Embodiment 2

[0044] The difference with Example 1 is that wherein the anodized film dyeing stabilizer comprises the following components: 120g / LpH buffer (acetic acid / sodium acetate system, wherein the mass ratio of acetic acid to sodium acetate is 1.8:10), 12g / L pH buffer Add O-25, 12g / L sodium dodecylsulfonate, 20g / L sodium diacetate, and use water as the solvent.

Embodiment 3

[0046] The difference with Example 1 is that wherein the anodized film dyeing stabilizer comprises the following components: 130g / LpH buffer (acetic acid / sodium acetate system, wherein the mass ratio of acetic acid to sodium acetate is 1.8:10), 8g / L flat Add O-25, 15g / L sodium dodecylsulfonate, 25g / L sodium diacetate, and use water as the solvent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com