Liquid ejection nozzle

A technology for injecting nozzles and liquids, which is applied to fuel injection devices, special fuel injection devices, engine components, etc., and can solve problems such as increased flow spray, loss, and inability to achieve diffusion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

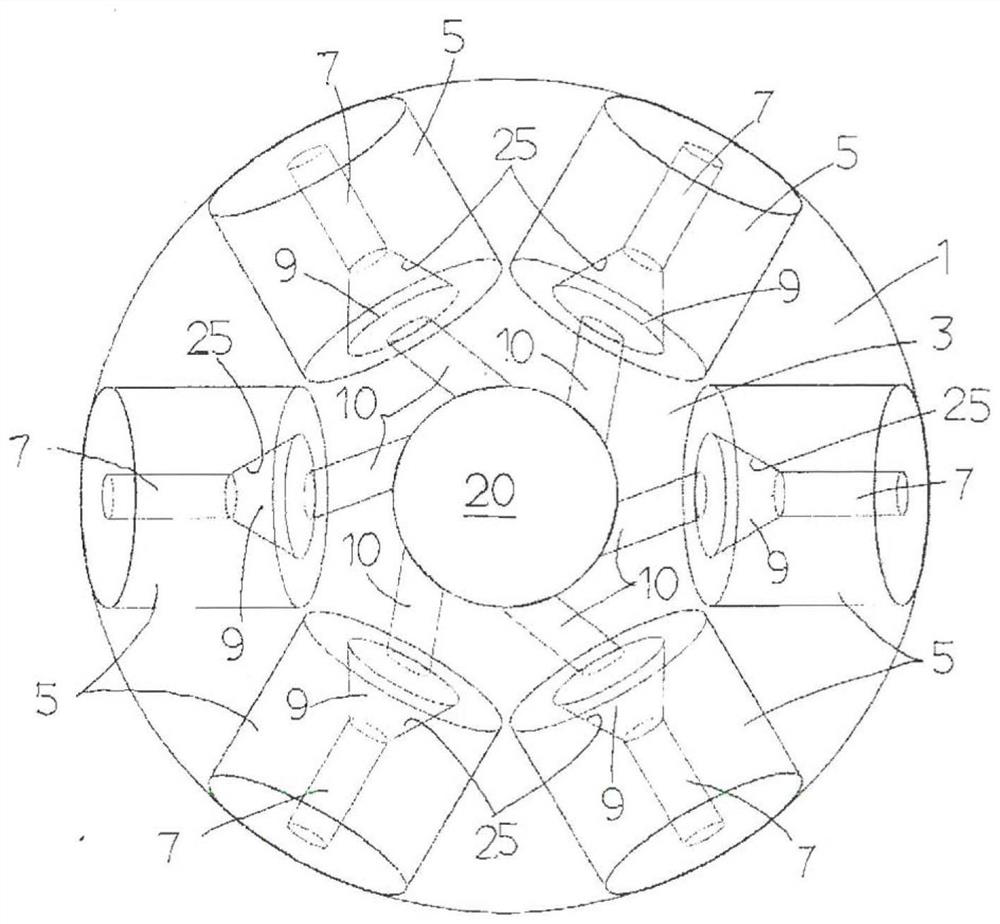

[0030] The multi-nozzle structure of the liquid injection nozzle of the present invention is preferably applied to a nozzle for spraying a liquid such as a fuel injection device equipped with a diesel engine, an exhaust gas purification device for spraying a liquid such as ammonia water or urea water, or the like.

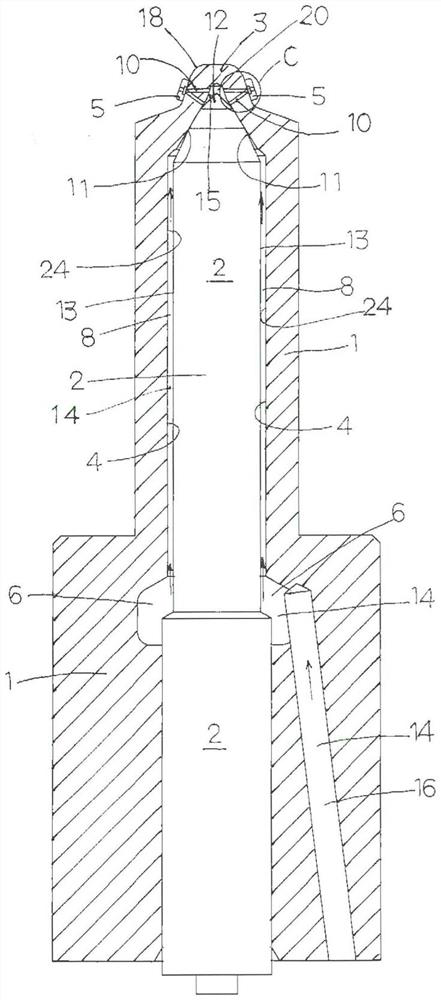

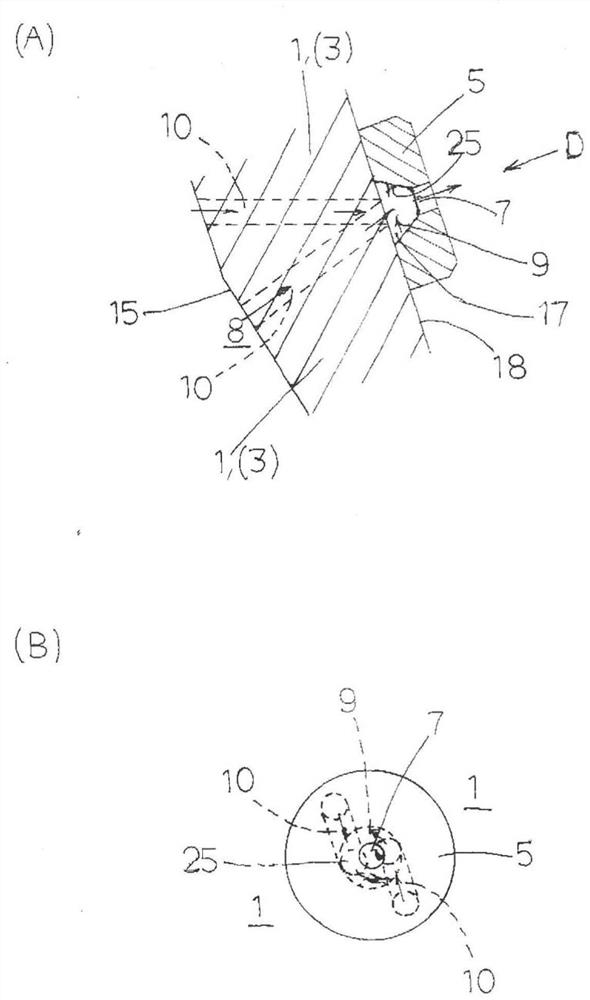

[0031] Hereinafter, embodiments of the liquid ejection nozzle will be described with reference to the drawings. First, refer to figure 1 and figure 2 , the schematic structure of the first embodiment of the liquid ejection nozzle will be described. This liquid injection nozzle can be applied to, for example, a fuel injection nozzle equipped with a diesel engine or a gasoline engine, or an exhaust gas purification device that sprays a liquid such as ammonia water or urea water. The liquid injection nozzle mainly includes: a tubular nozzle main body 1, which is fixed to the mounting portion of the engine, injection device, combustion equipment, etc., and has liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com